Abstract

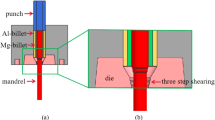

Spin-bonding is a novel tube cladding method for fabrication of bilayer tubes based on flow-forming process. The bimetal Al/St tubular components have extensive application in different industries. In this paper, an Al/St bimetal tube was successfully produced at different thickness reductions from 35 to 65% and mechanical and metallurgical aspects of the joint were investigated. Peeling tests were done to investigate the strength of the bond. The results showed that an increase in the thickness reduction led to a significant increase in the bond strength. Besides, the bonding mechanism between Al as inner tube to St as an outer one resulting from spin-bonding process was investigated. The results showed that an excellent bonding of Al and St tubes could be achieved from this process. The results showed that the bonding process consisted of three stages. First, removal of surface layers resulting in contact between the virgin metals of two bond surfaces and then an unstable bond was formed that stabilized as deformation proceeded. Finally the bond strengthening occurred. The SEM micrographs of the peeled surfaces showed that removing surface films in aluminum and steel in the first stage was based on different mechanisms. Also, SEM back-scatter images of bond interface showed that no intermetallic phases were formed.

Similar content being viewed by others

References

Mohebbi M S, and Akbarzadeh A, Int. J. Adv. Manuf. Technol. 54 (2011) 1043.

Li L, Nagai K, and Yin F X, Sci. Technol. Adv. Mater. 9 (2008).

Chen L, Yang Z, Jha B, Xia G, and Stevenson J W, J. Power Sources 152 (2005) 40.

Baghaei M, and Faraji G, J. Adv. Mater. Process. 4 (2016) 21.

Bay N, Bjerregaard H, Petersen S B, and Dos Santos C H, J. Mater. Process. Technol. 45(1–4) (1994) 1.

Kim S H, Kim H W, Euh K, Kang J H, and Cho J H, Mater. Des. 35 (2012) 290.

Li X, Zu G, and Deng Q, in Light Metals 2011. Wiley, New York (2011), p 611.

Faraji G, and Kim H, Mater. Sci. Technol. 33 (2017) 905–923.

Buchner M, Buchmayr B, Bichler C, and Riemelmoser F, AIP Conf. Proc. 907 (2007) 264.

Manesh H D, and Taheri A K, Mater. Des. 24 (2003) 617.

Cline C L, Weld. J. 45 (1966) 481-s. ISSN 0043-2296 CODEN WEJUA3.

Hosseini S A, Hosseini M, and Manesh H D, Mater. Des. 32 (2011) 76.

Bay N, Clemensen C, Juelstorp O, and Wanheim T, CIRP Ann. Manuf. Technol. 34 (1985) 221.

Pan D, Gao K, and Yu J, Mater. Sci. Technol. 5 (1989) 934.

Jamaati R, and Toroghinejad M R, Mater. Sci. Eng. A 527 (2010) 2320.

Mohamed H A, and Washburn J, Weld. J. (Miami); (United States) (1975) p. Medium: X; Size: Pages: vp.

Buchner M, Buchner B, Buchmayr B, Kilian H, and Riemelmoser F, Int. J. Mater. Form. 1 (2008) 1279.

Jindal V, and Srivastava V C, J. Mater. Process. Technol. 195 (2008) 88.

Kang H G, Kim J K, Huh M Y, and Engler O, Mater. Sci. Eng. A 452–453 (2007) 347.

Kawase H, Makimoto M, Takagi K, Ishida Y, and Tanaka T, Trans. Iron Steel Inst. Jpn. 23 (1983) 628.

Manesh H D, and Shahabi H S, J. Alloys Compd. 476 (2009) 292.

Manesh H D, and Taheri A K, J. Alloys Compd. 361 (2003) 138.

Manesh H D, and Taheri A K, Mater. Sci. Technol. 20 (2004) 1064.

Movahedi M, Kokabi A H, and Seyed Reihani S M, Mater. Des. 32 (2011) 3143.

Nezhad M S A, and Ardakani A H, Mater. Des. 30 (2009) 1103.

Chitkara N R, and Aleem A, Int. J. Mech. Sci. 43 (2001) 2857.

Khosravifard A, and Ebrahimi R, Mater. Des. 31 (2010) 493.

Chen Z, Ikeda K, Murakami T, Takeda T, and Xie J X, J. Mater. Process. Technol. 137 (2003) 10.

Sun X J, Tao J, and Guo X Z, Trans. Nonferr. Met. Soc. China 21 (2011) 2175.

Bhanumurthy K, Mater. Sci. Technol. 22 (2006) 321.

Sponseller D L, Timmons G A, and Bakker W T, J. Mater. Eng. Perform. 7 (1998) 227.

Wang X S, Li P N, and Wang R Z, Int. J. Mach. Tools Manuf. 45 (2005) 373.

Mohebbi M S, and Akbarzadeh A, J. Mater. Process. Technol. 210 (2010) 510.

Zhan Z, He Y, Wang D, and Gao W, Surf. Coat. Technol. 201 (2006) 2684.

Reshadi F, Faraji G, Aghdamifar S, Yavari P, and Mashhadi M M, Mater. Sci. Technol. 31 (2015) 1879.

Faraji G, Babaei A, Mashhadi M M, and Abrinia K, Mater. Lett. 77 (2012) 82.

Afrasiab M, Faraji G, Tavakkoli V, Mashhadi M M, and Dehghani K, Trans. Indian Inst. Met. 68 (2015) 873.

Lapovok R, Ng H P, Tomus D, and Estrin Y, Scr. Mater. 66 (2012) 1081.

Movahedi M, Kokabi A, and Reihani S S, Mater. Des. 32 (2011) 3143.

Manesh H D, and Shahabi H S, J. Alloys Compd. 476 (2009) 292.

Jamaati R, and Toroghinejad M R, J. Mater. Eng. Perform. 20 (2011) 191.

Chawla, S.L., Materials selection for corrosion control. Vol. 1. ASM international (1993)

Gur M, and Tirosh J, J. Eng. Ind. 104 (1982) 17.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Samandari, M., Abrinia, K., Akbarzadeh, A. et al. Properties and Mechanism of Al/St Bimetal Tube Bonding Produced by Cold Spin-Bonding (CSB) Process. Trans Indian Inst Met 70, 2673–2682 (2017). https://doi.org/10.1007/s12666-017-1128-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1128-4