Abstract

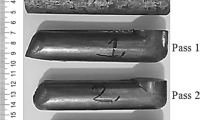

In this study, annealed pure copper was extruded using equal channel angular extrusion (ECAE) for a maximum of eight passes. The fatigue resistance of extruded specimens was evaluated for different passes and applied stresses using fatigue tests, fractography, and metallography. The mechanical properties of the extruded material were obtained at a tensile test velocity of 0.5 mm/min. It was found that the maximum increase in strength occurred after the 2nd pass. The total increase in ultimate strength after eight passes was 94%. The results of fatigue tests indicated that a significant improvement in fatigue life occurred after the 2nd pass. In subsequent passes, the fatigue life continued to improve but at a considerably lower rate. The improved fatigue life was dependent on the number of passes and applied stresses. For low stresses (or high-cycle fatigue), a maximum increase in fatigue resistance of approximately 500% was observed for the extruded material after eight passes, whereas a maximum fatigue resistance of 5000% was obtained for high-applied stresses (or low-cycle fatigue). Optical microscopic examinations revealed grain refinements in the range of 32 to 4 μm. A maximum increase in impact energy absorption of 100% was achieved after eight passes. Consistent results were obtained from fractography and metallography examinations of the extruded material during fatigue tests.

Similar content being viewed by others

References

V.M. Segal, V.I. Reznikov, A.E. Drobyshevskiy, and V.I. Kopylov, Plastic working of metals by simple shear, Russ. Metall., 1(1981), p. 99.

R. Daly, S. Zghal, and N. Njeh, Effects of annealing on the microstructure and properties of Cua1copper processed by equal channel angular extrusion, Phys. Procedia, 2(2009), No. 3, p. 677.

C. Koch, Nanostructured Materials Processing, Properties and Potential Applications, William Andrew Publishing, New York, 1953.

W.H. Huang, C.Y. Wu, P.W. Kao, and C.P. Chang, The effect of strain path and temperature on the microstructure developed in copper processed by ECAE, Mater. Sci. Eng. A, 366(2004), No. 2, p. 221.

L Kommel, I Hussainova, and O Volobueva, Microstructure and properties development of copper during severe plastic deformation, Mater. Des., 28(2007), No. 7, p. 1221.

A.Y. Vinogradov, V.V. Stolyarov, S. Hashimoto, and R.Z. Valiev, Cyclic behavior of ultrafine-grain titanium produced by severe plastic deformation, Mater. Sci. Eng. A, 318(2001), No. 1–2, p. 163.

H. Mughrabi and H.W. Höppel, Cyclic deformation and fatigue properties of very fine-grained metals and alloys, Int. J. Fatigue, 32(2010), No. 9, p. 1413.

Y. Estrin and A. Vinogradov, Fatigue behaviour of light alloys with ultrafine grain structure produced by severe plastic deformation: an overview, Int. J. Fatigue, 32(2010), No. 6, p. 898.

R.C. Zeng, H. Enhou, K. Wei, W. Dietze, K.U. Kainer, and A. Atrens, Influence of microstructure on tensile properties and fatigue crack growth in extruded magnesium alloy AM60, Int. J. Fatigue, 32(2010), No. 2, p. 411.

G Purcek, O Saray, I Karaman, and T. Kucukomeroglu, Effect of severe plastic deformation on tensile properties and impact toughness of two-phase Zn-40Al alloy, Mater. Sci. Eng. A, 490(2008), No. 1–2, p. 403.

M.K. Wong, P.W. Kao, J.T. Lui, C.P. Chng, and P.W. Kao, Cyclic deformation of ultrafine-grained aluminum, Acta Mater., 55(2007), No. 2, p. 715.

R. Lapovok, C. Loader, F.H. Dalla Torre, and S.L. Semiatin, Microstructure evolution and fatigue behavior of 2124 aluminum processed by ECAE with back pressure, Mater. Sci. Eng. A, 425(2006), No. 1–2, p. 36.

P. Gabor, D. Canading, H.J. Maier, R.J. Hellming, Z. Zuberova, and J. Estrin, The influence of zirconium on the low-cycle fatigue response of ultrafine-grained copper, Metall. Mater. Trans. A, 38(2007), No. 9, p. 1916.

H.W. Höppel, M. Brunnbauer, H. Mughrabi, R.Z. Valiev, and A.P. Zhilyaev, Cyclic deformation behaviour of ultrafine grain size copper produced by equal channel angular extrusion, [in] Werkstoffwoche-Partnerschaft eds. Materials Week 2000 — Proceedings, Frankfurt, 2000, p. 1.

P. Lukáš, L. Kunz, and M. Svoboda, Fatigue of ultrafine-grained copper, [in] Proceedings of the 6th International Conference on Low Cycle Fatigue (LCF6), Berlin, 2008, p. 295.

H. Mughrabi, H.W. Höppel, M. Kautz, and R.Z. Valiev, Annealing treatments to enhance thermal and mechanical stability of ultrafine-grained metals produced by severe plastic deformation, Z. Metallkd., 94(2003), No. 10, p. 1079.

T.L. Jones, J.P. Labukas, B.E. Placzankis, and K. Kondoh, Ballistic and Corrosion Analysis of New Military-Grade Magnesium Alloys AMX602 and ZAXE1711 for Armor Applications, US Army Research Laboratory, ARL-TR-5931, 2012.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nemati, J., Majzoobi, G.H., Sulaiman, S. et al. Improvements in the microstructure and fatigue behavior of pure copper using equal channel angular extrusion. Int J Miner Metall Mater 21, 569–576 (2014). https://doi.org/10.1007/s12613-014-0943-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-0943-4