Abstract

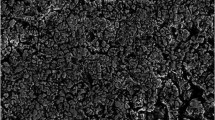

Since the white layer thickness influences the surface quality of the machined specimens using electrical discharge machining process, the prediction of such parameter is highly important in the present scenario. Adaptive network based fuzzy inference system based white layer thickness prediction on machining processed silicon steel has been attempted in the present study. Three machining process parameters such as open circuit voltage, peak current and duty factor have been utilized for the training purpose owing their importance on determining white layer thickness. The accuracy of the prediction has been analyzed by comparing the predicted values from the architecture testing with the real time measured values. From the experimental results, it has been found that the developed adaptive network based fuzzy inference system can predict the average white layer thickness in an efficient way with accuracy of 96.8%. It has also been observed that the electrical process parameters have highly contributed on determining average white layer thickness.

Similar content being viewed by others

References

Muthuramalingam T, Mohan B (2013) Influence of discharge current pulse on machinability in electrical discharge machining. Mater Manuf Process 28(4):375–380

Patowari PK, Mishra UK, Saha P, Mishra PK (2011) Surface integrity of C-40 steel processed with WC-Cu powder metallurgy green compact tool in EDM. Mater Manuf Process 26(5):668–676

Ekmekci B, Elkoca O, Tekkaya AE, Erden A (2005) Residual stress state and hardness depth in electric discharge machining: de-ionized water as dielectric liquid. Mach Sci Technol 9(1):39–61

Rajendran S, Marimuthu K, Sakthivel M (2012) Study of crack formation and resolidified layer in EDM process on T90Mn2W50Cr45 tool steel. Mater Manuf Process 28(6):664–669

Muthuramalingam T, Mohan B, Jothilingam A (2014) Effect of tool electrode resolidification on surface hardness in electrical discharge machining. Mater Manuf Process 29(11-12):1374–1380

Vural Y, Ingham DB, Pourkashanian M (2009) Performance prediction of a proton exchange membrane fuel cell using the ANFIS model. Int J Hydrogen Energ 34(22): 9181–9187

Lo SP (2003) An adaptive-network based fuzzy inference system for prediction of workpiece surface roughness in end milling. J Mater Process Technol 142(3): 665-675

Aydin M, Karakuzu C, Ucar M, Cengiz A, Cavuslu MA (2013) Prediction of surface roughness and cutting zone temperature in dry turning processes of AISI304 stainless steel using ANFIS with PSO learning. Int J Adv Manuf Technol 67(1–4): 957–967

Benardos PG, Vosniakos GC (2003) Predicting surface roughness in machining: a review. Int J Mach Tool Manuf 43(8):833–844

Li C, Xu X, Li Y, Tong H, Ding S, Kong Q, Zhao L, Ding J (2019) Effects of dielectric fluids on surface integrity for the recast layer in high speed EDM drilling of nickel alloy. J Alloys Compd 783(1):95–102

Li CJ, Li Y, Tong H, Zhao L (2016) Thinning process of recast layer in hole drilling and trimming by EDM. Proc CIRP 42(1):575–579

Wu X, Li S, Jia Z, Xin B, Yin X (2019) Using WECM to remove the recast layer and reduce the surface roughness of WEDM surface. J Mater Process Technol 268(1):140–148

Muthuramalingam T (2019) Effect of diluted dielectric medium on spark energy in green EDM process using TGRA approach. J Clean Prod 238(1):117894

Izquierdo B, Plaza S, Sánchez JA, Pombo I, Ortega N (2012) Numerical prediction of heat affected layer in the EDM of aeronautical alloys. Appl Surf Sci 259(1):780–790

Yildiz Y (2016) Prediction of white layer thickness and material removal rate in electrical discharge machining by thermal analyses. J Manuf Process 23(1):47–53

Muthuramalingam T, Mohan B, Vignesh S (2018) Performance analysis of pulse generators on residual stress of machined silicon steel using EDM process. Silicon 10(5):1785–1792

Newton TR, Melkote SN, Watkins TR, Trejo RM, Reister L (2009) Investigation of the effect of process parameters on the formation and characteristics of recast layer in wire-EDM of Inconel 718. Mat Sci Eng A-Struct 513-514(1):208–215

Muthuramalingam T, Mohan B (2013) Influence of tool electrode properties on machinability in spark erosion machining. Mater Manuf Process 28(8):939–943

Muthuramalingam T, Mohan B, Rajadurai A, Prakash MAA (2013) Monitoring and fuzzy control approach for efficient electrical discharge machining process. Mater Manuf Process 29(3):281–286

Muthuramalingam T (2019) Measuring the influence of discharge energy on white layer thickness in the electrical discharge machining process. Measurement 131:694–700

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Muthuramalingam, T., Saravanakumar, D., Babu, L.G. et al. Experimental Investigation of White Layer Thickness on EDM Processed Silicon Steel Using ANFIS Approach. Silicon 12, 1905–1911 (2020). https://doi.org/10.1007/s12633-019-00287-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-019-00287-2