Abstract

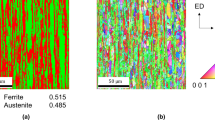

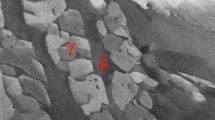

The hot deformation characteristics of 1.4462 duplex stainless steel (DSS) were analyzed by considering strain partitioning between austenite and ferrite constituents. The individual behavior of ferrite and austenite in microstructure was studied in an iso-stress condition. Hot compression tests were performed at temperatures of 800–1100°C and strain rates of 0.001–1 s−1. The flow stress was modeled by a hyperbolic sine constitutive equation, the corresponding constants and apparent activation energies were determined for the studied alloys. The constitutive equation and law of mixture were used to measure the contribution factor of each phase at any given strain. It is found that the contribution factor of ferrite exponentially declines as the Zener-Hollomon parameter (Z) increases. On the contrary, the austenite contribution polynomially increases with the increase of Z. At low Z values below 2.6.×1015 (lnZ=35.5), a negative contribution factor is determined for austenite that is attributed to dynamic recrystallization. At high Z values, the contribution factor of austenite is about two orders of magnitude greater than that of ferrite, and therefore, austenite can accommodate more strain. Microstructural characterization via electron back-scattered diffraction (EBSD) confirms the mechanical results and shows that austenite recrystallization is possible only at high temperature and low strain rate.

Similar content being viewed by others

References

A. Itman Filho, J.M.D.A. Rollo, R.V. Silva, and G. Martinez, Alternative process to manufacture austenitic-ferritic stainless steel wires, Mater. Lett., 59(2005), No. 10, p. 1192.

I. Gurrappa and C.V. Krishna Reddy, Characterization of newly developed structural DMR-1700 steel and comparison with different steels for chemical applications, J. Mater. Process. Technol., 182(2007), p. 195.

C.M. Garzón and A.P. Tschiptschin, EBSD texture analysis of a high temperature gas nitrided duplex stainless steel, Mater. Sci. Eng. A, 441(2006), No. 1–2, p. 230.

J.M. Cabrera, A. Mateo, L. Llanes, J.M. Prado, and M. Anglada, Hot deformation of duplex stainless steels, J. Mater. Process. Technol., 143–144(2003), p. 321.

H.J. McQueen and D.L. Bourell, Formability and Metallurgical Structure, Edited by A.K. Sachdev and J.D. Embury, TMS, Warrendale, 1986, p. 341.

C. Huang Flow Stress, Restoration and Precipitation Behavior, and Modeling for Two Ti-Nb Stabilized IF Steels in the Ferrite Region [Dissertation], University of British Columbia, Canada, 1999.

H.J. McQueen, N.D. Ryan, E. Evangelista, and X. Xia, Flow stresses, grain and subgrain structures developed by hot working in as-cast 409 stainless steel, [in] Proceedings of the 34th Mechanical Working Steel Processing Conference, Iron and Steel Society of AIME, Warrendale, 1993, p. 101.

G.S. Reis, A.M. Jorge Jr., and O. Balancin, Influence of the microstructure of duplex stainless steels on their failure characteristics during hot deformation, Mater. Res., 3(2000), No. 2, p. 31.

E. Evangelista, H.J. McQueen, B. Verlinden, and M. Barteri, Hot forming of duplex stainless steels, [in] Proceedings of the 3rd European Congress “Stainless Steels’ 99 — Science and Market”, Milano, 1999, p. 253.

F. Tehovnik, B. Arzenšek, B. Arh, D. Skobir, B. Pirnar, and B. Žužek, Microstructure evolution in SAF 2507 super duplex stainless steel, Mater. Technol., 45(2011), No. 4, p. 33.

P.L. Mao, K. Yang, and G.Y. Su, Hot deformation behavior of an as-cast duplex stainless steel, J. Mater. Sci. Technol., 19(2003), No. 4, p. 379.

E. Evangelista, H.J. McQueen, M. Niewczas, and M. Cabibbo, Hot workability of 2304 and 2205 duplex stainless steels, Can. Metall. Q., 43(2004), No. 3, p. 339.

A. Momeni, S.M. Abbasi, and A. Shokuhfar, Hot compression behavior of as-cast precipitation-hardening stainless steel, J. Iron Steel Res. Int., 14(2007), No. 5, p. 66.

A. Momeni, A. Shokuhfar, and S.M. Abbasi, Dynamic recrystallization of a Cr-Ni-Mo-Cu-Ti-V precipitation hardenable stainless steel, J. Mater. Sci. Technol., 23(2007), p. 775.

M.S. Chen, Y.C. Lin, and X.S. Ma, The kinetics of dynamic recrystallization of 42CrMo steel, Mater. Sci. Eng. A, 556(2012), p. 260.

G. Niewielski, K. Radwański, and D. Kuc, The influence of hot-working processing on plasticity and structure of duplex steel, Arch. Mater. Sci. Eng., 28(2007), No. 6, p. 325.

P. Cizek, B.P. Wynne, and W.M. Rainforth, EBSD investigation of the effect of strain path changes on the microstructure and texture of duplex stainless steel during hot deformation, J. Phys. Conf. Ser., 26(2006), p. 331.

H. Farnoush, A. Momeni, K. Dehghani, J. Aghazadeh Mohandesi, and H. Keshmiri, Hot deformation characteristics of 2205 duplex stainless steel based on the behavior of constituent phases, Mater. Des., 31(2010), p. 220.

L.E. Hernandez-Castillo, J.H. Beynon, C. Pinna, and S. Van Der Zwaag, Micro-scale strain distribution in hotworked duplex stainless steel, Steel Res. Int., 76(2005), No. 2–3, p. 137.

A. Dehghan-Manshadi and P.D. Hodgson, Effect of δ-ferrite co-existence on hot deformation and recrystallization of austenite, J. Mater. Sci., 43(2008), No. 18, p. 6272.

A. Momeni, K. Dehghani, and X.X. Zhang, Mechanical and microstructural analysis of 2205 duplex stainless steel under hot working condition, J. Mater. Sci., 47(2012), p. 2966.

L. Duprez, B.C. De Cooman, and N. Akdut, Hightemperature stress and strain partitioning in duplex stainless steel, Z. Metallkd., 93(2002) p. 236.

J. Johansson and M. Odén, Load sharing between austenite and ferrite in a duplex stainless steel during cyclic loading, Metall. Mater. Trans. A, 31(2000), p. 1557.

A. Iza-Mendia, A. Piñol-Juez, J.J. Urcola, and I. Gutierrez, Microstructural and mechanical behavior of a duplex stainless steel under hot working conditions, Metall. Mater. Trans. A, 29(1998), p. 2975.

O. Balancin, W.A.M. Hoffmann, and J.J. Jonas, Influence of microstructure on the flow behavior of duplex stainless steels at high temperatures, Metall. Mater. Trans. A, 31(2000), p. 1353.

L. Duprez, B.C. De Cooman, and N. Akdut, Flow stress and ductility of duplex stainless steel during hightemperature torsion deformation, Metall. Mater. Trans. A, 33(2002), p. 1931.

Y.C. Lin and X.M. Chen. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working, Mater. Des., 32(2011), p. 1733.

C.M. Sellars and W.J. McG. Tegart, Hot workability, Int. Mater. Rev., 17(1972), No. 1, p. 1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Momeni, A., Kazemi, S. & Bahrani, A. Hot deformation behavior of microstructural constituents in a duplex stainless steel during high-temperature straining. Int J Miner Metall Mater 20, 953–960 (2013). https://doi.org/10.1007/s12613-013-0820-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-013-0820-6