Abstract

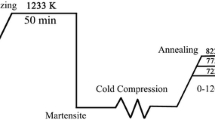

In the present study, low-carbon steel was first evenly cryorolled by 50% reduction at liquid nitrogen temperature (LNT) and then annealed at 400–550 °C for 1800 s. A transmission electron microscope was employed to analyze the microstructures and the tangled dislocations in the processed steel. The presence of Fe3C particles in the steel was confirmed by X-ray diffraction method, and the mechanical properties were measured by an electronic universal tensile machine. It was found that cryorolling at LNT significantly improved the potentials of refined ferrite grains. Grain refinement at LNT occurred due to the suppression of dynamic recovery during cryorolling, thus resulting in high defect density and abundant nucleation sites for ferrite grains. An average ferrite grain size of 133 nm was observed in the specimen annealed at 450 °C for 1800 s, and its strength increased to 970.2 MPa with a reasonable ductility of 12.34%. The work extended the cryorolling from alloys and austenitic stainless steels to the low-carbon steels and provided a technical support for the fabrication of ultrafine grained low-carbon steel.

Similar content being viewed by others

References

Lu K, Science 345 (2014)1455.

Wang B F, Sun J Y, Zou J D, Vincent S, and Li J, J Cent South Univ 22 (2015) 3698.

Matsybara K, Miyahara Y, Horita Z, and Langdon T G, Acta Mater 51 (2003) 3073.

Shin D H, Kim B C, Park K, and Kim Y S, Acta Mater 48 (2000) 2247.

Tsuji N, Shiotsuki K, and Saito Y, Mater Trans JIM 40 (1999) 765.

Tsuji N, Ueji R, and Saito Y, Mater Jpn 39 (2000) 961. (in Japanese)

Saito Y, Utsunomiya H, Tsuji N, and Sakai T, Acta Mater 47 (1999) 579.

Belyakov A, Sakika Y, Hara T, Kimura Y, and Tsuzaki K, Metall Mater Trans A 34 (2003) 131.

Takaki S, Kawasaki K, and Kimura Y, in Ultrafine grained materials, (eds) Mishra R S, The Minerals, Metals & Materials Society (TMS), Warrendale (2000).

Valiev R Z, Ivanisenko Y, Rauch E F, and Baudelet B, J Mater Sci 47 (2012) 7789.

Horita Z, Smith D, Furukwa M, Nnemoto M, Valiev R Z, and Langdon T G, J Mater Res 11 (1996) 1880.

Tsuji N, Ueji R, Minamino Y, and Saito Y, Scripta Mater 46 (2002) 305.

Bao Y Z, Adachi Y, Toomine Y, Xu P G, Suzuki T, and Tomota Y, Scripta Mater 53 (2005) 1471.

Ueji R, Tsuji N, Minamino Y, and Koizumi Y, Acta Mater 50 (2002) 4177.

Ashrafi H, and Najafizadeh A, Trans Indian Inst Met 8 (2016) 1467.

Shanmugasundaram T, Murty B S, and Sarma V S, Scripta Mater 54 (2006) 2013.

Panigrahi S K, and Jayaganthan R, Metall Mater Trans A 41A (2010) 2675.

Rao P N, Singh D, and Jayaganthan R, Mater Design 56 (2014) 97.

Yu H L, Tieu A K, Lu C, Liu X H, Godbole A, and Kong C, Mater Sci Eng A 568 (2013) 212.

Fritsch S, Hunger S, Scholze M, Hockauf M, and Wagner M F X, Mater Sci Eng Tech 42 (2011) 573.

Weiss M, Taylor A S, Hodgson P D, and Stanford N, Acta Mater 61 (2013) 5278.

Yuan Q, Xu G, Tian J Y, and Liang W C, Arab J Sci Eng 42 (2017) 4771.

Okitsu Y, Takatab N, and Tsuji N, Scripta Mater 60 (2009) 76.

Tian J Y, Xu G, Liang W C, and Yuan Q, Metallogr Microstruct Anal 6 (2017) 233.

Tsuji N, and Maki T, Scripta Mater 60 (2009) 1044.

Hosseini S M, Alishahi M, Najafizadeh A, and Kermanpur A, Mater Lett 74 (2012) 206.

Wang T S, Zhang F C, Zhang, M and Lv B, Metall Mater Trans A 485 (2008) 456.

Ueji R, Tsuji N, Minamino Y, and Koizumi Y, Sci Technol Adv Mat 5 (2004) 153.

Li X, Jing T F, Lu M M, and Zhang J W, J Mater Eng Perform 21 (2012) 1496.

Alizamini H A, Militzer M, and Poole W J, Scripta Mater 57 (2007) 1065.

Hamzeh M, Kermanpur A, and Najafizadeh A, Mater Sci Eng A 593 (2014) 24.

Acknowledgements

The authors gratefully acknowledge the financial supports from The Major Projects of Technology Innovation of Hubei Province (2017AAA116), the National Natural Science Foundation of China (NSFC) (Nos. 51874216 and 51704217), and Hebei Joint Research Fund for Iron and Steel (E2018318013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuan, Q., Xu, G., Liu, M. et al. Evaluation of Mechanical Properties and Microstructures of Ultrafine Grain Low-Carbon Steel Processed by Cryorolling and Annealing. Trans Indian Inst Met 72, 741–749 (2019). https://doi.org/10.1007/s12666-018-1526-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1526-2