Abstract

Purpose

The present study aims to recover value-added products from fresh pineapple processing wastes in an integrated biorefinery.

Methods

Bromelain, a therapeutic protease, was extracted from pineapple by-products via an aqueous, low-temperature process. Bromelain-free biomass was rich in insoluble fibre and was further fractionated into hemicellulose, cellulose and lignin.

Results

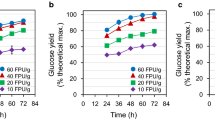

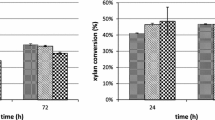

The highest content of active bromelain was obtained from pineapple core waste of the different varieties namely, Smooth Cayenne (~ 1.9 ± 0.05 CDU/mg), Giant Kew (1.6 ± 0.05 CDU/mg) and MD2 (1.5 ± 0.1 CDU/mg). The activity of extracted bromelain was close to commercial stem bromelain (2.2 ± 0.1 CDU/mg, % purity of 95–96%). The fractionation of fibrous residue (97.2 ± 0.5 g/100 g of dry mass) was optimised, and maximum yield of hemicellulose (97.5 ± 0.2%) was obtained with 5% (w/v) alkali at the end of 1.5 h. The hemicellulose and cellulose-rich residues were further valorised into xylooligosaccharides (26.1 ± 0.4 g/100 g of hemicellulose) and glucose (85.3 ± 1.7 g/100 g of cellulose-rich residue), respectively. From one ton of fresh pineapple processing waste, ~ 1 kg bromelain, ~ 24 kg xylooligosaccharides, ~ 88 kg glucose and ~ 68 kg residual hemicellulose could be obtained.

Conclusion

The proposed biorefinery concept not only addresses the environmental issues but also creates an opportunity to generate wealth in the form of products required for food and pharmaceutical industries from processing waste. As demand for more natural products is rising and consumers choice are prompted by healthy foods, conversion of pineapple waste into above mentioned valuable products creates a niche in food and therapeutics industry.

Graphic Abstract

Schematic for extraction of bromelain coupled with co-production of xylooligosaccharides and glucose from pineapple waste.

Similar content being viewed by others

References

Banerjee, S., Ranganathan, V., Patti, A., Arora, A.: Valorisation of pineapple wastes for food and therapeutic applications. Trends Food Sci. Technol. 82, 60–70 (2018). https://doi.org/10.1016/j.tifs.2018.09.024

Patsalou, M., Chrysargyris, A., Tzortzakis, N., Koutinas, M.: A biorefinery for conversion of citrus peel waste into essential oils, pectin, fertilizer and succinic acid via different fermentation strategies. Waste Manag. 113, 469–477 (2020). https://doi.org/10.1016/j.wasman.2020.06.020

Goula, A.M., Lazarides, H.N.: Integrated processes can turn industrial food waste into valuable food by-products and/or ingredients: the cases of olive mill and pomegranate wastes. J. Food Eng. 167, 45–50 (2015)

Garcia-Garcia, G., Stone, J., Rahimifard, S.: Opportunities for waste valorisation in the food industry—a case study with four UK food manufacturers. J. Clean. Prod. 211, 1339–1356 (2019). https://doi.org/10.1016/j.jclepro.2018.11.269

del Pozo, C., Bartrolí, J., Alier, S., Puy, N., Fàbregas, E.: Production of antioxidants and other value-added compounds from coffee silverskin via pyrolysis under a biorefinery approach. Waste Manag. 109, 19–27 (2020). https://doi.org/10.1016/j.wasman.2020.04.044

Karmee, S.K.: A spent coffee grounds based biorefinery for the production of biofuels, biopolymers, antioxidants and biocomposites. Waste Manag. 72, 240–254 (2018). https://doi.org/10.1016/j.wasman.2017.10.042

Venkata Mohan, S., Nikhil, G.N., Chiranjeevi, P., Nagendranatha Reddy, C., Rohit, M.V., Kumar, A.N., et al.: Waste biorefinery models towards sustainable circular bioeconomy: critical review and future perspectives. Bioresour. Technol. 215, 2–12 (2016). https://doi.org/10.1016/j.biortech.2016.03.130

Lokesh, K., Ladu, L., Summerton, L.: Bridging the gaps for a “circular” bioeconomy: selection criteria, bio-based value chain and stakeholder mapping. Sustain 10, 1695 (2018). https://doi.org/10.3390/su10061695

Hennig, C., Brosowski, A., Majer, S.: Sustainable feedstock potential—a limitation for the bio-based economy? J. Clean. Prod. 123, 200–202 (2016). https://doi.org/10.1016/j.jclepro.2015.06.130

Pfaltzgraff, L.A., De Bruyn, M., Cooper, E.C., Budarin, V., Clark, J.H.: Food waste biomass: a resource for high-value chemicals. Green Chem. 15, 307–314 (2013). https://doi.org/10.1039/c2gc36978h

Roda, A., De Faveri, D.M., Giacosa, S., Dordori, R., Lambri, M.: Effect of pre-treatments on the saccharification of pineapple waste as a potential source for vinegar production. J. Clean. Prod. 112, 4477–4484 (2016)

Lamine, M., Gargouri, M., Rahali, F.Z., Mliki, A.: Recovering and characterizing phenolic compounds from citrus by-product: a way towards agriculture of subsistence and sustainable bioeconomy. Waste Biomass Valoriz (2020). https://doi.org/10.1007/s12649-020-01306-9

Goula, A.M., Papatheodorou, A., Karasavva, S., Kaderides, K.: Ultrasound-assisted aqueous enzymatic extraction of oil from pomegranate seeds. Waste Biomass Valoriz (2018). https://doi.org/10.1007/s12649-016-9740-9

Talekar, S., Patti, A.F., Vijayraghavan, R., Arora, A.: An integrated green biorefinery approach towards simultaneous recovery of pectin and polyphenols coupled with bioethanol production from waste pomegranate peels. Bioresour. Technol. 266, 322–334 (2018). https://doi.org/10.1016/j.biortech.2018.06.072

Banerjee, J., Singh, R., Vijayaraghavan, R., MacFarlane, D., Patti, A.F., Arora, A.: A hydrocolloid based biorefinery approach to the valorisation of mango peel waste. Food Hydrocoll. 77, 142–151 (2018). https://doi.org/10.1016/j.foodhyd.2017.09.029

Boukroufa, M., Boutekedjiret, C., Petigny, L., Rakotomanomana, N., Chemat, F.: Bio-refinery of orange peels waste: a new concept based on integrated green and solvent free extraction processes using ultrasound and microwave techniques to obtain essential oil, polyphenols and pectin. Ultrason. Sonochem. 24, 72–79 (2015). https://doi.org/10.1016/j.ultsonch.2014.11.015

Dávila, J.A., Rosenberg, M., Castro, E., Cardona, C.A.: A model biorefinery for avocado (Persea americana mill.) processing. Bioresour. Technol. 243, 17–29 (2017). https://doi.org/10.1016/j.biortech.2017.06.063

FAO: Major Tropical Fruits Market Review 2018. FAO, Rome (2019)

APEDA.: Indian production of pineapple. National Horticulture Board (2018). http://agriexchange.apeda.gov.in/IndiaProduction/India_Productions.aspx?cat=fruit&hscode=1056. Accessed March 3, 2020

HortInnovation.: Australian Horticulture Satistics Handbook—Fruits (2018). https://www.horticulture.com.au/growers/help-your-business-grow/research-reports-publications-fact-sheets-and-more/HA18002/. Accessed March 3, 2020

Abdullah, M.B., Mat, H.: Characterisation of solid and liquid pineapple waste. Reaktor 12, 48–52 (2008)

Ketnawa, S., Chaiwut, P., Rawdkuen, S.: Pineapple wastes: a potential source for bromelain extraction. Food Bioprod. Process 90, 385–391 (2012). https://doi.org/10.1016/j.fbp.2011.12.006

Banerjee, S., Patti, A.F., Ranganathan, V., Arora, A.: Hemicellulose based biorefinery from pineapple peel waste: xylan extraction and its conversion into xylooligosaccharides. Food Bioprod. Process 117, 38–50 (2019). https://doi.org/10.1016/j.fbp.2019.06.012

Seguí, L., Fito Maupoey, P.: An integrated approach for pineapple waste valorisation. Bioethanol production and bromelain extraction from pineapple residues. J. Clean. Prod. 172, 1224–1231 (2018). https://doi.org/10.1016/j.jclepro.2017.10.284

Sepúlveda, L., Romaní, A., Aguilar, C.N., Teixeira, J.: Valorization of pineapple waste for the extraction of bioactive compounds and glycosides using autohydrolysis. Innov. Food Sci. Emerg. Technol. 47, 38–45 (2018). https://doi.org/10.1016/j.ifset.2018.01.012

Kongsuwan, A., Suthiluk, P., Theppakorn, T., Srilaong, P., Setha, V.: Bioactive compounds and antioxidant capacities of phulae and nanglae pineapple. Asian J. Food Agro-Ind. 2, S44–S50 (2009)

Roda, A., Lambri, M.: Food uses of pineapple waste and by-products: a review. Int. J. Food Sci. Technol. 54, 1009–1017 (2019). https://doi.org/10.1111/ijfs.14128

Campos, D.A., Ribeiro, T.B., Teixeira, J.A., Pastrana, L., Pintado, M.M.: Integral valorization of pineapple (Ananas comosus L.) by-products through a green chemistry approach towards added value ingredients.Foods (2020). https://doi.org/10.3390/foods9010060

Aruna, T.E.: Production of value-added product from pineapple peels using solid state fermentation. Innov. Food Sci. Emerg. Technol. (2019). https://doi.org/10.1016/j.ifset.2019.102193

Casabar, J.T., Unpaprom, Y., Ramaraj, R.: Fermentation of pineapple fruit peel wastes for bioethanol production. Biomass Convers Biorefinery 9, 761–765 (2019). https://doi.org/10.1007/s13399-019-00436-y

de Ramos, R.M.Q., Siacor, F.D.C., Taboada, E.B.: Effect of maltodextrin content and inlet temperature on the powder qualities of spray-dried pineapple (Ananas comosus) waste extract. Waste Biomass Valoriz. 11, 3247–3255 (2020). https://doi.org/10.1007/s12649-019-00651-8

Teixeira, W.F.A., Batista, R.D., do Amaral Santos, C.C.A., Júnior, A.C.F., Terrasan, C.R.F., de Santana, M.W.P.R., et al.: Minimal enzymes cocktail development by filamentous fungi consortia in solid-state cultivation and valorization of pineapple crown waste by enzymatic saccharification. Waste Biomass Valoriz. 12, 2521–2539 (2021). https://doi.org/10.1007/s12649-020-01199-8

Banerjee, S., Ranganathan, V., Arora, A., Patti, A.F.: Green approach towards hydrolysing wheat gluten using waste ingredients from pineapple processing industries. Int. J. Food Sci. Technol. (2020). https://doi.org/10.1111/ijfs.14796

Murachi, T.: [39] Bromelain enzymes. Methods Enzymol 45, 475–485 (1976). https://doi.org/10.1016/S0076-6879(76)45042-5

AOAC.: Determination of moisture, ash, protein and fat. Off method. Anal. Assoc. Anal. Chem. (2005)

Lee, S.C., Prosky, L., DeVries, J.W.: Determination of total, soluble and insoluble dietary fiber in foods-enzymatic-gravimetric method, MES-tris buffer: collaborative study. J. AOAC Int. 75, 395–416 (1992)

Martínez, R., Torres, P., Meneses, M.A., Figueroa, J.G., Pérez-Álvarez, J.A., Viuda-Martos, M.: Chemical, technological and in vitro antioxidant properties of mango, guava, pineapple and passion fruit dietary fibre concentrate. Food Chem. 135, 1520–1526 (2012). https://doi.org/10.1016/j.foodchem.2012.05.057

Van Soest, P.J., Robertson, J.B., Lewis, B.A.: Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 74, 3583–3597 (1991). https://doi.org/10.3168/jds.S0022-0302(91)78551-2

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., et al.: Determination of structural carbohydrates and lignin in Biomass. Laboratory Analytical Procedures NREL/TP-510-42618 (2012)

Sluiter, A., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D.: Determination of extractives in biomass: laboratory analytical procedure (LAP); Issue Date 7/17/2005 (2008).

Khedkar, M.A., Nimbalkar, P.R., Kamble, S.P., Gaikwad, S.G., Chavan, P.V., Bankar, S.B.: Process intensification strategies for enhanced holocellulose solubilization: beneficiation of pineapple peel waste for cleaner butanol production. J. Clean. Prod. 199, 937–947 (2018). https://doi.org/10.1016/j.jclepro.2018.07.205

Harde, S.M., Jadhav, S.B., Bankar, S.B., Ojamo, H., Granström, T., Singhal, R.S., et al.: Acetone-butanol-ethanol (ABE) fermentation using the root hydrolysate after extraction of forskolin from Coleus forskohlii. Renew. Energy 86, 594–601 (2016). https://doi.org/10.1016/j.renene.2015.08.042

Martins, B.C., Rescolino, R., Coelho, D.F., Zanchetta, B., Tambourgi, E.B., Silveira, E.: Characterization of bromelain from ananas comosus agroindustrial residues purified by ethanol factional precipitation. Chem. Eng. Trans. 37, 781–786 (2014). https://doi.org/10.3303/CET1437131

Soares, P.A.G., Vaz, A.F.M., Correia, M.T.S., Pessoa, A., Carneiro-Da-Cunha, M.G.: Purification of bromelain from pineapple wastes by ethanol precipitation. Sep. Purif. Technol. 98, 389–395 (2012). https://doi.org/10.1016/j.seppur.2012.06.042

Banerjee, S., Arora, A., Vijayaraghavan, R., Patti, A.F.: Extraction and crosslinking of bromelain aggregates for improved stability and reusability from pineapple processing waste. Int. J. Biol. Macromol. 158, 318–326 (2020). https://doi.org/10.1016/j.ijbiomac.2020.04.220

Abreu, D.C.A., De Figueiredo, K.C.S.: Bromelain separation and purification processes from pineapple extract. Brazilian J. Chem. Eng. 36, 1029–1039 (2019). https://doi.org/10.1590/0104-6632.20190362s20180417

Hu, H., Zhao, Q.: Optimization extraction and functional properties of soluble dietary fiber from pineapple pomace obtained by shear homogenization-assisted extraction. RSC Adv. 8, 41117–41130 (2018). https://doi.org/10.1039/C8RA06928J

Chareonthaikij, P., Uan-On, T., Prinyawiwatkul, W.: Effects of pineapple pomace fibre on physicochemical properties of composite flour and dough, and consumer acceptance of fibre-enriched wheat bread. Int. J. Food Sci. Technol. 51, 1120–1129 (2016). https://doi.org/10.1111/ijfs.13072

Devi, L.K., Karoulia, S., Chaudhary, N.: Preparation of high dietary fibre cookies from pineapple (Ananas comosus) pomace. Int. J. Sci. Res. 5, 1368–1372 (2016). https://doi.org/10.21275/v5i5.nov163610

Selani, M.M., Brazaca, S.G.C., Dos Santos Dias, C.T., Ratnayake, W.S., Flores, R.A., Bianchini, A.: Characterisation and potential application of pineapple pomace in an extruded product for fibre enhancement. Food Chem. 163, 23–30 (2014). https://doi.org/10.1016/j.foodchem.2014.04.076

Prakongpan, T., Nitithamyong, A., Luangpituksa, P.: Extraction and application of dietary fiber and cellulose from pineapple cores. J. Food Sci. 67, 1308–1313 (2002). https://doi.org/10.1111/j.1365-2621.2002.tb10279.x

Figuerola, F., Hurtado, M.L., Estévez, A.M., Chiffelle, I., Asenjo, F.: Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chem. 91, 395–401 (2005). https://doi.org/10.1016/j.foodchem.2004.04.036

Raghavendra, S.N., Ramachandra Swamy, S.R., Rastogi, N.K., Raghavarao, K.S.M.S., Kumar, S., Tharanathan, R.N.: Grinding characteristics and hydration properties of coconut residue: a source of dietary fiber. J. Food Eng. 72, 281–286 (2006). https://doi.org/10.1016/j.jfoodeng.2004.12.008

Aachary, A.A., Prapulla, S.G.: Value addition to corncob: production and characterization of xylooligosaccharides from alkali pretreated lignin-saccharide complex using Aspergillus oryzae MTCC 5154. Bioresour. Technol. 100, 991–995 (2009). https://doi.org/10.1016/j.biortech.2008.06.050

Takkellapati, S., Li, T., Gonzalez, M.A.: An overview of biorefinery-derived platform chemicals from a cellulose and hemicellulose biorefinery. Clean Technol. Environ. Policy 20, 1615–1630 (2018). https://doi.org/10.1007/s10098-018-1568-5

Xin, F., Chen, T., Jiang, Y., Dong, W., Zhang, W., Zhang, M., et al.: Strategies for improved isopropanol-butanol production by a clostridium strain from glucose and hemicellulose through consolidated bioprocessing. Biotechnol. Biofuels (2017). https://doi.org/10.1186/s13068-017-0805-1

Gravitis, J., Vedernikov, N., Zandersons, J., Kokorevics, A.: Furfural and levoglucosan production from deciduous wood and agricultural wastes. ACS Symp. Ser. 784, 110–122 (2001). https://doi.org/10.1021/bk-2001-0784.ch009

Machado, G., Leon, S., Santos, F., Lourega, R., Dullius, J., Mollmann, M.E., et al.: Literature review on furfural production from lignocellulosic biomass. Nat. Resour. 07, 115–129 (2016). https://doi.org/10.4236/nr.2016.73012

Verma, S., Baig, R.B.N., Nadagouda, M.N., Len, C., Varma, R.S.: Sustainable pathway to furanics from biomass: via heterogeneous organo-catalysis. Green Chem. 19, 164–168 (2017). https://doi.org/10.1039/c6gc02551j

Yan, K., Wu, G., Lafleur, T., Jarvis, C.: Production, properties and catalytic hydrogenation of furfural to fuel additives and value-added chemicals. Renew. Sustain. Energy Rev. 38, 663–676 (2014). https://doi.org/10.1016/j.rser.2014.07.003

Mariscal, R., Maireles-Torres, P., Ojeda, M., Sádaba, I., López, G.M.: Furfural: a renewable and versatile platform molecule for the synthesis of chemicals and fuels. Energy Environ Sci 9, 1144–1189 (2016). https://doi.org/10.1039/c5ee02666k

Rafiqul, I.S.M., Sakinah, A.M.M.: Processes for the production of Xylitol-A review. Food Rev Int 29, 127–156 (2013). https://doi.org/10.1080/87559129.2012.714434

Chandel, A.K., Antunes, F.A.F., Terán-Hilares, R., Cota, J., Ellilä, S., Silveira, M.H.L., et al.: Bioconversion of hemicellulose into ethanol and value-added products: commercialization, trends, and future opportunities. Commercialization, trends, and future opportunities. Adv. Sugarcane Biorefinery Technol. Commer. Policy Issues Paradig. Shift Bioethanol. By-Products (2018). https://doi.org/10.1016/B978-0-12-804534-3.00005-7

Avanthi, A., Kumar, S., Sherpa, K.C., Banerjee, R.: Bioconversion of hemicelluloses of lignocellulosic biomass to ethanol: an attempt to utilize pentose sugars. Biofuels 8, 431–444 (2017). https://doi.org/10.1080/17597269.2016.1249738

Njoku, S., Iversen, J., Uellendahl, H., Ahring, B.: Production of ethanol from hemicellulose fraction of cocksfoot grass using pichia stipitis. Sustain Chem Process 1, 13 (2013). https://doi.org/10.1186/2043-7129-1-13

Chandel, A.K., Chandrasekhar, G., Radhika, K., Ravinder, R., Ravindra, P.: Bioconversion of pentose sugars into ethanol: a review and future directions. Biotechnol Mol Biol Rev 6, 8–20 (2011)

Singh, R.D., Bhuyan, K., Banerjee, J., Muir, J., Arora, A.: Hydrothermal and microwave assisted alkali pretreatment for fractionation of arecanut husk. Ind Crops Prod 102, 65–74 (2017). https://doi.org/10.1016/j.indcrop.2017.03.017

Acknowledgements

The authors would like to thank the IITB-Monash Research Academy to provide financial support (IMURA0453) to SB for her doctoral study. The authors acknowledge the use of the facilities and the assistance of Dr. Xiya Fang at the Monash Centre for Electron Microscopy.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Banerjee, S., Vijayaraghavan, R., Patti, A.F. et al. Integrated Biorefinery Strategy for Valorization of Pineapple Processing Waste into High-Value Products. Waste Biomass Valor 13, 631–643 (2022). https://doi.org/10.1007/s12649-021-01542-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01542-7