Abstract

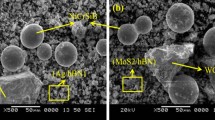

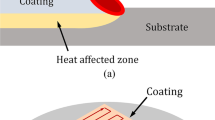

The aim of the present study is to improve the sliding wear resistance of pure titanium grade-2 substrate by developing CoMoCrSi (Tribaloy T400) cladding on it by using microwave hybrid heating technique. The developed cladding is characterized by microstructural features, phase analysis, measurement of microhardness by employing a scanning electron microscope (SEM), X-ray diffraction (XRD) and Vickers microhardness. The cladding and substrate are subjected to sliding wear test against alumina counterpart at elevated temperatures under dry conditions using a pin on disc tribometer. The test is performed by varying normal load and temperatures, whereas sliding speed is maintained constant. The developed clad shown partial melting of CoMoCrSi powders and obtained sound metallurgical bonding with the substrate. The high specific energy of microwave diluted the substrate atoms into cladding region which forms Cr3C2, Co3Ti, and TiC, phases confirmed by phase analysis. The cladding obtained better porosity and microhardness are 1.5 ± 0.2% μm and 760 ± 35 Hv respectively. The substrate exhibits low microhardness of 182 ± 25 Hv. The cladding exhibits 6 times of lower volume loss and 70.14% of less wear rate with respect to the substrate. The cladding experienced least coefficient of friction is 0.55 compared with the substrate. The worn surfaces of cladding and substrate are examined. The detailed mechanism of wear is discussed in this paper.

Similar content being viewed by others

References

Bemporad E, Sebastiani M, Casadei F, Carassiti F (2007) Modelling, production, and characterization of duplex coatings (HVOF and PVD) on Ti–6Al–4V substrate for specific mechanical applications. Surf Coat Technol 201:7652–7662

Bemporad E, Sebastiani M, Staia MH, Puchi Cabrera E (2008) Tribological studies on PVD/HVOF duplex coatings on Ti6Al4V substrate. Surf Coat Technol 203:566–571

Lin C-M, Yen S-H, Su C-Y (2016) Measurement and optimization of atmospheric plasma sprayed CoMoCrSi coatings parameters on Ti-6Al-4V substrates affecting microstructural and properties using hybrid abductor induction mechanism. Measurement 94:157–167

Khun NW, Tan AWY, Bi KJW, Liu E (2016) Effects of working gas on wear and corrosion resistance of cold sprayed Ti-6Al-4V coatings. Surf Coat Technol 302:1–12

Ramesh MR, Prakash S, Nath SK, Sapra PK, Venkataraman B (2010) Solid particle erosion of HVOF sprayed WC-Co/NiCrFeSiB coatings. Wear 269:197–205

Bolelli G, Lusvarghi L (2006) Heat treatment effects on the Tribological performance of HVOF sprayed Co-Mo-Cr-Si coatings. J Therm Spray Technol 15:802–810

Gao F, Liu R, Wu XJ (2010) Tribological behavior of T-401/tin–bronze composite coating deposited by HVOF on the bushing of planet journals. Wear 269:724–732

Cho JY, Zhang SH, Cho TY, Yoon JH, Joo YK, Hur SK (2009) The processing optimization and property evaluations of HVOF co-base alloy T800 coating. J Mater Sci 44:6348–6355

Utua ID, Marginean G (2017) Effect of electron beam remelting on the characteristics of HVOF sprayed Al2O3-TiO2 coatings deposited on titanium substrate. Colloids Surf A Physicochem Eng Asp 526:70–75

Sharma AK, Gupta D (2010) Method of cladding/coating of metallic and nonmetallic powders on metallic substrates by microwave irradiation, Indian patent 2010, application No. 527/Del

Gupta D, Sharma AK (2011) Investigation on sliding wear performance of WC10Co2Ni cladding developed through microwave irradiation. Wear 271:1642–1650

Hebbale AM, Srinath MS (2016) Microstructural investigation of Ni-based cladding developed on austenitic SS-304 through microwave irradiation. J Mater Res Technol 5:293–301

Gupta D, Sharma AK (2011) Development and microstructural characterization of microwave cladding on austenitic steel. Surf Coat Technol 205:5147–5155

Gupta D, Bhovi PM, Sharma AK, Dutta S (2012) Development and characterization of microwave composite cladding. J Manuf Process 14:243–249

Sharma AK, Gupta D (2012) On microstructure and flexural strength of metal–ceramic composite cladding developed through microwave heating. Appl Surf Sci 258:5583–5592

Zafar S, Sharma AK (2014) Development and characterizations of WC–12Comicrowave clad. Mater Charact 96:241–248

Srinath MS, Sharma AK, Kumar P (2011) A new approach to joining of bulk copper using microwave energy. Mater Des 32:2685–2694

Hebbale AM, Srinath MS (2017) Taguchi analysis on erosive wear behavior of cobalt based microwave cladding on stainless steel AISI-420. Measurement 99:98–107

Prasad CD, Joladarashi S, Ramesh MR, Srinath MS, Channabasappa BH (2018) Influence of microwave hybrid heating on the sliding wear behaviour of HVOF sprayed CoMoCrSi coating. Mater Res Express 5:086519

Prasad CD, Joladarashi S, Ramesh MR, Srinath MS, Channabasappa BH (2019) Microstructure and tribological behavior of flame sprayed and microwave fused CoMoCrSi/CoMoCrSi-Cr3C2 coatings. Mater Res Express 6(2019):026512

Li Y, Cui X, Jin G, Cai Z, Na T, Bingwen L, Gao Z (2017) Interfacial bonding properties between cobalt-based plasma cladding layer and substrate under tensile conditions. Mater Des 123:54–63

García A, Cadenas M, Fernandez MR, Noriega A (2013) Tribological effects of the geometrical properties of plasma spray coatings partially melted by a laser. Wear 305:1–7

Weng F, Yu H, Chen C, Liu J, Zhao L, Dai J, Zhao Z (2017) Effect of process parameters on the microstructure evolution and wear property of the laser cladding coatings on Ti-6Al-4V alloy. J Alloys Compd 692:989–996

Bolelli G, Cannillo V, Lusvarghi L, Ricco S (2006) Mechanical and tribological properties of electrolytic hard chrome and HVOF-sprayed coatings. Surf Coat Technol 200:2995–3009

Khor KA, Li H, Cheang P (2004) Significance of melt-fraction in HVOF sprayed hydroxyapatite particles, splats, and coatings. Biomaterials 25:1177–1186

Ortiz A, García A, Cadenas M, Fernandez MR, Cueto JM (2017) WC particles distribution model in the cross-section of laser cladded NiCrBSi + WC coatings, for different wt% WC. Surf Coat Technol 324:298–306. https://doi.org/10.1016/j.surfcoat.2017.05.086.

Huang SW, Samandi M, Brandt M (2004) Abrasive wear performance and microstructure of laser clad WC/Ni layers. Wear 256:1095–1105

Zhou S, Zeng X, Hu Q, Huang Y (2008) Analysis of crack behavior for Ni-based WC composite coatings by laser cladding and crack-free realization. Appl Surf Sci 255:1646–1653

Wood PD, Evans HE, Ponton CB (2010) Investigation into the wear behavior of Tribaloy 400C during rotation as an unlubricated bearing at 600 °C. Wear 269:763–769

Fernandez E, Cadenas M, Gonzalez R, Navas C, Fernandez R, de Damborene J (2005) Wear behaviour of laser clad NiCrBSi coating. Wear 259:870–875

Acknowledgments

Authors wish to thank Mechanical Engineering department NITK Surathkal for their encouragement and support to carryout wear experiments. This research work did not fund by any government or non-government sectors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prasad, C.D., Joladarashi, S., Ramesh, M.R. et al. Development and Sliding Wear Behavior of Co-Mo-Cr-Si Cladding through Microwave Heating. Silicon 11, 2975–2986 (2019). https://doi.org/10.1007/s12633-019-0084-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-019-0084-5