Abstract

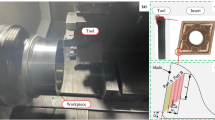

In this study, the effects of microscale textures on a sapphire cutting tool were investigated. The texturing of microscale features on a solid surface allowed control of the tribological characteristics of the tool surface. Microscale geometrical characteristics on the rake face of the sapphire tools were obtained through micro-abrasive blasting. Tribological tests and cutting tests on an aluminum alloy workpiece were carried out, and the cutting forces were measured and analyzed. The effect of texture on adhesion of work material was investigated. Results showed that friction was minimized and cutting forces at the tool-chip interface of the textured tool were significantly reduced from those of a conventional tool. It was observed that the adhesion of work material was reduced by applying texture on the tool rake face.

Similar content being viewed by others

References

Koshy, P. and Tovey, J., “Performance of Electrical Discharge Textured Cutting Tools,” CIRP Annals-Manufacturing Technology, Vol. 60, No. 1, pp. 153–156, 2011.

Deng, J., Lian, Y., Wu, Z., and Xing, Y., “Performance of Femtosecond Laser-Textured Cutting Tools Deposited with WS2 Solid Lubricant Coatings,” Surface and Coatings Technology, Vol. 222, pp. 135–143, 2013.

Jianxin, D., Ze, W., Yunsong, L., Ting, Q., and Jie, C., “Performance of Carbide Tools with Textured Rake-Face Filled with Solid Lubricants in Dry Cutting Processes,” International Journal of Refractory Metals and Hard Materials, Vol. 30, No. 1, pp. 164–172, 2012.

Kawasegi, N., Sugimori, H., Morimoto, H., Morita, N., and Hori, I., “Development of Cutting Tools with Microscale and Nanoscale Textures to Improve Frictional Behavior,” Precision Engineering, Vol. 33, No. 3, pp. 248–254, 2009.

Byun, J. W., Shin, H. S., Kwon, M. H., Kim, B. H., and Chu, C. N., “Surface Texturing by Micro ECM for Friction Reduction,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 5, pp. 747–753, 2010.

Choi, Y. and Lee, J., “A Study on the Effects of Surface Dimple Geometry on Fretting Fatigue Performance,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 4, pp. 707–713, 2015.

Xu, S., An, S. O. J., Atsushi, D., and Castagne, S., “Development of Low-Cost Deformation-Based Micro Surface Texturing System for Friction Reduction,” Int. J. Precis. Eng. Manuf., Vol. 17, No. 8, pp. 1059–1065, 2016.

Kümmel, J., Braun, D., Gibmeier, J., Schneider, J., Greiner, C., et al., “Study on Micro Texturing of Uncoated Cemented Carbide Cutting Tools for Wear Improvement and Built-Up Edge Stabilisation,” Journal of Materials Processing Technology, Vol. 215, pp. 62–70, 2015.

Ling, T. D., Liu, P., Xiong, S., Grzina, D., Cao, J., et al., “Surface Texturing of Drill Bits for Adhesion Reduction and Tool Life Enhancement,” Tribology Letters, Vol. 52, No. 1, pp. 113–122, 2013.

Sugihara, T. and Enomoto, T., “Improving Anti-Adhesion in Aluminum Alloy Cutting by Micro Stripe Texture,” Precision Engineering, Vol. 36, No. 2, pp. 229–237, 2012.

Varun, S. and Pulak, M. P., “Geometrical Design Optimization of Hybrid Textured Self-Lubricating Cutting Inserts for Turning 4340 Hardened Steel,” The International Journal of Advanced Manufacturing Technology, Vol. 89, No. 5, pp. 1575–1589, 2015.

Xie, J., Luo, M.-J., He, J.-L., Liu, X.-R., and Tan, T.-W., “Icro-Grinding of Micro-Groove Array on Tool Rake Surface for Dry Cutting of Titanium Alloy,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 10, pp. 1845–1852, 2012.

Graham, E., Park, C. I., and Park, S. S., “Fabrication of Micro-Dimpled Surfaces through Micro Ball End Milling,” Int. J. Precis. Eng. Manuf., Vol. 14, No. 9, pp. 1637–1646, 2013.

Wang, Y. Q., Yang, H. F., Han, Q. G., Fang, L., and Ge, S. R., “Tribological and Lubrication Properties of Sandblast-Textured Surfaces with Varied Roughness,” Advanced Materials Research, Vols. 154-155, pp. 1019–1022, 2011.

Oishi, K., “Mirror Cutting of Aluminum with Sapphire Tool," Journal of Materials Processing Technology, Vol. 62, No. 4, pp. 331–334, 1996.

Verdaasdonk, R. M., Cross, F. W., and Borst, C., “Physical Properties of Sapphire Fibretips for Laser Angioplasty,” Lasers in Medical Science, Vol. 2, No. 3, pp. 183–188, 1987.

Obikawa, T., Kamio, A., Takaoka, H., and Osada, A., “Micro-Texture at the Coated Tool Face for High Performance Cutting,” International Journal of Machine Tools and Manufacture, Vol. 51, No. 12, pp. 966–972, 2011.

Lei, S., Devarajan, S., and Chang, Z., “A Study of Micropool Lubricated Cutting Tool in Machining of Mild Steel,” Journal of Materials Processing Technology, Vol. 209, No. 3, pp. 1612–1620, 2009.

Yu, H., Deng, H., Huang, W., and Wang, X., “The Effect of Dimple Shapes on Friction of Parallel Surfaces,” Proc. of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, Vol. 225, No. 8, pp. 693–703, 2011.

Childs, T., “Metal Machining: Theory and Applications,” Butterworth-Heinemann, 2000.

Williams, J., “The Action of Lubricants in Metal Cutting,” Journal of Mechanical Engineering Science, Vol. 19, No. 5, pp. 202–212, 1977.

Kovalchenko, A., Ajayi, O., Erdemir, A., Fenske, G., and Etsion, I., “The Effect of Laser Surface Texturing on Transitions in Lubrication Regimes during Unidirectional Sliding Contact,” Tribology International, Vol. 38, No. 3, pp. 219–225, 2005.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, Y., Kim, MR., Lee, DW. et al. Effects of micro textured sapphire tool regarding cutting forces in turning operations. Int. J. of Precis. Eng. and Manuf.-Green Tech. 4, 141–147 (2017). https://doi.org/10.1007/s40684-017-0017-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-017-0017-y