Abstract

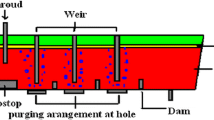

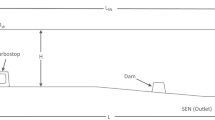

The optimization of flow control devices in a single-slab continuous casting tundish was carried out by physical modeling, and the optimized scheme was presented. With the optimal tundish configuration, the minimum residence time of liquid steel was increased by 1.4 times, the peak concentration time was increased by 97%, and the dead volume fraction was decreased by 72%. A mathematical model for molten steel in the tundish was established by using the fluid dynamics package Fluent. The velocity field, concentration field, and the residence time distribution (RTD) curves of molten steel flow before and after optimization were obtained. Experimental results showed that the reasonable configuration with flow control devices can improve the fluid flow characteristics in the tundish. The results of industrial application show that the nonmetallic inclusion area ratio in casting slabs is decreased by 32% with the optimal tundish configuration.

Similar content being viewed by others

References

Y.P. Bao, W. Jiang, B.M. Xu, et al., Fluid flow in tundish due to different type arrangement of weir and dam, J. Univ. Sci. Technol. Beijing, 9(2002), No.1, p.13.

C.J. Zhang, L. Wang, K.K. Cai, et al., Influence of flow control devices on metallurgical effects in a large capacity tundish, J. Univ. Sci. Technol. Beijing, 9(2002), No.6, p.412.

K.M. Godiwalla, S.K. Sinha, and C.S. Sivaramakrishnan, Statistical analysis of residence time distribution of fluid elements in continuous casting water model tundish with one side entry, Steelmaking Conf. Proc., 77(1994), p.703.

S.K. Sinha, K.M. Godiwalla, D.K. Shaw, and C.S. Sivaramakrishnan, Fluid flow behaviour in a water model tundish under open, submerged and modified inlet conditions, Scand. J. Metall., 30(2001), p.103.

Y.P. Bao, B.M. Xu, G.L. Liu, et al., Design optimization of flow control device for multi-strand tundish, J. Univ. Sci. Technol. Beijing, 10(2003), No.2, p.21.

S.H. Peng, X.F. Li, S.T. Qiu, et al., Application of computational fluid dynamics to analysis of metallurgical process for continuous casting tundishes, J. Univ. Sci. Technol. Beijing, 11(2004), No.3, p.207.

Z.Y. Wei, Y.P. Bao, J.H. Liu, et al., Orthogonal analysis of water model study on the optimization of flow control devices in a six-strand tundish, J. Univ. Sci. Technol. Beijing, 14(2007), No.2, p.118.

Q.F. Hou and Z.S. Zou, Numerical and physical simulation of flow patterns in a swirling flow tundish, Steel Res. Int., 76(2005), p.726.

J.J. Wang, Y.P. Bao, and Y. Qu, Metallurgy in Tundish, Metallurgical Industry Press, Beijing, 2001, p.20, 27.

J.G. Liu, H.C. Yan, L. Liu, et al., Water modeling of optimizing tundish flow field, J. Iron Steel Res. Int., 14(2007), No.3, p.13.

L.F. Zhang, Validation of the numerical simulation of fluid flow in the continuous casting tundish, J. Univ. Sci. Technol. Beijing, 12(2005), No.2, p.116

N. Cao and M.Y. Zhu, Optimization of flow control devices in a slab continuous casting tundish, J. Mater. Metall, 6(2007), p.110.

Y.F. Wang, G.H. Wen, P. Tang, et al., Mathematical modeling of fluid flow, heat transfer and inclusion transport in a four strand tundish, J. Univ. Sci. Technol. Beijing, 14(2007), No.1, p.22.

D. Mazumdar and R.I.L. Guthrie, Physical and mathematical modeling of continuous casting tundish systems, ISIJ Int., 39(1999), p.524.

A.K. Sinha and Y. Sahai, Mathematical modeling of inclusion transport and removal in continuous casting tundishes, ISIJ Int., 35(1993), p.556.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ding, N., Bao, Yp., Sun, Qs. et al. Optimization of flow control devices in a single-strand slab continuous casting tundish. Int J Miner Metall Mater 18, 292–296 (2011). https://doi.org/10.1007/s12613-011-0436-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-011-0436-7