Abstract

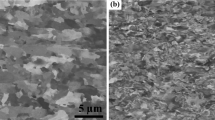

The development of new welding consumables requires several samples and experiments that must be performed to achieve the required mechanical properties. In the development of a metal-cored wire with a target tensile strength of 1150 MPa and acceptable impact toughness, thermodynamic and kinetic calculations via MatCalc were used to reduce the experimental work and the resources required. Micro-alloying elements were employed to obtain high strength as an alternative approach to conventional solid solution hardening. Investigations of the microstructure were performed via atom probing to understand the effects of micro-alloying elements. In particular, the influences of different elements on the precipitation behaviour in the weld metal were evaluated. The calculated mechanical properties are in accordance with the results obtained from experiments and can be explained by microstructural investigations. The approach is exemplified through vanadium and clarifies an efficient development route.

Similar content being viewed by others

References

Jiang QL, Li YJ, Wang J, Zhang L (2011) Effects of inclusions on formation of acicular ferrite and propagation of crack in high strength low alloy steel weld metal. Mater Sci Technol 27(10):1565–1569. https://doi.org/10.1179/026708310X12815992418535

Sumi H, Oi K, Yasuda K (2015) Effect of chemical composition on microstructure and mechanical properties of laser weld metal of high-tensile strength steel. Welding in the World 59(2):173–178. https://doi.org/10.1007/s40194-014-0191-2

Bajic N, Sijacki-Zeravcic V, Bobic B, Cikara D, Arsic M (2011) Filler metal influence on weld metal structure of microalloyed steel. Weld J 90(3):55–62

Lu J, Omotoso O, Wiskel JB, Ivey DG, Henein H (2012) Strengthening mechanisms and their relative contributions to the yield strength of microalloyed steels. Metall Mater Trans A 43(9):3043–3061. https://doi.org/10.1007/s11661-012-1135-3

Haslberger P, Ernst W, Schnitzer R (2017) High resolution imaging of martensitic all-weld metal. Sci Technol Weld Join 22(4):336–342. https://doi.org/10.1080/13621718.2016.1240980

Keehan E, Karlsson L, Andrén HO, Svensson LE (2006) New developments with C–Mn–Ni in high strength steel weld metals—part B. Mechanical properties. Weld J 85(10):218–224

Keehan E, Andrén O, Karlsson L, Murugananth M, Bhadeshia H (2002) Microstructural and mechanical effects of nickel and manganese on high strength weld metals. Trends in Welding Research: 695–700

Keehan E, Karlsson L, Andrén H O (2006) Influence of carbon, manganese and nickel on microstructure and properties of strong steel weld metals: part 1–effect of nickel content. Sci Technol Weld Join 11.1: 1–8

Keehan E, Karlsson L, Andrén HO, Bhadeshia H (2006) Influence of carbon, manganese and nickel on microstructure and properties of strong steel weld metals: part 2–impact toughness gain resulting from manganese reductions. Sci Technol Weld Join 11(1):9–18. https://doi.org/10.1179/174329306X77849

Beidokhti B, Koukabi AH, Dolati A (2009) Influences of titanium and manganese on high strength low alloy SAW weld metal properties. Mater Charact 60(3):225–233. https://doi.org/10.1016/j.matchar.2008.09.005

Bhole SD, Nemade JB, Collins L, Liu C (2006) Effect of nickel and molybdenum additions on weld metal toughness in a submerged arc welded HSLA line-pipe steel. J Mater Process Technol 173(1):92–100. https://doi.org/10.1016/j.jmatprotec.2005.10.028

Crockett DD, Rhone JA, Young RF, Noernberg DC (1995) Design considerations for submerged arc consumables intended for the manufacture of line pipe. Pipeline Technol 1:151–162

Keehan KL, Andrén HO, Bhadeshia H (2006) Influence of C, Mn and Ni contents on microstructure and properties of strong steel weld metals, part III. Increased strength from carbon additions. Sci Technol Weld Join 11(1):19–24. https://doi.org/10.1179/174329306X77858

Johnson MQ, Evans GM, Edwards GR (1995) The influence of titanium additions and interpass temperature on the microstructures and mechanical properties of high strength SMA weld metals. ISIJ Int 35(10):1222–1231. https://doi.org/10.2355/isijinternational.35.1222

Sasaki M, Matsuura K, Ohsasa K, Ohno M (2009) Effects of addition of titanium and boron on columnar austenite grain in carbon steel. ISIJ Int 49(9):1367–1371. https://doi.org/10.2355/isijinternational.49.1367

Midawi ARH, Santos EBF, Huda N, Sinha AK, Lazor R, Gerlich AP (2015) Microstructures and mechanical properties in two X80 weld metals produced using similar heat input. J Mater Process Technol 226:272–279. https://doi.org/10.1016/j.jmatprotec.2015.07.019

Quintana MA, McLane J, Babu SS, David SA (2001) Inclusion formation in self-shielded flux cored arc welds. Weld J-New York 80(4):98S–105S

Evans GM (1995) Microstructure and properties of ferritic steel welds containing Al and Ti. Weld J 74:8

Vanovsek W, Bernhard C, Fiedler M, Posch G (2013) Influence of aluminum content on the characterization of microstructure and inclusions in high-strength steel welds. Weld World 57(1):73–83. https://doi.org/10.1007/s40194-012-0008-0

Lan L, Kong X, Qiu C, Zhao D (2016) Influence of microstructural aspects on impact toughness of multi-pass submerged arc welded HSLA steel joints. Mater Des 90:488–498. https://doi.org/10.1016/j.matdes.2015.10.158

Narayanan BK, Kovarik L, Sarosi PM, Quintana MA, Mills MJ (2010) Effect of microalloying on precipitate evolution in ferritic welds and implications for toughness. Acta Mater 58(3):781–791

Jiang QL, Li YJ, Wang J, Zhang L (2011) Effects of Mn and Ti on microstructure and inclusions in weld metal of high strength low alloy steel. Mater Sci Technol 27(9):1385–1390. https://doi.org/10.1179/026708310X12701149768052

Gladman T (1997) The physical metallurgy of microalloyed steels. Institute of materials, London

Lagneborg R, Hutchinson B, Siwecki T, Zajac S (2014) The role of vanadium in microalloyed steels. J Min Mater Charact Eng. 2(5)

Schnitzer R, Zügner D, Haslberger P, Ernst W, Kozeschnik E (2016) Influence of alloying elements on the mechanical properties of ultra-high strength weld metal. IIW document: II-C-491-16

Zügner D (2015) Influence of microalloying elements on the mechanical properties of ultra-high strength welds. Master thesis

Haslberger P, Holly S, Ernst W, Schnitzer R (2017) Precipitates in microalloyed ultra-high strength weld metal studied by atom probe tomography. IIW document: II-C-534-17

Acknowledgements

The K-Project Network of Excellence for Metal JOINing is fostered in the framework of COMET (Competence Centers for Excellent Technologies) by BMWFW, BMVIT, FFG, Land Oberösterreich, Land Steiermark, Land Tirol and SFG. The COMET programme is handled by FFG.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission II - Arc welding and Filler Metals

Rights and permissions

About this article

Cite this article

Holly, S., Haslberger, P., Zügner, D. et al. Development of high-strength welding consumables using calculations and microstructural characterisation. Weld World 62, 451–458 (2018). https://doi.org/10.1007/s40194-018-0562-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-0562-1