Abstract

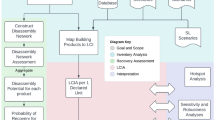

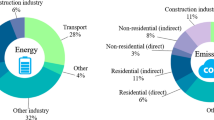

Energy crisis and increasing demand for green energy to acute pollution has forced the engineers, architects and scientists to adapt green materials for structural applications. In this context, conventional building materials are extensively investigated using life cycle estimations, thermodynamic models, CO2 emissions, and energy demands and many other criteria. Selection of smart materials for thermal energy efficient architecture on the bases of various thermo-physical properties (density (ρ), thermal conductivity (K) and specific heat capacity (Cp)) in relation to the engineering requirements (energy stored (QS), energy density (Q′), rate of heat transfer (q), utilization factor (η) and mechanical load) is a crucial as well as a tedious task. In this context, we have employed quality function deployment (QFD) in combination with VlseKriterijumska Optimisacija I Kompromisno Resenje (VIKOR) technique to determine the ranks and rank indices (degree of closeness) of important materials. The weights of thermo-physical properties of materials for hot (ρ: 17.72%; Cp: 45.14%; K: 37.14%) and cold weather (ρ: 29.32%; Cp: 65.42%; K: 5.26%) applications are depicted using QFD. Our results enlighten that low conductivity materials should be preferred for hot areas applications while for cold areas the scenario is reversed. Furthermore, wood and asphalt sheet are found to be the best materials for hot and cold areas, respectively.

Similar content being viewed by others

Abbreviations

- C m :

-

Cost of material

- C p :

-

Specific heat capacity

- K :

-

Thermal conductivity

- P r :

-

QFD priorities

- q :

-

Rate of heat transfer

- Q EV :

-

Losses due to enhanced ventilation or internal cooling

- Q IG :

-

Internal gains due to appliances and human heat

- Q S :

-

Heat stored in material

- Q SG :

-

Solar heat gain

- Q SH :

-

Net heat of the controlled space

- Q TL :

-

Transmission losses between surroundings and the control surface or control surface and the system

- Q V :

-

Heat loss covers ventilation losses

- Q′ :

-

Energy density

- W j :

-

QFD weights

- V :

-

Volume

- η :

-

Utilization factor

- ρ :

-

Density

References

Cole RJ, Kernan PC (1996) Life-cycle energy use in office buildings. Build Environ 31(4):307–317

Huberman N, Pearlmutter D (2008) A life-cycle energy analysis of building materials in the Negev desert. Energy Build 40(5):837–848

Kneifel J (2010) Life-cycle carbon and cost analysis of energy efficiency measures in new commercial buildings. Energy Build 42(3):333–340

Ramesh T, Prakash R, Shukla K (2010) Life cycle energy analysis of buildings: an overview. Energy Build 42(10):1592–1600

Scheuer C, Keoleian GA, Reppe P (2003) Life cycle energy and environmental performance of a new university building: modeling challenges and design implications. Energy Build 35(10):1049–1064

Yohanis Y, Norton B (2002) Life-cycle operational and embodied energy for a generic single-storey office building in the UK. Energy 27(1):77–92

Kua H, Lee S (2002) Demonstration intelligent building—a methodology for the promotion of total sustainability in the built environment. Build Environ 37(3):231–240

Venkatarama Reddy B, Jagadish K (2003) Embodied energy of common and alternative building materials and technologies. Energy Build 35(2):129–137

Barreira E, de Freitas VP (2007) Evaluation of building materials using infrared thermography. Constr Build Mater 21(1):218–224

Lechner N (2009) Heating, cooling, lighting: sustainable design methods for architects. Wiley, Hoboken

Ståhl F (2009) Influence of thermal mass on the heating and cooling demands of a building unit. Chalmers University of Technology, Göteborg

Hinnells M (2008) Technologies to achieve demand reduction and microgeneration in buildings. Energy Policy 36(12):4427–4433

Asan H, Sancaktar Y (1998) Effects of wall’s thermophysical properties on time lag and decrement factor. Energy Build 28(2):159–166

Suzuki M, Oka T, Okada K (1995) The estimation of energy consumption and CO2 emission due to housing construction in Japan. Energy Build 22(2):165–169

Buchanan AH, Honey BG (1994) Energy and carbon dioxide implications of building construction. Energy Build 20(3):205–217

Majumdar M (2001) Energy-efficient buildings in India. TERI Press, New Delhi

Tatsidjodoung P, Le Pierrès N, Luo L (2013) A review of potential materials for thermal energy storage in building applications. Renew Sustain Energy Rev 18:327–349

Navarro M, Martínez M, Gil A, Fernández A, Cabeza L, Olives R, Py X (2012) Selection and characterization of recycled materials for sensible thermal energy storage. Sol Energy Mater Sol Cells 107:131–135

Khare S, Dell’Amico M, Knight C, McGarry S (2013) Selection of materials for high temperature sensible energy storage. Sol Energy Mater Sol Cells 115:114–122

Fernandez A, Martínez M, Segarra M, Martorell I, Cabeza L (2010) Selection of materials with potential in sensible thermal energy storage. Sol Energy Mater Sol Cells 94(10):1723–1729

Thormark C (2006) The effect of material choice on the total energy need and recycling potential of a building. Build Environ 41(8):1019–1026

Akao Y (1997) QFD: past, present, and future. In: International symposium on QFD, 1997. pp 1–12

Prasad B (1998) Review of QFD and related deployment techniques. J Manuf Syst 17(3):221–234

Karsak EE, Sozer S, Alptekin SE (2003) Product planning in quality function deployment using a combined analytic network process and goal programming approach. Comput Ind Eng 44(1):171–190

Mayyas A, Shen Q, Mayyas A, Shan D, Qattawi A, Omar M (2011) Using quality function deployment and analytical hierarchy process for material selection of body-in-white. Mater Design 32(5):2771–2782

Prasad K, Chakraborty S (2013) A quality function deployment-based model for materials selection. Mater Design 45:525–535

Sen P, Yang J-B (1998) Multiple criteria decision support in engineering design, vol 4. Springer, London

Saaty TL (1990) How to make a decision: the analytic hierarchy process. Eur J Oper Res 48(1):9–26

Rao RV (2006) A material selection model using graph theory and matrix approach. Mater Sci Eng, A 431(1):248–255

Opricovic S, Tzeng G-H (2007) Extended VIKOR method in comparison with outranking methods. Eur J Oper Res 178(2):514–529

Deng HYC, Willis RJ (2000) Inter-company comparison using TOPSIS with objective weights. Comput Oper Res 27:963–973

Vats G (2014) Multi-attribute decision making for ferroelectric materials selection. Lambert Academic Publishers, Saarbrücken

Vats G, Sharma M, Vaish R, Chauhan VS, Madhar NA, Shahabuddin M, Parakkandy JM, Batoo KM (2015) Application oriented selection of optimal sintering temperature from user perspective: a study on K0.5Na0.5NbO3 Ceramics. Ferroelectrics 481(1):64–76

Vats G, Vaish R (2013) Piezoelectric material selection for transducers under fuzzy environment. J Adv Ceram 2(2):141–148

Vats G, Vaish R (2014) Selection of optimal sintering temperature of K0.5Na0.5NbO3 ceramics for electromechanical applications. J Asian Ceram Soc 2(1):5–10

Vats G, Vaish R (2014) Phase change materials selection for latent heat thermal energy storage systems (LHTESS): an industrial engineering initiative towards materials science. Adv Sci Focus 2(2):140–147

Vats G, Vaish R (2014) Selection of lead-free piezoelectric ceramics. Int J Appl Ceram Technol 11(5):883–893

Vats G, Vaish R, Bowen CR (2015) Selection of ferroelectric ceramics for transducers and electrical energy storage devices. Int J Appl Ceram Technol 12(S1):E1–E7

Vats S, Vats G, Vaish R, Kumar V (2014) Selection of optimal electronic toll collection system for India: a subjective-fuzzy decision making approach. Appl Soft Comput 21:444–452

Athawale VM, Chakraborty S (2012) Material selection using multi-criteria decision-making methods: a comparative study. Proc Inst Mech Eng Part L J Mater Design Appl 226(4):266–285

Goverse T, Hekkert MP, Groenewegen P, Worrell E, Smits RE (2001) Wood innovation in the residential construction sector; opportunities and constraints. Resour Conserv Recycl 34(1):53–74

Debnath A, Singh S, Singh Y (1995) Comparative assessment of energy requirements for different types of residential buildings in India. Energy Build 23(2):141–146

Acknowledgements

One of the author (Rahul Vaish) acknowledges the support from Indian National Science Academy (INSA), New Delhi, through a grant by the Department of Science and Technology (DST), New Delhi, India under the INSPIRE faculty award-2011 (ENG-01).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vats, G., Vaish, R. Smart Materials Selection for Thermal Energy Efficient Architecture. Proc. Natl. Acad. Sci., India, Sect. A Phys. Sci. 89, 11–21 (2019). https://doi.org/10.1007/s40010-017-0364-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40010-017-0364-7