Abstract

Here, we provide a status update of an integrated gasification fuel cell (IGFC) power-generation system being developed at the National Institute of Clean-and-Low-Carbon in China at the megawatt thermal (MWth) scale. This system is designed to use coal as fuel to produce syngas as a first step, similar to that employed for the integrated gasification combined cycle. Subsequently, the solid-oxide fuel-cell (SOFC) system is used to convert chemical energy to electricity directly through an electrochemical reaction without combustion. This system leads to higher efficiency as compared with that from a traditional coal-fired power plant. The unreacted fuel in the SOFC system is transported to an oxygen-combustor to be converted to steam and carbon dioxide (CO2). Through a heat-recovery system, the steam is condensed and removed, and CO2 is enriched and captured for sequestration or utilization. Comprehensive economic analyses for a typical IGFC system was performed and the results were compared with those for a supercritical pulverized coal-fired power plant. The SOFC stacks selected for IGFC development were tested and qualified under hydrogen and simulated coal syngas fuel. Experimental results using SOFC stacks and thermodynamic analyses indicated that the control of hydrogen/CO ratio of syngas and steam/CO ratio is important to avoid carbon deposition with the fuel pipe. A 20-kW SOFC unit is under development with design power output of 20 kW and DC efficiency of 50.41%. A 100 kW-level subsystem will consist of 6 × 20-kW power-generation units, and the MWth IGFC system will consist of 5 × 100 kW-level subsystems.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Coal-fired power plants provide most of the electricity needs in China. Coal is used because China has vast coal reserves and its low cost. Unfortunately, the carbon dioxide (CO2) produced by such plants is a major source of CO2 emission and air pollution. In 2019, China’s CO2 emission was more than the sum of that produced by Europe and the USA. In the Paris Agreement signed by international leaders in 2015, the Chinese government promised that CO2 emission in China would peak in 2035 and then decrease gradually to < 3 gigatons (Gt) by 2050, compared with 9 Gt in 2015 (Jiang 2017). CHN Energy is one of the leading energy companies in China. It ranks 107 in the top-500 companies worldwide. The coal mining of CHN Energy is up to 500 million metric tons per year. The total electricity generated by a coal-fired power plant is 190 gigawatts per year, about 45% of total electricity by CHN Energy. Old coal-fired power plants have lower efficiency (up to 35%–40%) and also generate significant CO2 emission as well as other contaminants (e.g., nitric oxides, sulfur dioxide, and dust) to cause air pollution. A supercritical pulverized coal (SCPC) power plant has better efficiency (≤ 48%) but its cost is higher if CO2 is captured and stored.

Integrated gasification combined cycle (IGCC) and integrated gasification fuel cell (IGFC) power-generation systems with CO2 capture have been developed recently to use coal effectively and to reduce air pollution and CO2 emission. Compared with IGCC, IGFC is more efficient and incurs an lower overall cost, especially for pressurized systems (Braun et al. 2012). IGFC is expected to be the most efficient power-generation system in coal-fired power-generation systems (Liese et al. 2010; Ghosh et al. 2006). A typical IGFC power-generation system comprises: (1) a coal-gasification subsystem to convert coal powder to syngas and remove all impurities; (2) high-temperature solid-oxide fuel-cell system (SOFC); (3) a subsystem for the capture, utilization, and storage of CO2. A simple IGFC system is similar to an IGCC system, but the gas turbine power island is replaced by a fuel cell power module. The fuel cell is a device to convert chemical energy to electricity through an electrochemical reaction. Hence, more efficient power generation can be achieved using IGFC than that using IGCC. The numerical simulation, by the National Institute of Advanced Industrial Science and Technology in Japan (Nomura et al. 2011), indicated that, power-generation efficiency of 64.5% (HHV) and 53.6% (HHV) could be achieved using high-grade bituminous coal under ideal conditions and low-grade coal, i.e., lignite and subbituminous coal, respectively. Developing an IGFC power-generation system to convert old coal-fired power plants to “green energy” to reduce CO2 emission and air pollution significantly is an urgent task for CHN Energy. Since July 2017, the National Institute of Clean-and-Low-Carbon Energy (NICE), which is fully owned by China Energy, has been developing an IGFC demonstration system working with key partners: Huaneng Clean Energy Research Institute, China University of Mining Technology, and Huaqing Inc. High-quality coal syngas is being mass-produced at a coal-to-oil plant in Yinchuan (Ningxia Province, China) by a subsidiary of CHN Energy. This coal syngas will be used as fuel for the IGFC system being developed by NICE. Therefore, the purification processes for coal gasification and coal syngas will not be discussed here. Oxygen combustion of exhaust fuel from the fuel-cell system and CO2 capture will be discussed in a separate study (Wang 2021). The development status of the high-temperature SOFC power-generation system, including the system design and initial experimental results, are presented and discussed here.

2 Economic analyses of the IGFC system

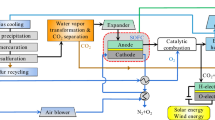

First, comprehensive economic analyses for a typical IGFC system mentioned in the USA Department of Energy National Energy Technology Laboratory (DOE NETL) report (DOE/NETL 2014) were performed. This IGFC system consists of three main subsystems: (1) coal gasification and removal of various impurities; (2) SOFC power-generation subsystem with anode loop recycling; (3) an oxygen combustion and heat recovery system generation for CO2 capture [Fig. 1; adapted from DOE/NETL reports (DOE/NETL 2014, 2015)]. An ASPEN Plus model was built to estimate the costs for Case 1.1 and Case 2.1 in the DOE NETL report using a cost of production (CoP) gasifier. The assumptions and parameters used in the model are listed in Table 1. Costing methods were used from various references. First, IGCC with a CoP gasifier without CO2 capture (Case B4A) was used for cost estimates for most non-SOFC components. Case B5A was employed to evaluate the costs of the Selexol plant and adapt them for IGFC costing cases. Case 12F was used for estimating cryogenic separation of CO2 from other components (DOE/NETL 2015). The Quality Guidelines for Energy System Studies (QGESS) capital cost scaling methodology was employed for scaling the components to the size estimated for the IGFC cases (DOE/NETL 2013). The USA estimates were converted to Chinese renminbi using a conversion rate of USD: RMB of 1:6.5. Figure 2 shows a comparison of several cases. We have reported the estimates for SCPC and SCPC with CO2 capture previously (Surinder 2018). The SCPC study was used to calculate the factors that could reduce the capital cost and operating cost between the USA and China. These factors were used to update the IGFC cases in the USA to calculate the IGFC costs in China. This is a simplified methodology for calculating IGFC costs in China. A more detailed analysis is suggested for an additional study in which each unit operation is modeled and sized specifically for Chinese conditions. Such work is outside the scope of the present study. The Base IGFC case was modeled versus Case 1.1 in the DOE study with an SOFC degradation rate of 1.5%/1000 h. The lower degradation rate case was modeled according to Case 1.2 of the DOE study with an SOFC degradation rate of 0.2%/1000 h. The advanced IGFC case was modeled according to Case 3.1 in the DOE study at a pressure of 8 bars instead of 20 bars used in the DOE study. A capacity factor of 80% was chosen for Case 1.1, 1.2, CN 1.1 and CN 1.2 and 85% for Case 3.1 and CN 3.1 for comparison with DOE NETL cases. The results are shown in Fig. 2. Comparison of different cases revealed that China-based systems were consistently lower in cost compared with those in the USA. IGFC costs were higher compared to SCPC without and with CO2 capture at an SOFC degradation rate of 1.5%/1000 h. The IGFC system could become competitive compared with SCPC with CO2 capture if the SOFC degradation rate could be reduced to 0.2%/1000 h. Such SOFC technology has been demonstrated at 250 kW in the USA and Japan (Kobayashi 2015). The IGFC system at higher pressure indicates a further reduction in cost of electricity (COE).

A typical IGFC system for economic analysis (from DOE/NETL report, 2014)

3 Development of an IGFC system

3.1 Selection and evaluation of SOFC stacks

CHN Energy is a traditional energy company. It has focused mainly on coal mining, coal-fired power plants, wind power, hydropower, and solar power in recent years: SOFC technology is not available in-house. We communicated with several domestic and international SOFC developers to obtain high-quality and low-cost stacks for this program. Based on quality, availability, cost, as well as mass-production capability and quality control, the stacks from Elcogen in Finland, Sanhuan in Chaozhou (China), Huaqing in Suzhou (China), and China University of Mining and Technology (Beijing) were considered for evaluation. Leakage was inspected for all incoming stacks, and followed by electrochemical testing using hydrogen fuel at 700–800 °C at ambient pressure based on stack specifications provided by the suppliers. More testing data from Sanhuan stacks were generated due to their availability. All testing stands/systems used for testing of SOFC stacks or modules in this work were designed and built by NICE with suppliers. Figure 3 summarizes the testing results (stack voltage and power output versus current density) of three individual stacks. For stack 1, the stack power output was 981 W at a current density of 250 mA/cm2, and increased to 1021 W at a current density of 270 mA/cm2. If the current density was > 270 mA/cm2, the stack voltage formed a tail, which was off the trend line. To better understand the effect of testing conditions on stack performance, the stack was tested under different fuel flow rates and all tests were done at 750 °C (stack 2 and 3 in Fig. 3). When the flow rate was increased from 9 standard liters per minute (SLPM) for stack 1- to 12 SLM for stack 2, and 13 SLPM for stack 3, the stack voltage showed good linearity.

The testing data of stack 1 were analyzed further to better understand the stack properties [e.g., area specific resistance (ASR, ohm-cm2)] and stack performance (e.g., fuel utilization and DC power efficiency) under different testing conditions. The electrochemical reaction on the anode side can be expressed as:

Fuel utilization during stack operation is based on the fuel consumed by the electrochemical reaction divided by total inlet fuel to the stack, and can be written as Eq. (2) using hydrogen fuel as an example:

where, I is the current through the fuel cell stack (ampere); F is the Faraday’s constant (C/mol); n is the number of cells connected in series in the stack; qv H2 is the hydrogen flow rate (L/s); Vm is the molar volume of a gas at standard conditions (L/mol). The DC power efficiency of the SOFC stack or module can be obtained by Eq. (3):

where, P is the stack power output (W); qmol is the fuel flow rate (mol/s); Q is the low heat value of the inlet fuel (J/mol) whereby Q = 285,800 J/mol for hydrogen.

Figure 4 summarizes the average stack ASR, fuel utilization, and DC power efficiency vs. current density at an average temperature of 750 °C with fixed fuel (9 SLPM) and air flow (25 SLPM) rates. At a current density of 250 mA/cm2, the stack average ASR, fuel utilization, and DC power efficiency were 0.305 Ω cm2, 82.7%, and 61.3%, respectively. Upon increasing the current density from 250 to 270 mA/cm2, the stack average ASR, fuel utilization, and DC efficiency increased to 0.420 Ω cm2, 90.7%, and 63.4%, respectively, and a tail started to form from the voltage vs. current density curve (Fig. 3). Most likely fuel starvation occurred in a local area within the stack (especially near the stack outlet) when the current density was ≥ 270 mA/cm2 with a fuel flow rate of 9 SLPM. In general (as expected), the ASR curve showed three distinct regions. At a low current density, the cell potential dropped as a result of activation polarization. Steam has a significant effect on anode polarization (e.g., hydrogen absorption and dissociation on Ni particles) and the charge can be transferred easier under an electric field. Hence, stack ASR decreased significantly with increasing current density (hydrogen fuel is pure hydrogen and the steam content in the fuel increased with increasing current density). At moderate current densities, the cell potential decreases linearly with current due to ohmic losses. Therefore, stack ASR showed almost no change with current density at 0.10–0.25 A/cm2. At high current densities (> 0.25 A/cm2), the decrease in cell potential departs from a linear relationship with current density as a result of more pronounced concentration polarization. Operating the Sanhuan stack at a current density of ~ 250 mA or fuel utilization of ~ 80% appeared to be safe.

Short-term stack durability was tested ≤ 540 h under different conditions (Fig. 5). In period one, the fuel flow and air flow was 13 SLPM and 36 SLPM, respectively, and then the fuel flow was reduced to 10.6 SLPM while keeping air flow constant in period 2. Within both periods, stack degradation was observed. In period 3, air flow was increased to 69 SLPM while the fuel flow was unchanged. In period 4, the stack current was decreased from 24 to 22 A, and back to 24 A for period 5. Stack degradation trend was not noticeable for periods 3–5 even though the duration is not long enough.

3.2 Operating conditions for the designed system

The IGFC system being developed will be operated under coal syngas rather than hydrogen fuel. Therefore, the stack performance under coal syngas must be evaluated and the operating conditions for the designed system must be defined. The composition of coal syngas available for operation of the IGFC system is approximately 61.8% H2, 36.7% CO, and 1.1% N2 with a minor content of CO2 and CH4. Based on thermodynamics, carbon monoxide (CO) tends to form carbon under certain conditions: “reverse Boudouard reaction” (Eq. (4)). This is an exothermal reaction and is thermodynamically favored at < 500 °C based on thermodynamic analyses (Fig. 6). The carbon formed can be deposited on the inner surface of the fuel pipe to block the fuel flow channel or enter the stack with fuel gas stream and be deposited on the anode surface. The stack performance would be affected under either case. The contact material and properties of the material surface can also affect carbon formation. The amount of carbon formation at different temperatures was analyzed using ASPEN Plus for the syngas with different H2/CO ratio in the syngas (Fig. 6a–c). When H2/CO ratio is 1.68 (61.8% H, 37.7% CO), the high end temperature for carbon formation was decreased from about 400 °C to 300 °C with increasing steam/CO ratio from 1 to 1.15. When the H2/CO ratio was 2.3 (69.7% H2, 30.3% CO), the high-end temperature for carbon formation changed to ~ 200 °C and the steam/CO ratio, when changing from 0.8 to 1.0, showed no significant effect on the carbon-formation temperature (which is determined by the thermodynamics of the reaction). Above this temperature, the change in the Gibbs free energy of reactions (4), G, is positive and the reaction would not occur. If the H2/CO ratio was increased further to 2.9 (74.4% H2, 25.6% CO), the highest temperature for carbon formation would decrease to ~ 150 °C even without steam addition. From a kinetics view point, the reaction speed would be too slow at lower temperatures and reaction (4) may not occur because the fuel gas stream will pass this temperature range at high speed (~ 14 SLPM) under the operating conditions of the system.

Stack testing was also done to better understand its performance and behavior under coal syngas (Fig. 7). To ensure that this specific stack had the same performance as that of the other stacks under hydrogen, the stack was tested first under hydrogen at a flow rate of 13 SLPM at 750 °C. The V/j curve (V_1st H2) showed good linearity, and the stack generated 1252 W (P_1st H2) at a current density of 330 mA/cm2, which indicated a good stack. Then, the fuel was switched to simulated coal syngas with a composition of 61.8% H2 and 37.7% CO (steam/CO ratio was 1). The open circuit voltage (OCV) change was as expected due to the pO2 change in the fuel stream, and the V/j curve was linear up to a current density of 270 mA/cm2.

Above that current density, both the voltage curve and power curve tailed down from the trend line of the original plot. The test was shut-down for inspection. Significant deposition of carbon within the fuel inlet pipe was identified. The stack was reheated to 750 °C under a safe gas (5% H2 balanced with nitrogen), purged with hydrogen at 750 °C, and then tested again after the OCV had stabilized. The V/j curve of the second test under hydrogen (V_2nd H2), in general, overlapped with V_1st H2. Hence, the carbon damage to stack performance was temporary and recoverable if the fuel stream was switched from simulated syngas to hydrogen. Analyses of the test set-up after testing indicated that the steam was added to the fuel stream near the entrance of the furnace, where the temperature may have been much higher than the temperature range of carbon formation. Hence, carbon was possibly formed before the steam was added to the fuel inlet pipe.

A second stack test was undertaken at 725 °C (stack average temperature) using simulated coal syngas (61.8% H2, 37.7% CO, steam/CO ratio: ~ 0.7) as fuel to ensure that the steam was added to the fuel stream at a lower temperature before carbon could be formed. The stack performance was stable during testing. A series of tests were completed at current densities between 258.2 and 282.9 mA/cm2 with high voltage per cell (Table 2). A stack power of 1022 W and DC efficiency of 53.2% were achieved. Fuel utilization was ≤ 84.6% with no sign of fuel starvation. However, carbon was observed within the fuel inlet system during after-test inspection. This phenomenon may have been due to the lower steam/CO ratio or insufficient mixing between the fuel gas and steam.

After successful single-stack testing, a four-stack module was tested using pipeline coal syngas at the coal-to-oil plant in Yinchuan. During testing, the coal syngas was mixed with partial hydrogen to obtain a composition with a higher H2/CO ratio of 2.8 (72.9% H2, 26.0% CO, steam/CO ratio = 1). The module power generation, fuel utilization, and DC power efficiency were 1.4 kW/stack, 84.5%, and 53%, respectively. The module was operated under a mixture of coal syngas and hydrogen for ≤ 350 h without noticeable degradation. Post-test analyses showed no carbon deposition in the fuel pipeline. Detailed experimental results will be published separately (Xu 2021).

Based on thermodynamic analyses and performance-verification tests of the stack, a coal syngas composition with a H2/CO ratio from 1.68 to 2.8 could be used as fuel for an IGFC power-generation system. If the syngas had a lower H2/CO ratio, more steam would be required to mix with the coal syngas at > 100 °C and below the temperatures where carbon formation was thermodynamically favored within the surface of the fuel inlet pipeline to prevent carbon deposition, which could affect the system performance if the steam content was too high. If the coal syngas had a higher H2/CO ratio, carbon deposition could be prevented with less steam (or even no steam) in the fuel stream. More data on stack performance with a different composition of coal syngas and operating conditions are needed to achieve the highest power generation using the available coal syngas, or obtaining a coal-syngas composition which may benefit the power generation and efficiency of the IGFC system.

3.3 Development of a 20-kW SOFC power-generation unit

A simplified IGFC system flowchart is shown as Fig. 8 in which pipeline coal syngas is used. Sulfur is removed before the syngas enters into SOFC stacks. After an electrochemical reaction in the stack, outlet fuel (which contains about 10%–20% of flammable material) is fed into an oxygen-combustor to convert H2 into steam and CO into CO2. After passing through a heat-recovery system, steam is condensed and removed, and CO2 is enriched to > 95% for capture. Based on this flowchart, a 20-kW SOFC power-generation unit has been in development since April 2019 using the performance data of single-stack and four-stack modules obtained under hydrogen and simulated syngas or real coal syngas as fuel. The system process flow diagram is shown as Fig. 9. To clarify, this process flow diagram represents operation of the 20-kW power-generation unit under steady state. During system start-up or shut-down, a start-up gas burner will heat the system to the designed operating conditions or to provide extra heat during system shut-down to control the cooling rate. The fuel system comprises a mixing tank to thoroughly mix coal syngas and steam at > 100 °C to prevent carbon formation in the fuel inlet before entering the stack, and a heat exchanger to heat the fuel stream to the desired temperature (which is ~ 700 °C for the stack selected for our IGFC system). The fuel flow is single pass without recycling and the designed fuel utilization is 80%. The exhaust fuel, after cooling and separating the water from the gas stream, will be fed into an oxygen-combustor to burn the residual fuel and enrich CO2 > 95% for capture, which can be stored or utilized, such as producing H2-CO syngas through co-electrolysis of CO2 and steam. The detailed experimental results will be published separately (Wang 2021). The stack module contains four stack towers. Each tower was built from four stacks, which can generate a maximum power of ~ 20 kW under a current density of 336 mA/cm2 and 171.2 V/stack tower, respectively.

During a long-term steady-state operation, the module was designed to operate at 0.25 A/cm2 and the power output was 15 kW (Table 3). Computational fluid dynamics (CFD) simulation was conducted to better understand the fuel flow and air flow within the stack module because they are important for heat management and keeping a healthy stack during operation. The simulation results were promising (Fig. 10). The air flow was quite uniform and the variation in fuel flow was within ± 5%, which is acceptable for the system operation under design conditions. Uniform fuel flow will ensure no fuel starvation in any local area within the stack during system operation. Such uniform air flow could ensure that the temperature difference of all stacks in the module can be controlled within specifications. That is, the air inlet temperature of each stack will be 700 °C and outlet temperature will be ≤ 800 °C to maintain optimal performance and a healthy stack. The cathode loop consists of a gas start-up burner, and the hot exhaust gas can be used to heat up cold air if the system starts at room temperature. During steady operation of the system, the inlet air is heated through a heat exchanger. Figure 11 is the assembly sketch of the 20-kW SOFC power-generation system without the oxygen-combustor. On the back of the sketch, a hotbox shows where the SOFC module is installed. The hotbox is designed to keep the fuel cell module at constant temperature during steady-state operation via selection of insulation material to minimize heat loss and control the gas flow rate through the cathode loop. The front part is the balance of plant (BOP), including fuel, air, and safe gas (to protect the SOFC module during emergency shutdown), pipe line, control valves, flow meters, pressure meters, inlet fuel, air preheaters, exhaust fuel, and air blowers. The corner box is the control system. There is no external reformer and most CO in the fuel gas stream will be converted to CO2 within the fuel cell stack. This reaction is exothermal, and the released heat may help self-sustainable operation of the system. However, the temperature difference between the cathode inlet and outlet will be monitored closely to ensure the outlet temperature is ≤ 800 °C.

3.4 Conceptual design of a megawatt thermal (MWth) IGFC system

The conceptual design of a 500-kW IGFC power-generation system is shown in Fig. 12. The system consists of 5 × 100 kW-level subsystems which can be controlled separately, and the generated DC power is converted to AC power. There are 5–6 SOFC modules within each subsystem, which are connected electrically in parallel. If a module malfunctions or needs maintenance, other modules will not be affected and can continue to generate power. There are multiple stack towers within each module. These stack towers are connected electrically in parallel. In each stack tower, an individual stack is connected electrically in series.

The beauty of this design is that any damage, repair, or maintenance of individual stack tower, module, or subsystem will not affect operation of the other stack towers, modules, or subsystem. Based on Table 3, the design voltage of the stack tower during steady-state operation is 172.2 V. This voltage may be too low for direct DC/AC conversion; boosting to a higher DC voltage before conversion to AC power may be required. The desired DC voltage is dependent on the technology of the advanced DC/AC converter. The small amount of power loss through each DC booster and AC converter during system design will be considered.

The layout sketch of a 100 kW-level SOFC power-generation system is shown as Fig. 13. It consists of 6 × 20-kW fuel cell modules. Each module can generate 15-kW DC power during steady-state operation. All SOFC modules (including the hotbox) are located on one side of the layout, and the control system is located on another side. Gas pipe lines, heat exchangers, fuel preheaters, air preheaters, and blowers lie between them. The footprint of this 100 kW-level SOFC system is approximately 7 m × 30 m.

Based on the conceptual design and selected SOFC stacks, materials and key components of the BOP, the initial cost model of the 100 kW-level fuel cell system was established (Fig. 14). The stack cost was 30.4% which, in general, is the stack cost percentage in a SOFC power-generation system published by other developers of fuel cells. However, the stack cost may be slightly higher in our system because we purchased the stacks from the supplier and the labor cost for system assembly was counted in other cost rather than materials cost only. The heat exchanger was 7.9% and hotbox was 14.8%, which are expected to be reduced significantly because it is a customized design and built in very small quantities. Upon mass production, it will become a standard product and the cost will be much lower. The major cost seems to be related to the BOP: gas-pipe materials; gas flow and pressure control meters; fuel and air preheaters or burner during system start-up; heat exchangers during system steady-state operation; blowers to transport exhaust fuel to the oxygen-combustor to burn residual fuel to CO2 and steam for CO2 enrichment; labor cost for system assembly. It is a demonstration unit, so the overall cost is higher. For a commercial product, the system cost (including materials and labor) can be reduced significantly.

Each subsystem consists of 5–6 SOFC modules which are connected electrically in parallel.

4 Summary and conclusions

-

(1)

Economic analyses indicated that the advanced IGFC system (power degradation rate = 0.2%/1000 h or lower) with CO2 capture is competitive compared with SCPC, and its COE can be up to 20% lower than that of SCPC. Captured CO2 can be stored or utilized through co-electrolysis with H2O to produce syngas again to achieve fuel-electricity-waste fuel cycle.

-

(2)

Based on testing results, the SOFC stacks selected in our study showed good performance, consistency, and long-term stability. Average stack ASR was ~ 0.31 Ω-cm2 in hydrogen. Under preferred testing conditions, the stack did not show noticeable degradation during > 500 h of long-term durability testing in hydrogen fuel and coal syngas, which indicated a potential long service life. When using syngas as fuel, the H2/CO ratio and steam/CO ratio must be controlled to avoid carbon deposition within the fuel pipe. A H2/CO ratio of 1.68–2.8 and steam/CO ratio of 1 are acceptable. If the H2/CO ratio is low, the mixing of steam with syngas is important.

-

(3)

A 20-kW SOFC power-generation unit is being developed to verify technology feasibility. It consists of four stack towers. Each stack tower consists of 4 × 1–1.5-kW stacks, the power output of which is dependent on the fuel type and operating conditions. The maximum power output of the unit is expected to be 20 kW when using syngas as fuel. The CFD simulation of a 20-kW module indicates that fuel flow was, in general, uniform among 16 stacks. Flow variation between stacks was less than ± 5%. The 100 kW-level subsystem can be built by duplicating 5–6 × 20-kW power-generation units, and the MWth IGFC demonstration system (total input energy is MW and power output is 500 kW) will consist of 5 × 100 kW-level subsystems.

-

(4)

The operating conditions of the 20-kW power-generation unit, 100 kW-level subsystem, and the MWth IGFC demonstration system are a current density of 250 mA/cm2 (14.9 kW power output for steady-state operation) and 336 mA/cm2 (maximum 20-kW power output), respectively; fuel utilization of 80%, DC power efficiency of > 50%, stack inlet and outlet temperatures of 700 °C and 800 °C, respectively. DC voltage output from a SOFC stack tower will be > 171 V. A DC/DC booster may be required before DC/AC conversion.

Abbreviations

- ASR:

-

Area specific resistance (ohm cm2)

- BOP:

-

Balance of plant

- CFD:

-

Computational fluid dynamics

- COE:

-

Cost of electricity (CNY/MWh)

- DOE:

-

Department of Energy

- Eff:

-

Efficiency (%)

- QGESS:

-

Quality guidelines for Energy system studies

- IGCC:

-

Integrated gasification combined cycle

- IGFC:

-

Integrated gasification fuel cell

- j :

-

Current density (A/cm2)

- NETL:

-

National Energy Technology laboratory

- OCV:

-

Open circuit voltage (V)

- SLPM:

-

Standard liter per minute

- SCPC:

-

Supercritical pulverized coal

- SOFC:

-

Solid oxide fuel cell

- V:

-

Voltage (V)

References

Braun RJ, Kameswaran S, Yamanis J, Sun E (2012) Highly efficient IGFC hybrid power systems employing bottoming organic rankine cycles with optional carbon capture. J Eng Gas Turb Power 134:021801

DOE/NETL (2014) Techno-economic analysis of integrated gasification fuel cell systems created by energy sector planning and analysis for SEAP & OPPB/DOE/NETL-341/112613, November 24, 2014

DOE/NETL (2013) Capital cost scaling methodology quality guidelines for energy system studies DOE/NETL-341/013113

DOE/NETL (2015) Cost and performance baseline for fossil energy plants volume 1b: bituminous coal (IGCC) to electricity. DOE/NETL-2015/1727, July 31, 2015, Revision 2b-Year Dollar Update

Ghosh S, De S (2006) Energy analysis of a cogeneration plant using coal gasification and solid oxide fuel cell. Energy 31:345–363

Jiang X, Green C (2017) China’s future emission reduction challenge and implications for global climate policy. J Clim Policy 18:889–901

Kobayashi Y, Tomida K, Nishiura M, Hiwatashi K, Kishizawa H, Takenobu K (2015) Development of next-generation large-scale SOFC toward realization of a hydrogen society. Mitzubishi Heavy Ind Tech Rev 52:111–116

Liese E (2010) Comparison of preanode and postanode carbon dioxide separation for IGFC systems. J Eng Gas Turb Power 132:6

National Energy Technology Laboratory (2009) Integrated gasification fuel cell performance and cost assessment. DOE/NETL-2009/1361

National Energy Technology Laboratory (2013) Capital cost scaling methodology—quality guidelines for energy systems studies. DOE/NETL-341/013113

Nomura R, Ikl N, Kurata O, Kawabata M, Tsutsumi A, Koda E (2011) System analysis of IGFC with energy recuperation utilizing low-grade coal. In: Proceedings of ASME Turbo Expo GT2011, pp 1–9

Singh S et al (2018) China baseline coal-fired power plant with post-combustion CO2 capture: 2. Techno-economics. Int J Greenhouse Gas Cont 78:429–436

Wang HL, Xue YP, Yu SE, Li PP, Li CF (2021) Study on the combustion of exhaust fuel from the SOFC system fed with coal syngas in pure oxygen for CO2 capture. Int J Coal Sci Technol 8

Xu M, Wang HL, Li PP, Zhang ZH, Li CF (2021) Performance test and verification of SOFC stack module with coal syngas feeding. Int J Coal Sci Technol 8

Acknowledgements

The authors thank the Ministry of Science and Technology of the People’s Republic of China for financial support under contract of 2017YEB061900. The authors also want to thank China Energy and Shenhua New Energy Co., Ltd. for providing cost share; Ningxia Coal Industry Co., Ltd. for their support in establishing the electrochemical testing center and providing a site for the field test of the MWth IGFC system demonstration; and Professor Sun Yi at Harbin Institute of Technology for CFD simulation of stack module by his group. The discussion with Dr. Anthony Ku is helpful for putting together the section of economic analysis of the IGFC system.

Funding

Funding was provided by National Key R&D Program of China (2017YFB0601900).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wei, C., Liu, Z., Li, C. et al. Status of an MWth integrated gasification fuel cell power-generation system in China. Int J Coal Sci Technol 8, 401–411 (2021). https://doi.org/10.1007/s40789-021-00429-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40789-021-00429-1