Abstract

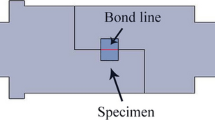

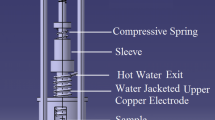

Dissimilar transient liquid phase (TLP) bonding of GTD-111 and IN-718 nickel-based superalloys was investigated using BNi-9 (AWS A5.8/A5.8M) as an interlayer. The effect of the bonding time on the microstructure and mechanical properties of the TLP-bonded specimens was studied at 1100 °C using optical microscopy (OM), scanning electron microscopy (SEM) equipped with energy-dispersive spectrometry (EDS), and micro-hardness and shear strength analyses. Joint microstructural studies revealed that at the bonding times shorter than 75 min, nickel- and chromium-rich borides were formed with the joint centerline. The volume fraction of intermetallic compounds decreased with the increase of the bonding time and the diffusion of boron element whereby the isothermal solidification eventually completed after 75 min. Micro-hardness investigations along the bonding joint showed that the hardness of an isothermal solidification zone (ISZ) decreased with the completion of isothermal solidification. The hardest zone in the joint structure belonged to the athermal solidification zone (ASZ). The shear strength test results showed that incrementing the bonding time increased the shear strength where the shear strength value at 1 min/1100 °C (320 MPa) raised to 590 MPa after the completion of isothermal solidification.

Similar content being viewed by others

References

Pouranvari M, Ekrami A, Kokabi A (2008) Microstructure development during transient liquid phase bonding of GTD-111 nickel-based superalloy. J Alloys Compd 461(1–2):641–647

Shamsabadi AY, Bakhtiari R (2016) TLP bonding of IN738/MBF20/IN718 system. J Alloys Compd 685:896–904

Ojo OA (2004) On liquation cracking of cast Inconel 738LC superalloy welds. Ph.D. Dissertation, University of Manitoba, Canada

Yan P, Wallach E (1993) Diffusion-bonding of TiAl. Intermetallics 1(2):83–97

Campbell CE, Boettinger WJ, Kattner UR (2002) Development of a diffusion mobility database for Ni-base superalloys. Acta Mater 50(4):775–792

Hattori T, Sakai S, Sakamoto A, Fujiwara C (1994) Brazeability of aluminum in vacuum-nitrogen partial-pressure atmosphere brazing. Weld J Incl Weld Res Suppl 73(10):233s

Tung S, Lim L, Lai M, Wu H (1997) Evolution of nickel borides in Ni-Si-B brazed joints of nickel during post-braze heat treatment. Mater Sci Technol 13(12):1051–1056

Rabinkin A (2004) Brazing with (NiCoCr)–B–Si amorphous brazing filler metals: alloys, processing, joint structure, properties, applications. Sci Technol Weld Join 9(3):181–199

Jin T, Li W, Sun X-F, Guan H-R, Hu Z-Q (2008) Creep fracture mechanism of TLP joint of a Ni-base single crystal superalloy. J Alloys Compd 457(1–2):185–190

Qian M, Lippold J (2003) The effect of annealing twin-generated special grain boundaries on HAZ liquation cracking of nickel-base superalloys. Acta Mater 51(12):3351–3361

Ojo O, Richards N, Charturvedi M (2004) Effect of gap size and process parameters on diffusion brazing of Inconel 738. Sci Technol Weld Join 9(3):209–220

Ahn Y, Yoon B, Kim H, Lee C (2002) Effect of dilution on the behavior of solidification cracking in PTAW overlay deposit on Ni-Base superalloys. Met Mater Int 8(5):469–477

Ye X, Hua X, Wang M, Lou S (2015) Controlling hot cracking in Ni-based Inconel-718 superalloy cast sheets during tungsten inert gas welding. J Mater Process Technol 222:381–390

Duvall D, Owczarski W, Paulonis D (1974) TLP bonding: a new method for joining heat resistant alloys. Weld J(NY) 53(4):203–214

Ekrami A, Khan T (1999) Transient liquid phase diffusion bonding of oxide dispersion strengthened nickel alloy MA758. Mater Sci Technol 15(8):946–950

Ekrami A, Khan T, Malik H (2003) Effect of transient liquid phase diffusion bonding on properties of ODS nickel alloy MA758. Mater Sci Technol 19(1):132–136

Bakhtiari R, Shamsabadi AY, Moradi KA (2020) Shear strength/microstructure relationship for dissimilar IN738/IN718 TLP joints. Weld World 64(1):219–231

MacDonald W, Eagar T (1992) Transient liquid phase bonding. Annu Rev Mater Sci 22(1):23–46

Tuah-Poku I, Dollar M, Massalski T (1988) A study of the transient liquid phase bonding process applied to a Ag/Cu/Ag sandwich joint. Metall Trans A 19(3):675–686

Paulonis D, Oblak J, Duvall D (1969) Precipitation in nickel-base alloy 718. Pratt and Whitney Aircraft, Middletown, Conn

Pouranvari M, Ekrami A, Kokabi A (2013) Solidification and solid state phenomena during TLP bonding of IN718 superalloy using Ni–Si–B ternary filler alloy. J Alloys Compd 563:143–149

Schilke P, Beltran A, Foster A, Pepe J (1996) Advanced Gas Turbine Materials and Coatings, 39th GE Turbine State-of-the-Art Technology Seminar. GE Power Systems, GER-3569F, 22

Amiri D, Sajjadi SA, Bakhtiari R, Kamyabi-Gol A (2018) The role of TLP process variables in improvement of microstructure and mechanical properties in TLP joints of GTD-111/Ni-Cr-Fe-B-Si/GTD-111 system. J Manuf Process 32:644–655

Ohsasa K, Narita T, Shinmura T (1999) Numerical modeling of the transient liquid phase bonding process of Ni using Ni-B-Cr ternary filler metal. J Ph Equilib 20(3):199–206

Bondar A, MSIT, B (2007) B-Cr-Ni (boron-chromium-nickel) non-ferrous metal ternary systems. Selected soldering and brazing systems: phase diagrams, crystallographic and thermodynamic data. Non-Ferrous Metal Systems. Part 3: Selected Soldering and Brazing Systems, pp 153–167

Siredey-Schwaller N, Hamel-Akré J, Peltier L, Hazotte A, Bocher P (2017) Solidification sequence of Ni-Si-Cr~ 3wt% B brazing alloys. Welding in the World 61(6):1253–1265

Danflou HL, Marty M, Walder A (1992) Formation of serrated grain boundaries and their effect on the mechanical properties in a P/M nickel base superalloy. Superalloys 1992:63–72

Hoffelner W, Kny L, Stickler R, McCall W (1979) Effects of aging treatments on the microstructure of the Ni-base superalloy IN-738. Mater Werkst 10(3):84–92

Daleo A, Wilson JR (1998) GTD111 alloy material study. J Eng Gas Turbines and Power 120:375–381

Sajjadi SA, Nategh S, Guthrie RI (2002) Study of microstructure and mechanical properties of high performance Ni-base superalloy GTD-111. Mater Sci Eng A 325(1–2):484–489

Idowu O, Ojo O, Chaturvedi M (2006) Microstructural study of transient liquid phase bonded cast INCONEL 738LC superalloy. Metall Mater Trans A 37(9):2787–2796

Cieslak M, Stephens J, Carr M (1988) A study of the weldability and weld related microstructure of Cabot alloy 214. Metall Trans A 19(3):657–667

Yuan X, Kim MB, Kang CY (2009) Characterization of transient-liquid-phase-bonded joints in a duplex stainless steel with a Ni–Cr–B insert alloy. Mater Charact 60(11):1289–1297

Sung P, Poirier DR (1999) Liquid-solid partition ratios in nickel-base alloys. Metall Mater Trans A 30(8):2173–2181

Massalski T, Okamoto H, Subramanian P, Kacprzak L (1986) Binary alloy phase diagrams, ASM, Metals Park. Ohio 1987:22

Tung S, Lim L, Lai M (1996) Solidification phenomena in nickel base brazes containing boron and silicon. Scr Mater 34(5):763–769

Surendar A, Lucas A, Abbas M, Rahim R, Salmani M (2019) Transient liquid phase bonding of stainless steel 316 L to Ti-6Al-4 V using Cu/Ni multiinterlayer: microstructure, mechanical properties, and fractography. Weld World 63(4):1025–1032

Gale W, Wallach E (1991) Microstructural development in transient liquid-phase bonding. Metall Trans A 22(10):2451–2457

Pouranvari M, Ekrami A, Kokabi A (2009) Effect of bonding temperature on microstructure development during TLP bonding of a nickel base superalloy. J Alloys Compd 469(1–2):270–275

Pouranvari M, Ekrami A, Kokabi A (2013) TLP bonding of cast IN718 nickel based superalloy: process–microstructure–strength characteristics. Mater Sci Eng A 568:76–82

Pouranvari M (2015) Solid solution strengthening of transient liquid phase bonded nickel based superalloy. Mater Sci Technol 31(14):1773–1780

Farzadi A, Esmaeili H, Mirsalehi S (2019) Transient liquid phase bonding of Inconel 617 superalloy: effect of filler metal type and bonding time. Weld World 63(1):191–200

Pouranvari M, Ekrami A, Kokabi A (2008) Microstructure–properties relationship of TLP-bonded GTD-111 nickel-base superalloy. Mater Sci Eng A 490(1–2):229–234

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of the Topical Collection on Recommended for publication by Commission XVII - Brazing, Soldering and Diffusion Bonding

Rights and permissions

About this article

Cite this article

Ghahferokhi, A.I., Kasiri-Asgarani, M., Amini, K. et al. Evolution of microstructure and mechanical properties on dissimilar transient liquid phase (TLP) bonding of GTD-111 and IN-718 by BNi-9 (AWS A5.8/A5.8M) interlayer. Weld World 65, 329–343 (2021). https://doi.org/10.1007/s40194-020-01014-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-01014-x