Abstract

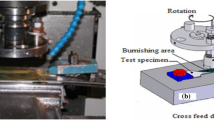

Burnishing is cold working process in which hard balls are pressed against the surface, resulting in improved surface finish. The surface gets compressed and then plasticized. This is a highly finishing process which is becoming more popular. Surface quality of the product improves its aesthetic appearance. The product made up of aluminum material is subjected to burnishing process during which kerosene is used as a lubricant. In this study factors affecting burnishing process such as burnishing force, speed, feed, work piece diameter and ball diameter are considered as input parameters while surface finish is considered as an output parameter In this study, experiments are designed using 25 factorial design in order to analyze the relationship between input and output parameters. The ANOVA technique and F-test are used for further analysis.

Similar content being viewed by others

References

S.M. Wu, Tool-life testing by response surface methodology—Part 1. J. Manuf. Sci. Eng. 86(2), 105–110 (1964)

N.H. Loh, S.C. Tam, S. Miyazawa, A study of the effects of ball-burnishing parameters on surface roughness using factorial design. J. Mech. Work. Technol. 18(1), 53–61 (1989)

M.A. Elbaradie, Surface roughness model for turning grey cast iron (154 BHN). Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 207(1), 43–54 (1993)

A.M. Hassan, A.M. Momani, Further improvements in some properties of shot peened components using the burnishing process. Int. J. Mach. Tools Manuf. 40(12), 1775–1786 (2000)

M.H. El-Axir, An investigation into roller burnishing. Int. J. Mach. Tools Manuf. 40(11), 1603–1617 (2000)

U.M. Shirsat, B.B. Ahuja, Parametric analysis of combined turning and ball burnishing process. Indian J. Eng. Mater. Sci. 11(5), 391–396 (2004)

De Lacalle, L.N. Lopez, A. Lamikiz, J. Munoa, J.A. Sánchez, Quality improvement of ball-end milled sculptured surfaces by ball burnishing. Int. J. Mach. Tools Manuf 45(15), 1659–1668 (2005)

L. Luca, S. Neagu-Ventzel, I. Marinescu, Effects of working parameters on surface finish in ball-burnishing of hardened steels. Precis. Eng. 29(2), 253–256 (2005)

U. Esme, Use of grey based Taguchi method in ball burnishing process for the optimization of surface roughness and microhardness of AA 7075 aluminum alloy. Mater. Technol. 44(3), 129–135 (2010)

A. Sagbas, Analysis and optimization of surface roughness in the ball burnishing process using response surface methodology and desirabilty function. Adv. Eng. Softw. 42(11), 992–998 (2011)

K.O. Low, K.J. Wong, Influence of ball burnishing on surface quality and tribological characteristics of polymers under dry sliding conditions. Tribol. Int. 44(2), 144–153 (2011)

F.L. Li, W. Xia, Z.Y. Zhou, J. Zhao, Z.Q. Tang, Analytical prediction and experimental verification of surface roughness during the burnishing process. Int. J. Mach. Tools Manuf. 62, 67–75 (2012)

W. Grzesik, K. Żak, Modification of surface finish produced by hard turning using superfinishing and burnishing operations. J. Mater. Process. Technol. 212(1), 315–322 (2012)

Acknowledgments

Authors would like to thank Production Engineering Department, Government College of Engineering, Pune (India), for rendering help in the technical aspects of this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shirsat, U., Ahuja, B. & Dhuttargaon, M. Effect of Burnishing Parameters on Surface Finish. J. Inst. Eng. India Ser. C 98, 431–436 (2017). https://doi.org/10.1007/s40032-016-0320-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-016-0320-3