Abstract

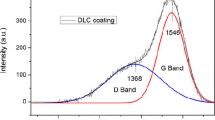

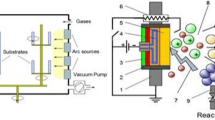

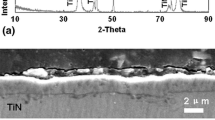

The ceramic and carbon coatings such as titanium nitride (TiN) and diamond-like carbon (DLC) coatings are characterised by good mechanical properties and chemical inertia. The objective of this work is to compare the wear, friction, adhesion and corrosion behaviour of commercial TiN and DLC coatings deposited on AISI 420 stainless steel, by plasma-assisted techniques. The microstructure of the coatings was characterised by optical and electronic microscopy and X-ray diffraction. The hardness and Young’s modulus were measured by nanoindentation. Pin-on-disk, fretting and abrasive wear tests were performed. Adhesion was evaluated by means of Scratch Test and Rockwell C Indentation. The corrosion behaviour was evaluated by Salt Spray Fog and electrochemical tests in chloride solutions. The thickness of both coatings was between 1 and 1.5 µm. The hardness was 26 GPa and 34 GPa for DLC and TiN coating, respectively. The results showed that the TiN coatings presented better abrasive wear resistance than the DLC coatings; however, the latter was more resistant to the pin-on-disk test, fretting and it had a lower friction coefficient. Both coatings showed far better wear resistance than the untreated steel. Finally, TiN coatings had better adhesion to the substrate than DLC coatings, proved in both tests. Regarding the corrosion behaviour, both coatings exhibited acceptable corrosion resistance in the Salt Spray Fog Test, but only the DLC coatings had both nobler corrosion potential and higher breakdown potential than the TiN coatings in electrochemical tests.

Similar content being viewed by others

References

Xi Y, Liu D, Han D (2008) Improvement of corrosion and wear resistances of AISI 420 martensitic stainless steel using plasma nitriding at low temperature. Surf Coat Technol 202(12):2577–2583. https://doi.org/10.1016/j.surfCoat2007.09.036

Davis JR (2002) Surface hardening of steels. ASM International, Materials Park, OH

Wang C, Ou S, Chiou S (2014) Microstructures of TiN, TiAlN and TiAlVN coatings on AISI M2 steel deposited by magnetron reactive sputtering. Trans Nonferrous Met Soc China 24(8):2559–2565. https://doi.org/10.1016/S1003-6326(14)63383-5

Trava-Airoldi VJ, Bonetti LF, Capote G, Fernandes JA, Blando E, Hübler R et al (2007) DLC film properties obtained by a low cost and modified pulsed-DC discharge. Thin Solid Films 516(2–4):272–276. https://doi.org/10.1016/j.tsf.2007.06.100

Pieniak D, Pasierbiewicz K, Niewczas A (2017) Effect of mechanical properties of substrate and coating on wear performance of TiN- or DLC-coated 316LVM stainless steel. Wear 382–383:62–70. https://doi.org/10.1016/j.wear.2017.04.017

Cemin F, Bim LT, Menezes CM, Maia MEH, Baumvol IJR, Alvarez F et al (2015) The influence of different silicon adhesion interlayers on the tribological behavior of DLC thin films deposited on steel by EC-PECVD. Surf Coat Technol 283:115–121. https://doi.org/10.1016/j.surfCoat2015.10.031

Naghibi SA, Raeissi K, Fathi MH (2014) Corrosion and tribocorrosion behavior of Ti/TiN PVD coating on 316L stainless steel substrate in Ringer’s solution. Mater Chem Phys 148(3):614–623. https://doi.org/10.1016/j.matchemphys.2014.08.025S.A

Capote G, Bonetti LF, Santos LV, Trava-airoldi VJ (2008) Adherent amorphous hydrogenated carbon films on metals deposited by plasma enhanced chemical vapor deposition. Thin Solid Films 516(12):4011–4017. https://doi.org/10.1016/j.tsf.2007.08.007

Hadinata S, Lee M, Pan S, Tsai W (2013) Electrochemical performances of diamond-like carbon coatings on carbon steel, stainless steel, and brass. Thin Solid Films 529:412–416. https://doi.org/10.1016/j.tsf.2012.05.041

Zuo J, Xie Y, Zhang J, Wei Q, Zhou B, Luo J et al (2015) TiN coated stainless steel bracket: tribological, corrosion resistance, biocompatibility and mechanical performance. Surf Coat Technol 277:227–233. https://doi.org/10.1016/j.surfCoat2015.07.009

Quan Z, Wu P, Tang L, Celis J (2006) Corrosion-wear monitoring of TiN coated AISI 316 stainless steel by electrochemical noise measurements. Appl Surf Sci 253:1194–1197. https://doi.org/10.1016/j.apsusc.2006.01.062

Azzi M, Amirault P, Paquette M, Klemberg-Sapieha JE, Martinu L (2010) Corrosion performance and mechanical stability of 316L/DLC coating system: role of interlayers. Surf Coat Technol 204(24):3986–3994. https://doi.org/10.1016/j.surfcoat.2010.05.004

Santana Da Silva PC, Ramirez Ramos MA, Corat EJ, Trava-Airoldi VJ (2016) DLC films grown on steel using an innovator active screen system for PECVD technique. Mater Res 19(4):882–888. https://doi.org/10.1590/1980-5373-MR-2015-0456

Lugo DC, Silva PC, Ramirez MA, Pillaca EJDM, Rodrigues CL, Fukumasu NK, Corat EJ, Tabacniks MH, Trava-Airoldi VJ (2017) Characterization and tribologic study in high vacuum of hydrogenated DLC films deposited using pulsed DC PECVD system for space applications. Surf Coat Technol 332:135–141. https://doi.org/10.1016/j.surfcoat.2017.07.084

Shan L, Wang Y, Li J, Li H, Wu X, Chen J (2013) Tribological behaviours of PVD TiN and TiCN coatings in artificial seawater. Surf Coat Technol 226:40–50. https://doi.org/10.1016/j.surfCoat2013.03.034

Dalibon EL, Trava-airoldi V, Pereira LA, Cabo A, Brühl SP (2014) Wear resistance of nitrided and DLC coated PH stainless steel. Surf Coat Technol 255:22–27. https://doi.org/10.1016/j.surfcoat.2013.11.004

Ferrari AC, Robertson J (2000) Interpretation of Raman spectra of disordered and amorphous carbon. Phys Rev B 61(20):14095–14107. https://doi.org/10.1103/PhysRevB.61.14095

Casiraghi C, Ferrari AC, Robertson J (2005) Raman spectroscopy of hydrogenated amorphous carbons. Phys Rev B 72:085401–085414. https://doi.org/10.1103/PhysRevB.72.085401

Jedrzejowski P, Klemberg-Sapieha JE, Martinu L (2003) Relationship between the mechanical properties and the microstructure of nanocomposite TiN/SiN1.3 coatings prepared by low temperature plasma enhanced chemical vapor deposition. Thin Solid Films 426(1–2):150–159. https://doi.org/10.1016/S0040-6090(03)00028-2

Robertson J (2002) Diamond-like amorphous carbon. Mater Sci Eng R 37(4–6):129–281. https://doi.org/10.1016/S0927-796X(02)00005-0

Donnet C, Erdemir A (2008) Tribology of diamond-like carbon films. Fundamentals and applications. Springer, Boston

Grill A (1997) Tribology of diamondlike carbon and related materials: an updated review. Surf Coat Technol 94–95:507–513. https://doi.org/10.1016/S0257-8972(97)00458-1

Foerster CE, Serbena FC, da Silva SLR, Lepienski CM, Siqueira CJ, de M, Ueda M (2007) Mechanical and tribological properties of AISI 304 stainless steel nitrided by glow discharge compared to ion implantation and plasma immersion ion implantation. Nucl Instrum Methods Phys Res B 257(1–2):732–736. https://doi.org/10.1016/j.nimb.2007.01.266

Kakaš D, Terek P, Miletić A, Kovačević L, Vilotić M, Škorić B, Krumes D (2013) Friction and wear of low temperature deposited TiN coating sliding in dry conditions at various speeds. Tehnički Vjesnik 20(1):27–33

Hutchings IM (2001) Tribology, friction and wear of engineering materials. Butterworth-Heinemann Ltd, London

Sawase T, Yoshida K, Taira Y, Kamada K, Atsuta M, Baba K (2005) Abrasion resistance of titanium nitride coatings formed on titanium by ion-beam-assisted deposition. J Oral Rehabil 32(2):151–157. https://doi.org/10.1111/j.1365-2842.2004.01382.x

Vidakis N, Antoniadis A, Bilalis N (2003) The VDI 3198 indentation test evaluation of a reliable qualitative control for layered compounds. J Mater Process Technol 143–144:481–485. https://doi.org/10.1016/S0924-0136(03)00300-5

Holmberg K, Matthews A (2009) Coatings tribology properties, mechanisms, techniques and applications in surface engineering. Elsevier, Amsterdam

Holmberg K, Ronkainen H, Laukkanen A, Wallin K, Erdemir A, Eryilmaz O (2006) Tribological analysis of TiN and DLC coated contacts by 3D FEM modelling and stress simulation. Wear 264(9–10):877–884. https://doi.org/10.1016/j.wear.2006.12.084

Sveen S, Andersson JM, Saoubi RM, Olsson M (2013) Scratch adhesion characteristics of PVD TiAlN deposited on high speed steel, cemented carbide and PCBN substrates. Wear 308(1–2):133–141. https://doi.org/10.1016/j.wear.2013.08.025

Grill A (1998) Diamond-like carbon: state of the art. Diam Relat Mater 8(2–5):428–434. https://doi.org/10.1016/S0925-9635(98)00262-3

Acknowledgements

The authors would like to thank Dr. Sebastian Suarez (Saarland University, Saarbrücken, Germany) for the SEM-FIB analysis, Soledad Pereda (INTI, Mecánica) for the use of SEM and Vanesa Fuchs (INTEMA) for XRD measurements. The study was supported by Universidad Tecnológica Nacional (Grant No. MAUTNCU0003884).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dalibón, E.L., Pecina, J.N., Moscatelli, M.N. et al. Mechanical and Corrosion Behaviour of DLC and TiN Coatings Deposited on Martensitic Stainless Steel. J Bio Tribo Corros 5, 34 (2019). https://doi.org/10.1007/s40735-019-0228-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-019-0228-6