Abstract

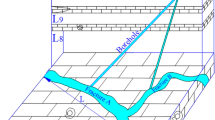

Investigating the diffusion law of slurry while grouting in fractured aquifer is of great significance to the safety in coal mining. In this paper, we comprehensively studied the slurry diffusion in the fractured aquifer, which was grouted through horizontal injection holes. A theoretical model of slurry diffusion in the inclined tubular fractures, as well as the relationship between the distance of slurry diffusion and the grouting time, was established. Then the influence of different factors on the distance of slurry diffusion was analyzed, including rheological coefficient, the fracture width, grouting pressure, the fracture dip angle, and the velocity of flowing water. Finally, sensitivity analysis on the distance of slurry diffusion for pseudoplastic fluid and expansive fluid along the flowing water direction was made and the results show that the sensitivity of each factor to the diffusion distance of the two fluids along the flowing water is different, rheological index is the very significant factor to the diffusion distance of pseudoplastic fluid. However, for the expansive slurry, the fracture width is the very significant factor to the diffusion distance of it.

Similar content being viewed by others

References

Chen TL, Zhang LY, Zhang DL (2014) An FEM/VOF hybrid formulation for fracture grouting modelling. Comput Geotech 58:14–27

Hernqvist L, Christian B, Fransson A, Gustafson G, Funehag J (2012) A hard rock tunnel case study: characterization of the waterbearing fracture system for tunnel grouting. Tunn Undergr Space Technol 30(4):132–144

Hu Y, Liu WQ, Ma TR, Yang R, Liang DX (2019) Analysis on the stability of the inclined water-resisting roof layer while mining under the confined aquifer. Geotech Geol Eng 37(2):995–1006

Li SC, Liu RT, Zhang QS, Zhang X (2016) Protection against water or mud inrush in tunnels by grouting: a review. J Rock Mech Geol Eng 8(5):753–766

Liang YK, Sui WH, Qi JF (2019) Experimental investigation on chemical grouting of inclined fracture to control sand and water flow. Tunn Undergr Space Technol 83:82–90

Liu Q, Sun L (2019) Simulation of coupled hydro-mechanical interactions during grouting process in fractured media based on the combined finite-discrete element method. Tunn Undergr Space Technol 84:472–486

Liu WT, Mu DR, Xie XX, Yang L, Wang DH (2018) Sensitivity analysis of the main factors controlling floor failure depth and a risk evaluation of floor water inrush for an inclined coal seam. Mine Water Environ 37(3):636–648

Mohajerani S, Baghbanan A, Bagherpour R, Hashemolhosseini H (2015) Grout penetration in fractured rock mass using a new developed explicit algorithm. Int J Rock Mech Min Sci 80:412–417

Rafi JY, Stille H (2015) Basic mechanism of elastic jacking and impact of fracture aperture change on grout spread, transmissivity and penetrability. Tunn Undergr Sp Tech 49:174–187

Ruan WJ (2005) Research on diffusion of grouting and basic properties of grouts. Chin J Geotech Eng 27(1):69–73 (in Chinese)

SACMSC (State Administration of Coal Mine Safety of China) (2009) Interpretation of the regulations of mine water disaster prevention. China Univ of Mining and Technology Press, Xuzhou (in Chinese)

Sui WH, Liu JY, Hu W, Qi JF, Zhan KY (2015) Experimental investigation on sealing efficiency of chemical grouting in rock fracture with flowing water. Tunn Undergr Space Technol 50(1):239–249

Sun J, Miao XX (2017) Water-isolating capacity of an inclined coal seam floor based on the theory of water-resistant key strata. Mine Water Environ 36(2):310–322

Sun WH, Liu JY, Yang SG, Chen ZS, Hu YS (2011) Hydrogeological analysis and salvage of a deep coalmine after an underground water inrush. Environ Earth Sci 62(4):735–749

Tani ME (2012) Grouting rock fractures with cement grout. Rock Mech Rock Eng 45(4):547–561

Wang L, Li T (2013) Calculation of grouting diffusion radius on based bingham fluid for chunnel that passes through fractured rock mass. Appl Mech Mater 256–259:1280–1286

Yang P, Li TB, Song L, Deng T, Xue SB (2016) Effect of different factors on propagation of carbon fiber composite cement grout in a fracture with flowing water. Constr Build Mater 121:501–506

Yu WS, Li P, Zhang X, Wang Q (2014) Model test research on hydrodynamic grouting for single fracture with variable inclinations. Rock Soil Mech 35(8):2137–2143 (in Chinese)

Yu SF, Wu AX, Wang YM, Li T (2017) Pre-reinforcement grout in fractured rock masses and numerical simulation for optimizing shrinkage stoping configuration. J Cent South Univ 24(12):2924–2931

Zhan KY, Sui WH, Gao Y (2011) A model for grouting into single fracture with flowing water. Rock Soil Mech 32(6):1659–1663 (in Chinese)

Zhan KY, Sui WH, Wang WX (2012) Correlation analysis of seepage pressure and water plugging effect during grouting into a fracture with flowing water. Rock Soil Mech 33(9):2650–2655 (in Chinese)

Zhang M, Wang XH, Wang Y (2011) Diffusion of Herschel–Bulkley slurry in fractures. Chin J Geotech Eng 33(5):815–820 (in Chinese)

Zhang WJ, Li SC, Wei JC, Zhang QS, Liu RT, Zhang X, Yin HY (2018) Grouting rock fractures with cement and sodium silicate grout. Carbonate Evaporite 33:211–222

Zhao QB, Bi C, Hu WY, Wang HQ, Nan SH, Liu ZB, Chuai XY (2016) Study and application of three-stage seriflux diffusion mechanism in the fissure of aquifer with horizontal injection hole. J China Coal Soc 41(5):1212–1218 (in Chinese)

Zhou ZL, Du XM, Chen Z, Zhao YL (2017) Grouting pressure of exponential fluids based on Navier–Stokes equation. J Cent South Univ 48(7):1824–1830

Zolfaghari A, Bidar AS, Javan MRM, Haftani M, Mehinrad A (2015) Evaluation of rock mass improvement due to cement grouting by Q-system at Bakhtiary dam site. Int J Rock Mech Min Sci 74:38–44

Acknowledgements

This study was supported by the Special Subject Grant of National “973” Basic Research Program of China (no. 2015CB251602), National Science and Technology Major (2016ZX05043), Jiangsu Natural Science Foundation (BK20180636), Independent Innovation Project for Double First-level Construction of CUMT (2018ZZCX04), Advance Research Program of (LTKY201803), and China and Jiangsu Postdoctoral Science Foundation (2019M65201).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, Y., Liu, W., Shen, Z. et al. Diffusion mechanism and sensitivity analysis of slurry while grouting in fractured aquifer with horizontal injection hole. Carbonates Evaporites 35, 49 (2020). https://doi.org/10.1007/s13146-020-00587-4

Accepted:

Published:

DOI: https://doi.org/10.1007/s13146-020-00587-4