Abstract

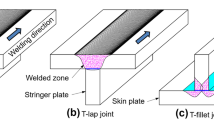

In this article, the AZ31B/2024-T4 T-lap joint was successfully fabricated by friction stir welding (FSW) with different welding parameters. The defect characteristics and metallurgical structure were observed and analyzed using optical microscope and scanning electron microscopy. Besides, the effects of defects and welding parameters on mechanical properties were investigated. The results show that an effective metallurgical reaction zone can be formed between Mg and Al (Mg–Al MRZ). The T-joints without tunnel defects can be obtained and the excellent mechanical properties of the T-joint are achieved using the welding speed of 50 mm/min. The tensile strength along the skin and the stringer is mainly affected by the kiss bonding defects. The maximum tensile strength of the joint reaches 92% of the base metal.

Similar content being viewed by others

References

Liu G, Ma L.N, and Ma Z.D, Acta Metall Sin-engl 31 (2018) 859.

Liu W, Yan Y, Sun T, and Wu S, Int J Adv Manuf Tech 105 (2019) 5211.

Prasad B, Neelaiah G, Krishna M, Ramana S, and Sunil B, J Magnes Alloy 6 (2018) 74.

Fratini L, Buffa G, and Shivpuri R, Mater Design 30 (2009) 2438.

Yang Y. K., Dong H., and Cao H, Weld J 87 (2010) 209.

Li P, Nie F, Dong H, Li S, Yang G, and Zhang H, J Mater Eng Perform 27 (2018) 4765.

Fomin, Fedor, Froend, Martin, Ventzke, and Volker, Int J Adv Manuf Tech 97 (2018) 2022.

Liang Z, Chen K, and Wang X, Metall Mater Trans A 44 (2013) 3727.

Shi, Hui, Chen, Ke, Liang, and Zhiyuan, J Mater Sci Technol 33 (2017) 361.

Sameer M D and Anil K B, J Magnes Alloy 7 (2019) 260.

Mohammadi J, Behnamian Y, Mostafaei A, Izadi H, Saeid T, and Kokabi A, Mater Charact 101 (2015) 196.

Deng H B, Chen Y H, and Zhang T M, Mater Lett 255 (2019).

Ji S, Niu S, and Liu J, J Mater Sci Technol 35 (2019) 1715.

Cui L and Yang X.Q, Mat Sci Eng A 543 (2012) 60.

Zhao Y and Zhou L, Mater Design 57 (2014) 150.

Feistauer E, Bergmann L, and Dos Santos J, Mat Sci Eng A 731 (2018) 461.

Buffa G, Fratini L, and Micari F, Int J Mater Form 1 (2008) 1284.

Fratini L, Buffa G, and Filice L, P I Mech Eng B-J Eng 220 (2006) 672.

Naik, B S, Chen D L, and Cao X, Merall Mater Trans A 45 (2014) 4645.

Yan Y, Shen Y, and Guo C, Int J Mater Form 12 (2018) 850.

Jesus J S, Costa J M, and Loureiro A, J Mater Process Tech 255 (2018) 392.

Liu W, Shen Y, and Guo C, J Mater Eng Perform 28 (2019) 4611.

Sato Y, Park S, and Michiuchi M, Scripta Mater 50 (2004) 1235.

Han T, Xiao M, Zhang Y, and Shen Y, Mater Manuf Process 34 (2019) 1715.

Mostaan L, Seyyed E, and Ali S, T Indian I Metals 70 (2017) 1873.

Ratna S, Ganesh K.V, and Pavan P, J Magnes Alloy 41 (2016) 18.

Kwon Y J, Shigematsu I, and Saito N, Materials Letters 62 (2008) 3828.

Prasad N, Mohan R, and Malakondaiah G, T Indian I Metals 59 (2006) 330.

Saito K, Hirade T, and Takai K, Metall Mater Trans A 50 (2019) 5100.

Acknowledgements

Funding: This study work was funded by the Graduate Innovation Base (Laboratory) Open Fund of Nanjing University of Aeronautics and Astronautics (No. kfjj20190607). This work was also supported by the College Students’ Innovative Entrepreneurial Training Plan Program.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, T., Wu, S., Shen, Y. et al. Investigation on Friction Stir Welding of Mg/Al T-Joints. Trans Indian Inst Met 74, 3045–3061 (2021). https://doi.org/10.1007/s12666-020-02148-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02148-8