Abstract

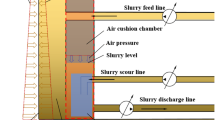

The mud cake of the large-diameter slurry shield severely affects the tunneling efficiency and construction safety, the avoidance and elimination of which largely depends on the scouring characteristics of the nozzle. Based on the solid–liquid two-phase flow theory and dynamic mesh technology, this paper establishes a mud flow model of the nozzle on a slurry shield cutterhead and a cutterhead rotation model and builds a simulation model of the cutterhead nozzle scouring process with CFD. By verifying the simulation model with the self-developed 1 Mpa pressure-bearing scouring test bench, the paper conducts an analysis on how the convergence angle, outlet diameter, and length–diameter ratio of the 12 m large-diameter slurry shield cutterhead affect the scouring characteristics of the nozzle. The results show that when the convergence angle is 13°, the flow fields will be more uniformly distributed inside the nozzle, the average flow rate will be maximized, reaching 3.29 m/s, and the pressure loss will be minimized, thus leading to a relatively good scouring performance. With the assurance of both high flow speed and low pressure loss, the nozzle outlet diameter can be set between 30 and 60 mm for optimal flushing effect; at this point, the average mud flow rate is no less than 3 m/s, and the pressure loss is no more than 106 pa, which can help solve the caking problem to some extent. With the increase in length–diameter ratio, the loss of static pressure and total pressure witnessed a relatively high rise, as result of which a smaller long-diameter ratio will be more appropriate, also considering the mud flow rate reaches a maximum value of 3.24 m/s when the ratio is 3 and satisfying results could be achieved when the above ratio has the value of about 3.

Similar content being viewed by others

References

Sirivachiraporn A, Phienwej N (2012) Ground movements in EPB shield tunnelling of Bangkok subway project and impacts on adjacent buildings. Tunn Undergr Sp Technol 30:10–24

Liu C, Zhang Z, Richard A (2014) Pile and pile group response to tunnelling using a large diameter slurry shield—case study in Shanghai. Comput Geotech 59:21–43

Zizka Z, Schoesser B, Thewes M (2018) Slurry shield tunneling: new methodology for simplified prediction of increased pore pressures resulting from slurry infiltration at the tunnel face under cyclic excavation processes. Int J Civ Eng 4:1–18

Xu T, Bezuijen A (2018) Analytical methods in predicting excess pore water pressure in front of slurry shield in saturated sandy ground. Tunn Undergr Sp Technol 73:203–211

Oh J, Ziegler M (2014) Investigation on influence of tail void grouting on the surface settlements during shield tunneling using a stress-pore pressure coupled analysis. KSCE J Civ Eng 18(3):803–811

Lin C, Zhang Z, Wu S (2012) Case study of slurry shield driving parameters’ influences on ground surface settlements. China Civ Eng J 4:116–126

Feng H, Yu R (2019) Numerical analysis of influence of double-line tunnel shield tunneling on ground surface settlement. J Railw Eng Soc 36(3):78–83

Lu L, Sun J, Zhou G, Tan S, Liu H, Li G (2018) Research on the surface deformation prediction for curved shield construction in clay stratum. J Railw Eng Soc 35(5):99–105

Xia Y, Wang Y, Wu D (2017) Transport characteristics of shield slurry system. J Cent South Univ Sci Technol 48(11):2890–2897

Yang D, Xia Y, Wu D (2018) Numerical investigation of pipeline transport characteristics of slurry shield under gravel stratum. Tunn Undergr Sp Technol 71:223–230

Huang Q, Zou JF, Qian ZH (2019) Face stability analysis for a longitudinally inclined tunnel in anisotropic cohesive soils. J Cent South Univ 26(7):1780–1793

Liu W, Shi P, Chen L, Tang Q (2018) Analytical analysis of working face passive stability during shield tunneling in frictional soils. Acta Geotech 2:1–14

Anagnostou G (2012) The contribution of horizontal arching to tunnel face stability. Geotechnik 35(1):34–44

Chen RP, Li J, Kong LG, Tang LJ (2013) Experimental study on face instability of shield tunnel in sand. Tunn Undergr Sp Technol 33:12–21

Li Y, Emeriault F, Kastner R, Zhang Z (2009) Stability analysis of large slurry shield-driven tunnel in soft clay. Tunn Undergr Sp Technol 24(4):472–481

Zhang F, Gao Y, Wu Y, Wang Z (2018) Face stability analysis of large-diameter slurry shield-driven tunnels with linearly increasing undrained strength. Tunn Undergr Sp Technol 78:178–187

Zhou F, Hu X, Meng Q (2015) Model and method of permeability evaluation based on mud invasion effects. Appl Geophys 4:482–492

Zumsteg R, Puzrin A, Anagnostou G (2016) Effects of slurry on stickiness of excavated clays and clogging of equipment in fluid supported excavations. Tunn Undergr Sp Technol 58:197–208

Zhang K, Zhou J, Zhang L, Jiang T, Xia P, Wang Z (2014) Cake thickness measurement method based on formation testing. CN 104196525A (in Chinese)

Thewes M, Hollmann F (2016) Assessment of clay soils and clay-rich rock for clogging of TBMs. Tunn Undergr Sp Technol 57:122–128

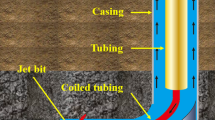

Liao H, Li G, Li J (2012) Flow field study on integrating straight and swirling jets for radial horizontal drilling. J China Coal Soc 37(11):1895–1900

Li J, Song W, Xing Y (2008) Influences of geometric parameters upon nozzle performances in scramjets. Chin J Aeronaut 6:30–35

Acknowledgements

The work was financially supported by the Science and Technology Major Project of Hunan Province, China (Grant No. 2014FJ1002), and the Science and Technology Project of States Grid Corporation of China (Grant No. JSJS1600326).

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Daniel Onofre de Almeida Cruz, D.Sc.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiao, X., Xia, Y., Mao, X. et al. Effect of the nozzle structure of the large-diameter slurry shield cutterhead on the scouring characteristics. J Braz. Soc. Mech. Sci. Eng. 42, 157 (2020). https://doi.org/10.1007/s40430-020-2255-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-2255-0