Abstract

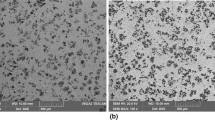

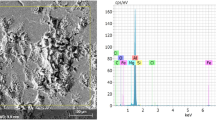

The goal of this research work is to assess the tribological properties of A356 alloy reinforced with 20 wt% SiC composite prepared by liquid metallurgy route. A356 alloy and A356 with 20 wt% SiC composites were manufactured through three different casting techniques such as gravity die casting, stir casting and stir cum squeeze casting. The fabricated castings exhibit improved hardness value of around 680 MPa, 840 MPa and 950 MPa for A356 alloy, A356 with 20 wt% SiC stir cast composite and A356 with 20 wt% SiC stir with squeeze cast composite, respectively. Further, an ultimate tensile strength of 256 MPa, 298 MPa and 331 MPa was obtained for A356 alloy, A356 with 20 wt% SiC stir cast composite and A356 with 20 wt% SiC stir with squeeze cast composite, respectively. The tribological properties of prepared samples were tested using a pin-on-disk tribometer at room temperature under dry sliding condition. The wear results explained that the wear rate and coefficient of friction started to increase with the function of load (10–40 N) under both the sliding distance of 1000 m and 2000 m. The squeeze cast A356 with 20 wt% SiC composite produced less wear rate and a higher coefficient of friction when compared to other samples. This was attributed to effective embedding, bonding and load-carrying capacity of SiC particles over the A356 matrix. This result indicates improved adhesive properties and abrasion resistance in the squeeze cast A356 with 20 wt% SiC composite. Further, the worn surface morphology of squeeze cast samples was examined using a scanning electron microscope to observe mild adhesive wear and damages due to the delamination effect.

Similar content being viewed by others

Data availability

The experimental datasets obtained from this research work and then the analyzed results during the current study are available from the corresponding author on reasonable request.

References

Rana RS, Purohit R, Das S (2013) Tribological behaviour of AA 5083/micron and nano SiC composites fabricated by ultrasonic assisted stir casting process. Int J Sci Res Publ 3(9):1–7

Al-Rubaie KS, Yoshimura HN, De Mello JDB (1999) Two-body abrasive wear of Al–SiC composites. Wear 233-235:444–454. https://doi.org/10.1016/S0043-1648(99)00185-4

Veeresh Kumar GB, Rao CSP, Selvaraj N, Bhagyashekar MS (2010) Studies on Al6061-SiC and Al7075-Al2O3 metal matrix composites. J Miner Mater Charact Eng 9(1):43–55. https://doi.org/10.4236/jmmce.2010.91004

Hashim J, Looney L, Hashmi MSJ (1999) Metal matrix composites: production by the stir casting method. J Mater Process Technol 92(93):1–7. https://doi.org/10.1016/S0924-0136(99)00118-1

Soundararajan R, Ramesh A, Sivasankaran S, Sathishkumar A (2015) Modeling and analysis of mechanical properties of aluminium alloy (A413) processed through squeeze casting route using artificial neural network model and statistical technique. Adv Mater Sci Eng. https://doi.org/10.1155/2015/714762

Soundararajan R, Ramesh A, Mohanraj N, Parthasarathi N (2016) An investigation of material removal rate and surface roughness of squeeze casted A413 alloy on WEDM by multi response optimization using RSM. J Alloy Compd 685:533–545. https://doi.org/10.1016/j.jallcom.2016.05.292

Soundararajan R, Ramesh A, Sivasankaran S, Vignesh M (2017) Modeling and analysis of mechanical properties of Aluminium alloy (A413) reinforced with boron carbide (B4C) processed through squeeze casting process using artificial neural network model and statistical technique. Mater Today 4(2):2008–2030. https://doi.org/10.1016/j.matpr.2017.02.047

Soundararajan R, Saravanakumar P, Sendil PM, Ramesh A, Rajasekaran KM (2018) Effect of squeeze casting process parameters on surface roughness of A413 alloy and A413-B4C composites. Int J Mech Prod Eng Res Dev 8(2):1157–1166

Soundararajan R, Akilesh M, Surya K, Srinivasan S, Sudharson SL (2018) Evaluation of A356-B4C composites fabricated thru ultrasonic assisted stir casting technique. Int J Mech Eng Technol 9(8):727–737

Soundararajan R, Sendil PM, Saravanakumar P, Ramesh A, Sivasankaran S (2018) Effect of die sleeve material on mechanical behavior of A413 aluminium alloy processed through squeeze casting route. Int J Mech Prod Eng Res Dev 8(3):583–590. https://doi.org/10.24247/ijmperdjun201862

Rama Rao S, Padmanabhan G (2012) Fabrication and mechanical properties of aluminium boron carbide composites. Int J Mater Biomater Appl 2(3):15–18

Shalaby EAM, Churyumov AY, Besisa D, Daoud A, El-khair MTA (2017) A comparative study of thermal conductivity and tribological behavior of squeeze cast A359/AlN and A359/SiC composites. J Mater Eng Perform 26(7):3079–3089. https://doi.org/10.1007/s11665-017-2734-3

Ghandvar H, Idris MH, Ahmad N, Moslemi N (2017) Microstructure development, mechanical and tribological properties of a semisolid A356/xSiCp composite. J Appl Res Technol 15(6):533–544. https://doi.org/10.1016/j.jart.2017.06.002

Lashgari HR, Sufizadeh AR, Emamy M (2010) The effect of strontium on the microstructure and wear properties of A356–10%B4C cast composites. Mater Des 31(4):2187–2195. https://doi.org/10.1016/j.matdes.2009.10.049

Radhika N, Raghu R (2016) Investigation on mechanical properties and analysis of dry sliding wear behavior of Al LM13/AlN metal matrix composite based on Taguchi’s technique. J Tribol 139(4):1–18. https://doi.org/10.1115/1.4035155

Sam M, Radhika N (2018) Effect of heat treatment on mechanical and tribological properties of centrifugally cast functionally graded Cu/Al2O3 composite. J Tribol 140(2):1–25. https://doi.org/10.1115/1.4037767

Radhika N, Priyanka MV (2017) Investigation of adhesive wear behaviour of zirconia reinforced aluminium metal matrix composite. J Eng Sci Technol 12(6):1685–1696

Nithesh R, Radhika N, Shiam Sunder S (2016) Mechanical properties and adhesive scuffing wear behaviour of stir cast Cu–Sn–Ni/Si3N4 composites. J Tribol 139(6):1–19. https://doi.org/10.1115/1.4036185

Manu KMS, Sreeraj K, Rajan TPD, Shereema RM, Pai BC, Arun B (2015) Structure and properties of modified compocast microsilica reinforced aluminum matrix composite. Mater Des 88:294–301. https://doi.org/10.1016/j.matdes.2015.08.110

Joshi YG, Gupta AR, Shingarwade RU (2014) Scrutinization of A356/25SiCp AMC and gray cast iron as brake rotor material. Int J Res Advent Technol 2(2):1–7

Ghandvar H, Idris MH, Ahmad N, Moslemi N (2017) Microstructure development, mechanical and tribological properties of a semisolid A356/xSiCp composite. J Appl Res Technol 15:533–544. https://doi.org/10.1016/j.jart.2017.06.002

Rahman MH, Al Rashed HMM (2014) Characterization of silicon carbide reinforced aluminum matrix composites. Procedia Eng 90:103–109. https://doi.org/10.1016/j.proeng.2014.11.821

Bobic I, Ruzic J, Bobic B, Babic M, Vencl A, Mitrovic S (2014) Microstructural characterization and artificial aging of compo-casted hybrid A356/SiCp/Grp composites with graphite macro particles. Mater Sci Eng, A 612:7–15. https://doi.org/10.1016/j.msea.2014.06.028

Ravindran P, Manisekar K, Rathika P, Narayanasamy P (2013) Tribological properties of powder metallurgy—processed aluminium self lubricating hybrid composites with SiC additions. Mater Des 45:561–570. https://doi.org/10.1016/j.matdes.2012.09.015

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Technical Editor: Paulo de Tarso Rocha de Mendonça, Ph.D.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Soundararajan, R., Sivasankaran, S., Babu, N. et al. Appraisal of tribological properties of A356 with 20% SiC composites under dry sliding condition. J Braz. Soc. Mech. Sci. Eng. 42, 147 (2020). https://doi.org/10.1007/s40430-020-2231-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-2231-8