Abstract

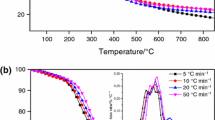

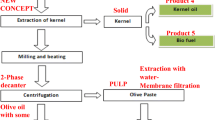

The aim of this study is to present an alternative approach for disposal by using pyrolysis for dry olive pomace (which is the leftover portion of raw olive pomace), which constitutes a problem in olive oil production facilities. In this context, dry olive pomace was pyrolyzed at 600 °C and two different pyrolysis durations: 5 °C/min heating rate without retention (total pyrolysis duration is 80 min) and 1 °C/min heating rate with 30-min retention after reaching target pyrolysis temperature (total pyrolysis duration is 550 min). Afterward, the effects of the dry olive pomace mixed with the olive mill wastewater and the pomace particle size during the pyrolysis process were evaluated in terms of pyrolysis product yields, inorganic contents of chars and organic fractions of bio-oil. While mixing of pomace within the wastewater resulted in an increase in the pyrolysis liquid, the effects of pomace particle size on pyrolysis product yields changed based on the pyrolysis conditions. A decrease in the particle size from 2 to 0.85 mm resulted in an increase in gas by 37.3% and a decrease in liquid by 37% at the pyrolysis process of 80 min. Furthermore, the decrease in the pomace size in grinding preprocess enhanced pyrolysis liquid quality in terms of a decrease in oxygenated compounds by 5–13% and an increase in aliphatic compounds by 7–20% at both pyrolysis durations. Consequently, dry olive pomace pyrolysis can be stated as one of the effective alternatives for safe disposal by converting waste into useful end products.

Graphic abstract

Similar content being viewed by others

References

Aktaş A, Özer S (2014) Ham pirina yağının biyodizel potansiyelinin araştırılması. SDÜ Ziraat Fakültesi Dergisi 3(1):132–139 (in Turkish)

Ali N, Saleem M, Shahzad K, Hussain S, Chughtai A (2016) Effect of operating parameters on production of bio-oil from fast pyrolysis of maize stalk in bubbling fluidized bed reactor. Pol J Chem Technol 18(3):88–96

Apha A, WPCF (2005) Standard methods for examination of water and wastewater, 21st edn. APHA, AWWA, WPCR, New York, p 1

Aquino FL, Hernandez JR, Capareda SC (2007) Elucidating the solid, liquid and gaseous products form pyrolysis of cotton gin trash. In: 2007 ASAE Annual Meeting, 1

ASTM C136–06 (2006) Standard test method for sieve analysis of fine and coarse aggregates. Annual book of ASTM standards. American Society for Testing and Materials, Philadelphia

Bennini MA, Koukouch A, Bakhattar I, Asbik M, Boushaki T, Sarh B, Elorf A, Cagnon B, Bonnamy S (2019) Characterization and combustion of olive pomace in a fixed bed boiler: effects of particle sizes. J Homepage 37(1):229–238

Chouchene A, Jeguirim M, Khiari B, Zagrouba F, Trouvé G (2010) Thermal degradation of olive solid waste: influence of particle size and oxygen concentration. Resour Conserv Recycl 54(5):271–277

Christoforou EA, Fokaides PA, Banks SW, Nowakowski D, Bridgwater AV, Stefanidis S, Kalogiannis KG, Iliopoulou EF, Lappas AA (2018) Comparative study on catalytic and non-catalytic pyrolysis of olive mill solid wastes. Waste Biomass Valorization 9(2):301–313

Dinc G, Yel E (2018a) Self-catalyzing pyrolysis of olive pomace. J Anal Appl Pyrolysis 134:641–646

Dinc G, Yel E (2018b) Kuru ve yaş pirinanin pirolizinde ısıtma hızı ile bekleme süresinin piroliz ürünlerine etkisi. In: Ulusal Katı Atık Yönetimi Kongresi UKAY’2018, 37

Elorf A, Kandasamy J, Belandria V, Bostyn S, Sarh B, Gökalp I (2019) Heating rate effects on pyrolysis, gasification and combustion of olive waste. Biofuels 58:60. https://doi.org/10.1080/17597269.2019.1594598

Encinar J, Gonzalez J, Martínez G, Roman S (2009) Catalytic pyrolysis of exhausted olive oil waste. J Anal Appl Pyrol 85(1):197–203

Engineering ToolBox (2017) Melting and boiling point, density and solubility in water for inorganic compounds. https://www.engineeringtoolbox.com/inorganic-salt-melting-boiling-point-water-solubility-density-liquid-d_1984.html

Fathy SA, Mahmoud AE, Rashad MM, Ezz MK, Mohammed AT (2018) Improving the nutritive value of olive pomace by solid state fermentation of Kluyveromyces marxianus with simultaneous production of gallic acid. Int J Recycl Organic Waste Agric 7(2):135–141

Gan J, Yuan W (2008) Thermochemical conversion of mixed biomass and crude glycerol to produce bio-oil. In: 2008 Providence, Rhode Island, June 29–July 2, 2008, 1

Ghouma I, Jeguirim M, Guizani C, Ouederni A, Limousy L (2017) Pyrolysis of olive pomace: degradation kinetics, gaseous analysis and char characterization. Waste Biomass Valoriz 8(5):1689–1697

Gogoi S, Bhuyan N, Sut D, Narzari R, Gogoi L, Kataki R (2019) Agricultural wastes as feedstock for thermo-chemical conversion: products distribution and characterization. In: Ghosh SK (ed) Energy recovery processes from wastes. Springer, Berlin, pp 115–128

Guedes RE, Luna AS, Torres AR (2018) Operating parameters for bio-oil production in biomass pyrolysis: a review. J Anal Appl Pyrol 129:134–149

Guida M, Hannioui A (2016) A review on thermochemical treatment of biomass: pyrolysis of olive mill wastes in comparison with other types of biomass. Prog Agric Eng Sci 12(1):1–23

Hawash S, Farah JY, El-Diwani G (2017) Pyrolysis of agriculture wastes for bio-oil and char production. J Anal Appl Pyrol 124:369–372

He B, Zhang Y, Yin Y, Funk T, Riskowski G (2000) Operating temperature and retention time effects on the thermochemical conversion process of swine manure. Trans ASAE 43(6):1821

Hmid A, Mondelli D, Fiore S, Fanizzi FP, Al Chami Z, Dumontet S (2014) Production and characterization of biochar from three-phase olive mill waste through slow pyrolysis. Biomass Bioenerg 71:330–339

Jahirul MI, Rasul MG, Chowdhury AA, Ashwath N (2012) Biofuels production through biomass pyrolysis: a technological review. Energies 5(12):4952–5001

Jouhara H, Ahmad D, van den Boogaert I, Katsou E, Simons S, Spencer N (2017) Pyrolysis of domestic based feedstock at temperatures up to 300 C. Therm Sci Eng Prog 5:117–143

Kabakci SB, Aydemir H (2014) Pyrolysis of olive pomace and copyrolysis of olive pomace with refuse derived fuel. Environ Prog Sustain Energy 33(2):649–656

Kan T, Strezov V, Evans TJ (2016) Lignocellulosic biomass pyrolysis: a review of product properties and effects of pyrolysis parameters. Renew Sustain Energy Rev 57:1126–1140

Lee KH (2007) Pyrolysis of municipal plastic wastes separated by difference of specific gravity. J Anal Appl Pyrol 79:1–15

Lin F, Waters CL, Mallinson RG, Lobban LL, Bartley LE (2015) Relationships between biomass composition and liquid products formed via pyrolysis. Front Energy Res 3:45

Liu C, Wang H, Karim AM, Sun J, Wang Y (2014) Catalytic fast pyrolysis of lignocellulosic biomass. Chem Soc Rev 43(22):7594–7623

Lopez A, Marco DI, Caballero BM, Laresgoiti MF, Adrados A (2011) Influence of time and temperature on pyrolysis of plastic wastes in a semi-batch reactor. Chem Eng J 173:62–67

Luo S, Xiao B, Hu Z, Liu S, Guan Y, Cai L (2010) Influence of particle size on pyrolysis and gasification performance of municipal solid waste in a fixed bed reactor. Bioresour Technol 101(16):6517–6520

Lyu G, Wu S, Zhang H (2015) Estimation and comparison of bio-oil components from different pyrolysis conditions. Front Energy Res 3:28

Miandad R, Nizami AS, Rehan M, Barakat MA, Khan MI, Mustafa A, Ismail IMI, Murphy JD (2016) Influence of temperature and reaction time on the conversion of polystyrene waste to pyrolysis liquid oil. Waste Manag 58:250–259

Niu H, Liu N (2014) Effect of particle size on pyrolysis kinetics of forest fuels in nitrogen. Fire Saf Sci 11:1393–1405

Oladeji J, Itabiyi E, Okekunle P (2015) A comprehensive review of biomass pyrolysis as a process of renewable energy generation. J Nat Sci Res 5(5):99–105

Padillaa ERD, Nakashimaa GT, Hanstedb ALS, Santosa LRO, de Barrosc JL, De Contid AC, Yamajia FM (2019) Thermogravimetric and FTIR analyzes of corn cob pyrolysis. Quim Nova 42(5):566–569

Regional Energy Agency of Central Macedonia (2008) Market of olive residues for energy, pp 1–66

Suriapparao DV, Vinu R (2018) Effects of biomass particle size on slow pyrolysis kinetics and fast pyrolysis product distribution. Waste Biomass Valoriz 9(3):465–477

Tsagaraki E, Lazarides HN, Petrotos KB (2007) Olive mill wastewater treatment. In utilization of by-products and treatment of waste in the food industry. Springer, Berlin, pp 133–157

Uzun BB, Putun AE, Putun E (2007) Composition of products obtained via fast pyrolysis of olive-oil residue: effect of pyrolysis temperature. J Anal Appl Pyrol 79(1–2):147–153

Volpe M, D’Anna C, Messineo S, Volpe R, Messineo A (2014) Sustainable production of bio-combustibles from pyrolysis of agro-industrial wastes. Sustainability 6(11):7866–7882

Xiong S, Zhuo J, Zhang B, Yao Q (2013) Effect of moisture content on the characterization of products from the pyrolysis of sewage sludge. J Anal Appl Pyrol 104:632–639

Acknowledgements

This study was financially supported by Selcuk University Coordinatorship of Scientific Research Projects (BAP)-18101003 as MSc thesis project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: M. Abbaspour.

Rights and permissions

About this article

Cite this article

Dinc, G., Yel, E. Alternative approach for safe disposal of dry olive pomace: pyrolysis with/without physical preprocessing. Int. J. Environ. Sci. Technol. 17, 2215–2232 (2020). https://doi.org/10.1007/s13762-019-02612-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-019-02612-z