Abstract

In view of the EU’s circular economy strategy, there is a need to develop treatments that may allow to improve the management of industrial residues such as steel manufacturing slag, for example by producing secondary products that may be used for different applications. This work evaluates the performance of a combined carbonation and granulation treatment applied to basic oxygen furnace (BOF) steel slag with the aim of producing secondary aggregates and of storing CO2 in a solid and stable form. In order to improve the mechanical properties of the product, a solution of sodium silicate and sodium hydroxide was tested as binder instead of water in both the granulation and combined granulation–carbonation tests. The results showed that the granules produced using the alkali activator with or without CO2 addition, presented a mean size ranging from 1 to 5 mm and adequate mechanical properties for use in civil engineering applications. The maximum CO2 uptake attained was of 4% wt. for the alkali activated and carbonated granules after 60 min of treatment and 7 days curing. As for the leaching behaviour of the produced granules, an increase in the release of Cr and V was found for the product of the granulation–carbonation treatment with alkali activation. Instead, granulation with alkali activation or granulation with carbonation showed to decrease the release of Ba and Cr with regard to the untreated residues.

Similar content being viewed by others

References

Euroslag Statistics. http://www.euroslag.org/products/statistics/2012/ (2012). Accessed in March 2015

Bohmer, S., Moser, G., Neubauer, C., Peltoniemi, M., Schachermayer, E., Tesar, M., Walter, B., Winter, B.: Aggregate case study, Final Report (2008)

European Commission: Proposal for a Directive of The European Parliament and of the Council Amending Directive 2008/98/EC on waste Brussels, 2.12.2015 COM (2015) 595 final 2015/0275 (COD) (2015)

Mahieux, P.Y., Aubert, J.E., Escadeillas, G.: utilization of weathered basic oxygen furnace slag in the production of hydraulic road binders. Constr. Build. Mater. 23, 742–747 (2009)

Shen, D.-H., Wu, C.-M., Du, J.-C.: laboratory investigation of basic oxygen furnace slag for substitution of aggregate in porous asphalt mixture. Constr. Build. Mater. 23, 453–461 (2009)

Herrmann, I., Andreas, L., Diener, S., Lind, L.: Steel slag used in landfill cover liners: laboratory and field tests. Waste Manag. Res. 28, 1114–1121 (2010)

Italian Ministerial Decree 186/2006: Regolamento recante modifiche al decreto ministeriale 5 febbraio 1998 Individuazione dei rifiuti non pericolosi sottoposti alle procedure semplificate di recupero, ai sensi degli articoli 31 e 33 del decreto legislativo 5 febbraio 1997, n. 22. Gazzetta Ufficiale 19 maggio 2006, n. 115 (in italian) (2006)

Wang, G., Wang, Y., Gao, Z.: Use of steel slag as a granular material: volume expansion prediction and usability criteria. J. Hazard. Mater. 184, 555–560 (2010)

Baciocchi, R., Costa, G., Polettini, A., Pomi, R.: Effects of thin-film accelerated carbonation on steel slag leaching. J. Hazard. Mater. 286, 369–378 (2015)

Huijgen, W.J., Comans, R.N.: Carbonation of steel slag for CO2 sequestration: leaching of products and reaction mechanisms. Environ. Sci. Technol. 40, 2790–2796 (2006)

Litster, J., Ennis, B.: The Science and Engineering of Granulation Processes, Particle Technology Series. Dordrecht, Kluwer Academic Publishers (2004)

Iveson, S.M., Litster, J.D., Hapgood, K., Ennis, B.J.: Nucleation, growth and breakage phenomena in agitated wet granulation processes: a review. Powder Technol. 117, 3–39 (2001)

Adetayo, A.A., Litster, J.D., Desai, M.: The effect of process parameters on drum granulation of fertilizers with broad size distributors. Chem. Eng. Sci. 48, 3951–3961 (1993)

Tardos, G.I., Khan, M.I., Mort, P.R.: Critical parameters and limiting conditions in binder granulation of fine powders. Powder Technol. 94, 245–258 (1997)

Medici, F., Piga, L., Rinaldi, G.: Behaviour of polyaminophenolic additives in the granulation of lime and fly-ash. Waste Manag. 20, 491–498 (2000)

Baykal, G., Döven, A.G.: Utilization of fly ash by pelletization process; theory, application areas and research results. Resour. Conserv. Recyl. 30(1), 59–77 (2000)

Scanferla, P., Ferrari, G., Pellay, R., Volpi Ghirardini, A., Zanetto, G., Libralato, G.: An innovative stabilization/solidification treatment for contaminated soil remediation: demonstration project results. J. Soils Sedim. 9, 229–236 (2009)

Cioffi, R., Colangelo, F., Montagnaro, F., Santoro, L.: Manufacture of artificial aggregate using MSWI bottom ash. Waste Manag. 31, 281–288 (2011)

Bobicki, E.R., Liu, Q., Xu, Z., Zeng, H.: Carbon capture and storage using alkaline industrial wastes. Prog. Energy Combust. 38, 302–320 (2012)

Lange, L.C., Hills, C.D., Poole, A.B.: The influence of mix parameters and binder choice on the carbonation of cement solidified wastes. Waste Manag. 16, 749–756 (1996)

Seifritz, W.: CO2 disposal by means of silicates. Nature 345, 486 (1990)

Lackner, K.S., Wendt, C.H., Butt, D., Joyce Jr., E.L., Sharp, D.H.: Carbon dioxide disposal in carbonate minerals. Energy 20, 1153–1170 (1995)

Pan, S.Y., Chang, E.E., Chiang, P.C.: CO2 capture by accelerated carbonation of alkaline wastes: a review on its principles and applications. Aerosol Air Qual. Res. 12, 770–791 (2012)

Baciocchi, R., Costa, G., Zingaretti, D., Baciocchi, R.: Accelerated carbonation processes for carbon dioxide capture, storage and utilization. In: Bhanage, B.M., Arai, M. (eds.) Transformation and Utilization of Carbon Dioxide, Green Chemistry and Sustainable Technology, pp. 263–299. Springer, Berlin (2014)

Johnson, D.C., Macleod, C.L., Carey, P.J., Hills, C.D.: Solidification of stainless steel slag by accelerated carbonation. Environ. Technol. 24, 671–678 (2003)

Baciocchi, R., Costa, G., Di Bartolomeo, E., Polettini, A., Pomi, R.: Carbonation of stainless steel slag as a process for CO2 storage and slag valorization. Waste Biomass Valor. 1, 467–477 (2010)

Santos, R.M., Van Bouwel, J., Vandevelde, E., Mertens, G., Elsen, J., Van Gerven, T.: Accelerated mineral carbonation of stainless steel slags for CO2 storage and waste valorization: effect of process parameters on geochemical properties. Int. J. Greenh. Gas Control 17, 32–45 (2013)

Baciocchi, R., Costa, G., Di Gianfilippo, M., Polettini, A., Pomi, R., Stramazzo, A.: Thin-film versus slurry-phase carbonation of steel slag: CO2 uptake and effects on mineralogy. J. Hazard. Mater. 283, 302–313 (2015)

Gunning, P.J., Hills, C.D., Carey, P.J.: Production of lightweight aggregate from industrial waste and carbon dioxide. Waste Manag. 29, 2722–2728 (2009)

Morone, M., Costa, G., Polettini, A., Pomi, R., Baciocchi, R.: Valorization of steel slag by a combined carbonation and granulation treatment. Miner. Eng. 59, 82–90 (2014)

British Standard 812 Testing aggregates—part 110: Methods for determination of aggregate crushing value (ACV). ISBN 0 580 18825 6 (1990)

Pacheco-Torgal, F., Castro-Gomes, J., Jalali, S.: Alkali-activated binders: a review. Part 2. About materials and binders manufacture. Constr. Build. Mater. 22, 1315–1322 (2008)

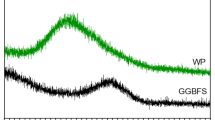

Song, S., Sohn, D., Jennings, H.M., Mason, T.O.: Hydration of alkali-activated ground granulated blast furnace slag. J. Mater. Sci. 35, 249–257 (2000)

Rashad, Alaa M.: a comprehensive overview about the influence of different additives on the properties of alkali-activated slag–a guide for civil engineer. Constr. Build. Mater. 47, 29–55 (2013)

Kriskova, L., Pontikes, Y., Zhang, F., Cizer, Ö., Jones, P.T., Van Balen, K., Blanpain, B.: Influence of mechanical and chemical activation on the hydraulic properties of gamma dicalcium silicate. Cem. Concr. Res. 55, 59–68 (2014)

Salman, M., Cizer, Ö., Pontikes, Y., Vandewalle, L., Blanpain, B., Van Balen, K.: Effect of curing temperatures on the alkali activation of crystalline continuous casting stainless steel slag. Constr. Build. Mater. 71, 308–316 (2014)

Morone M., Cizer Ö., Costa G., Baciocchi R.: Alkali activation and CO2 curing for BOF steel slag valorization. Cem. Concr. Compos. (Submitted)

Iveson, S.M., Litster, J.D., Ennis, B.J.: Fundamental studies of granule consolidation part 1: effects of bonder content and binder viscosity. Powder Technol. 88, 15–20 (1996)

Wauters, P.A.L., van de Water, R., Litster, J.D., Meesters, G.M.H., Scarlett, B.: Growth and compaction behaviour of copper concentrate granules in a rotating drum. Powder Technol. 124, 230–237 (2002)

Liu, L.X., Litster, J.D., Iveson, S.M., Ennis, B.J.: Coalescence of deformable granules in wet granulation processes. AIChE J. 46, 529–539 (2000)

Baciocchi, R., Costa, G., Polettini, A., Pomi, R.: Influence of particle size on the carbonation of stainless steel slag for CO2 storage. Energy Procedia 1, 4859–4866 (2009)

van Zomeren, A., Van der Laan, S.R., Kobesen, H., Huijgen, W.J., Comans, R.N.: Changes in mineralogical and leaching properties of converter steel slag resulting from accelerated carbonation at low CO2 pressure. Waste Manag. 31, 2236–2244 (2011)

Acknowledgements

This work was financially supported by the Italian Ministry of Economic Development within the National Programme on Electric System Research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Morone, M., Costa, G., Georgakopoulos, E. et al. Granulation–Carbonation Treatment of Alkali Activated Steel Slag for Secondary Aggregates Production. Waste Biomass Valor 8, 1381–1391 (2017). https://doi.org/10.1007/s12649-016-9781-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9781-0