Abstract

The problem of proper assessment of the technical functionality of rock bolt support systems is still valid. Many research centers have undertaken efforts to diagnose and monitor the technical state of such a support system used in mines and tunneling. With that aim the method of quality assessment of grouted rock bolts was invented and a relevant apparatus was constructed. The method concerns non-destructive identification of discontinuity of a resin layer (grout) surrounding rock bolts. The method is based on an impact excitation of a rock bolt and uses modal analysis procedures. Assuming that the installed rock bolt acts as an oscillator, different lengths and positions of grouting discontinuity alter its modal parameters. The extraction of these modal parameters, of which a resonant frequency is seen as the most valued, enable the relevant identification of grout discontinuity. After constructing a prototype version and validating the results for known cases of resin discontinuity in an experimental coal mine, the apparatus fulfilling ATEX requirements was developed. Subsequently that version was also verified both in laboratory conditions and in an experimental coal mine. As necessary for proper identification of discontinuity length, the reference data base was developed and elaborated consisting of a very large number of finite element models (FE models), namely discontinuity cases. The models encountered different rock bolt lengths and diameters, different rock strata parameters and different positions and lengths of resin layers. Then the method was used in a working coal mine to monitor a technical state of rock bolt support system mounted to reinforce long underground openings. The data base was utilized as reference for investigated rock bolts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

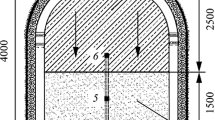

The rock bolt support systems are used to secure and reinforce the rock zone in the near field of an underground opening and to join it to deeper rock strata (Li Charlie 2010, 2017). Mostly steel rock bolts are used for that purpose (Tadollini 2010; Ulusay et al. 2007). The rock bolt consists of a steel bar grouted in an oversize hole. An installation machine is used to spin the bolt into the hole filled with fast setting epoxy resin cartridges. After hardening of the resin layer a plate and nut are driven up the bolt. Although robust resin cartridges are used, in mining practice the rock bolt may not be fully encapsulated as a consequence of various geotechnical conditions (Beard and Lowe 2003; Hebblewhite et al. 2003; Kidybiński et al. 2005): rock divergence, escape of grout into crevices, rock strata movement and improper grouting. The lack of proper grouting may be very hazardous, especially when the discontinuity is present at a deeper (hidden) part of a rock bolt, the examples shown in Fig. 1, and should be monitored (Haneol et al. 2019; Hartman et al. 2010).

Recent publications in the field of rock bolting, indicate that it is quite challenging to estimate the rock bolt integrity and grout quality with sufficient precision. With the aim of solving the problem different techniques and methods have been proposed like the methods which rely on excitation of a tested rock bolt to vibration along its axis of symmetry and the analysis of output signals, e.g. Granit (Ground Anchorage Testing Apparatus), Boltometer, RBT (Rock Bolt Testing) and others (Bačić et al. 2019; Bergman et al. 1983; Hartman et al. 2010; Knape 1988; Starkey et al. 2001, 2003). In a diagnosis process both acoustic and ultrasonic waves are utilized. Correspondingly, different analytical approaches are used as Fast Fourier Transform (FFT), wavelet transform analysis and neural network algorithms (Beard and Lowe 2003; Starkey et al. 2003; Hao et al. 2018; Patil and Maiti 2005; Sadettin 2007; Hyett et al. 2012). In order to observe the behavior of grouted rock bolts also smart sensors techniques are introduced (Gangbing et al. 2017), in particular load measurements at the heads (Hyett et al. 2012). But the problem is not fully resolved yet. The diagnosis of void spaces (regions of lack of bonding) is seen as crucial here. Accordingly, the method for non-destructive identification of grouting discontinuity of rock bolts is proposed to extend the diagnose scope in rock bolting. Though not known to the author at the experimental and analytical stages of the current work, it is very encouraging that a similar methodology to test the integrity of installed rock bolts, namely perpendicular direction of impact force, was presented over forty years ago by Godfrey (1977). However, the methodology was not implemented and modal testing was not proposed at that time.

The paper starts with a theoretical explanation of the relationships between investigated modal parameters and measured data. Then the method is presented. Subsequently it is shown how the method and apparatus fulfilling ATEX directives were validated in laboratory conditions and in an experimental coal mine (The acronym ATEX derives its name from: equipment intended for use in EXplosive ATmospheres). Finally, the results of the research realized in a working coal mine are discussed.

2 Materials and methods

2.1 Method and critical parameters

The proposed method, which uses modal analysis procedures, is based on an identification of natural frequencies of a rock bolt and an excitation is made in perpendicular direction to the symmetry axis of the tested object. For that purpose an impact hammer is used. An example of the test is presented in Fig. 2. The installed rock bolt acts as an oscillator, so different lengths and positions of grouting discontinuity alter its mechanical parameters: mass distribution, stiffness and damping which have their counterparts in the modal model as natural frequencies and modal vectors (shapes). Because each border condition (grout position and length) forms a unique response of the investigated structure, the extraction of these modal parameters enables the relevant identification of grout discontinuity. For that kind of test the diagnosis of bending modes seems to be more adequate than longitudinal modes as they are more sensitive to changes in grout discontinuity. Additionally their occurrence (mode count) is much greater in the investigated range of frequencies up to 2 kHz. That was observed by other scientists (Emory and Zhu 2006; Wang et al. 2016), who performed their research in damage or crack detection in beams.

2.2 Modal parameters identification

The crucial point in assessment of rock bolt grout discontinuity is the diagnosis of its mechanical parameters. A structure under test is fully described by a structural model which consists of three matrices: mass distribution, stiffness and damping. A modal model of such a mechanical system, which is the counterpart to a structural model, basically consists of two matrices (Ewins 2000; Maia and Silva 1997; Remington 1997; Uhl 1997):

-

(1)

Fundamental matrix with natural frequencies and damping factors of the modes (eigenvectors) and

-

(2)

Modal matrix which consists of eigenvectors.

To construct the modal model we may start with identification of a single modal eigenvector, and a more sophisticated model (not necessarily complete) would be a set of modal eigenvectors, namely their coordinates, together with their natural frequencies and damping factors. From an individual characteristic of frequency response function Hjk(ω), where j, k stand for excitation and response points, evaluation of a natural frequency, a damping factor and a residue for an r-mode is possible.

In order to calculate coordinates of modal vectors ϕjr, which constitute the modal matrix Φ it is necessary to conduct a series of measurements of frequency response functions in different points of a tested mechanical system. The measurement of a frequency response function at excitation point is very important. The coordinates of an r-mode may be calculated knowing a residue rAkk at this point using Eq. (2):

The rest of modal vector coordinates may be calculated using Eq. (3):

where, \(\varphi_{kr} {\kern 1pt} ,\varphi_{jr}\) refer to vector coordinates after the process of normalization.

A complete presentation of vibration motion of the tested structure with n degree of freedom requires measurements of frequency response function at n different points of the structure, including a measurement at the excitation point (Maia and Silva 1997; Remington 1997; Randall 1982; Dossing 1988). That is equivalent to the measurement of frequency response functions for a column or vector of a matrix H.

As mentioned above, different lengths and positions of grouting discontinuity alter its modal parameters (Labib et al 2015) of which a resonant frequency is seen as the most valued (Salawu 1997; Sha et al. 2019). The example FRF functions (waterfall curves for different points of excitation at outer part of a rock bolt) for proper and improper grouting are presented in Fig. 3. For proper grouting, depending on the length of the outer part of a rock bolt there should be one or two natural frequencies (the first at a range approximately 200–600 Hz and the second at a range approximately 1800–2500 Hz). In certain cases the second may not be observed (above the measurement range which is 2500 Hz).

Since the natural (resonant) frequency was the main modal parameter taken into account to differentiate foregoing cases of grouting discontinuity, it was not necessary to perform measurements on the whole length of a rock bolt. The frequency response measurements were performed at 4–7 points positioned on its outer part.

In order to increase the number of measurement points and perform measurements of additional matrix elements, additional column or row of the matrix, the rock bolt was hit in the additional perpendicular direction to an axis of symmetry. It enabled calculating natural frequencies with the use of a larger number of equations and averaging obtained results in the least square sense. Additionally, it was possible to avoid a casual excitation at a nod point of a mode shape (Dossing 1988).

For realization of the method a response transducer was attached at a visible part of the rock bolt using steel ring and stud (Randall 1982) and a force transducer was localized at an impact hammer head. As pointed out above the direction of excitation was perpendicular to the symmetry axis of the rock bolt as well as was the main axis of the response transducer. After excitation of the rock bolt to transverse vibration, the signals from both the force transducer and the accelerometer (response transducer) were recorded and frequency response function (FRF) was calculated. The subsequent frequency response functions for consecutive measurement points were stored in universal file format in the computer memory. In the next step data were exported to a workstation where modal parameter extraction methods were realized. The diagnose was completed after the analytical phase had been performed in laboratory conditions. Its usage is restricted to steel rock bolts up to 2.5 m long, not only in mining but also in building engineering.

2.3 Numerical model validation

In order to localize the length and position of potential discontinuities a reference model is needed (Sinha 2002). With this aim the theoretical modal analysis was introduced (Maia and Silva 1997; Remington 1997; Uhl 1997; Randall 1982) and Finite Element (FE) models were built, encompassing different geometry (different boundary conditions) and material parameters (different rock and grout parameters). That approach of constructing a theoretical model, equivalent to an investigated real object is widely used (Ewins 2000). It is especially useful when there is a need to predict results for different modifications, here different border conditions. The theoretical models must be reconciled and it was performed in an experimental coal mine where different cases with known discontinuities were investigated and compared with theoretical ones. After the process of reconciliation, which comprised both mechanical and geometry parameters, the validated FE model could be used as a reference base for unknown experimental cases. An example of the finite element model for an analyzed case study is presented in Fig. 4. As a result of the theoretical modal analysis frequency response functions and natural frequencies were calculated (for a vast number of discontinuity cases). Then sets of natural frequencies characteristic of different types of grouting discontinuities were collected and a data base was set up. Table 1 presents the sample of data sheets for the carried-out calculations and obtained convergence charts of the analyzed cases. Therefore in the process of quality assessment of grouted rock bolts the identified natural frequencies for real objects were compared with the results of the theoretical modal calculations (set up data base). To conclude, the main diagnostic procedure is to identify the natural frequencies of assessed rock bolt and compare them with the data base of different cases with different length of discontinuity (matching of theoretically calculated and experimentally identified natural frequencies with the least error). Then we obtain the information about the geometry which is specified in that corresponding theoretical model. To enable fast and effective comparison of theoretical (FE) and experimental model regression methods were utilized (Staniek 2021). Cluster analysis seemed adequate for that purpose (Tryon 1939). The case with the least error (difference between theoretical and experimental set of natural frequencies) is what we were seeking for.

2.4 Validation of the portable measurement system fulfilling ATEX requirements

To collect data necessary for the experimental modal analysis of investigated rock bolts a measurement unit (prototype) was constructed and relevant diagnosis tests were performed in working coal and copper mines. However, as demanded for measurements in explosive atmospheres, a measurement apparatus has to fulfill ATEX directives (two EU directives describing the minimum safety requirements of the workplace and equipment used in explosive atmosphere). With that aim a new construction was designed and developed. The block diagram is shown in Fig. 5. Then a validation of the new measurement unit with the prototype version (assembled with National Instruments components) was realized. The comparison was performed in laboratory conditions and in an experimental coal mine. In laboratory a freely supported rock bolt was diagnosed. The measured frequency response functions (FRF) are shown in Fig. 6 and the measurement stand up presented in Fig. 7. The obtained results were quite consistent, it means that identified natural frequencies were reflected in the theoretical model and difference for those two measuring units was quite small; only for a higher frequency range the difference was greater, though still quite satisfactory. The test results are presented in Table 2.

The validation was also performed in the experimental coal mine on the rock bolts grouted in a controlled way utilizing the experimental stand used in previous investigations (Staniek 2011, 2021) and several rock bolts were diagnosed. The measurements were performed with previously developed working prototype and with the new measurement unit. The example results are presented below, in Table 3, where the identified natural frequencies are compared with those evaluated theoretically (FE model). It is worth noticing that also repeatability of the results (compared to the diagnosis made in the earlier stage of the research using the prototype measurement setup) was quite satisfactory. In Fig. 8 the scatter plot of the differences between FE model and data evaluated experimentally is shown (here only for the inner, hidden part of the rock bolt). The values of the lengths of discontinuity are 19 cm and 90 cm and they were also consistent for both measurement units.

Scatter plot of the differences between FE model and data evaluated experimentally (here for hidden, inner part only). The value of the length of discontinuity is specified for the first minimum differences of models (experimental and theoretical). a For measurements with the working prototype, the lower one b For measurements with the final version of the measurement unit. The discontinuity lengths are: 90 cm (inner part) and 19 cm (outer part, scatter plot not shown here)

3 Results and discussion

3.1 Measurements performed in a working coal mine

The research was continued in a working coal mine where a rock bolt support system is used to reinforce long underground openings. Mainly rock bolts of the length of 2.5 m were installed and a typical torsion force applied was 250 N m, so such a value was used in the finite element models (FE). It is not a constraint and other torsion forces may be used depending on real conditions; a thorough discussion on that topic is accessible in technical literature (Hyett et al. 2012; Cała et al. 2001). The measurements were performed periodically during about two years’ and around 70 rock bolts were tested. In Fig. 9 examples of such sessions are presented.

In the first particular area several cases were diagnosed with lack of grout approximately equaled to 0.8 m from the roof strata surface. The example of the theoretical model (rock strata elements are hidden) referring to such a case is shown in Fig. 10.

As mentioned in Sect. 2.3., the main diagnostic procedure is to identify the natural frequencies of assessed rock bolt and compare them with the data base of different cases with different length of discontinuity (comparison of experimentally identified natural frequencies with data base of sets of theoretically calculated ones with the least error). Then we obtain the information about the geometry which is specified in that best fitted, corresponding theoretical model. The identified natural frequencies of that rock bolts are presented in Table 4. For the case named 9A, the discontinuity was approximately 0.85 m. For the cases named 11A and 12A, the discontinuity was approximately 0.80 m. The characteristics of the transfer function for one of these analyzed cases and the scatter plot of the differences between FE model and data evaluated experimentally are presented in Fig. 11.

The results of estimation of the grout length: the characteristics of the transfer function for the analyzed case, the vertical axis of the chart—inertance, in (m/s2)/N, the horizontal axis—frequency, in Hz and the scatter plot of the differences between FE model and data evaluated experimentally (min value for 0.80 m)

During a consecutive session also cases with improper grouting were diagnosed, the example is described below. The identified natural frequencies of the investigated rock bolt are presented in Table 5. The results of estimation of the grout length: the characteristics of the transfer function for the analyzed case, the estimated grout length (the length of the rock bolt is equal to 2.5 m) and the scatter plot of the differences between FE model and data evaluated experimentally (min value for 0.85 m, outside the random scatter) are shown in Fig. 12.

The results of estimation of the grout length: the characteristics of the transfer function for the analyzed case (waterfall chart for points of excitation), the vertical axis of the chart—inertance, in (m/s2)/N, the horizontal axis—frequency, in Hz and the scatter plot of the differences between FE model and data evaluated experimentally. The geometry of lack of grout is also presented

There were also sessions where other types of discontinuity were found, the example is described below. The identified natural frequencies of the investigated rock bolt are presented in Table 6. The results of estimation of the grout length: the characteristics of the transfer function for the analyzed case, the estimated grout length (the length of the rock bolt is equal to 2.5 m) and the scatter plot of the differences between FE model and data evaluated experimentally (min value for 0.70 m, outside the random scatter) are shown in Fig. 13.

The results of estimation of the grout length: the characteristics of the transfer function for the analyzed case, the vertical axis of the chart—inertance, in (m/s2)/N, the horizontal axis—frequency, in Hz and the scatter plot of the differences between FE model and data evaluated experimentally. The geometry of lack of grout is also presented

3.2 Explanation of the possible reasons of improper grouting

Possible reasons of improper grouting mainly fall into two areas. On the one hand they may be of geotechnical nature such as rock divergence, escape of grout into crevices or rock strata movement. On the other they may be connected with rock bolting technology. The process of installation of rock bolts into rock strata consists mainly of four technological phases: placement of grout cartridges into a drilled hole using a rock bolt (a rock bolt is inserted up to its half length), turning phase with continued insertion of a rock bolt up to the end of the hole (depending on the environmental conditions a time period is about 10 s), spinning phase (about 4–5 s) and hold phase (about 15 s). Much effort should be taken to control these phases especially the turning and spinning ones (Staniek 2021). Otherwise grouting connection may not occur. To rapid insertion of a rock bolt may lead to leakage of grout from the hole and lack of grout in the back part (close to the end of the bore hole). Too long spinning phase may damage contact between a rock bolt and grout also in the back part (close to the end of the bore hole). It is because hardening time in that part is shorter than that in the outer part (specific preparation of grout cartridges). Too slow insertion may result in not full mixing of grout, especially at the end of a rock bolt (one of the consequences might be a rock bolt sticking out more than it is supposed to). Another reason might be a larger diameter of the hole than projected, mainly in the outer part of a hole (quite often when rock strata are hard).Then the amount of grout inserted is not enough for proper connection of a rock bolt to rock strata and it may lead to lack of grout in the outer part of the hole.

During our research in the opening where the rock bolt support system had been installed, bore holes were quite often inspected using cameras. No distinct crevices were observed and larger diameters for particular bore holes were diagnosed. Therefore the conditions described above could have caused the identified improper grouting.

4 Conclusions

In comparison to a frame support (steel arches) the rock bolt support system is less time and material consuming as well as technically more feasible. In strong rocks this system is dominant. In coal mines where rock strata are weaker, the usage of rock bolt support systems is lower. That has been observed in Polish mining industry. In recent years however, marked changes have been noticed in this area. At the same time there is no quite satisfactory non-destructive method for testing rock bolt installation integrity. It was the reason for undertaking the research on the method for identification of grouting discontinuity for rock bolts. The invented method is based on an impact excitation and uses modal analysis procedures and reconciliation of experimental and theoretical modal models.

In order to fulfill ATEX requirements, a new version of the measurement unit was designed and constructed basing on the prototype version.

Research results and calculations of finite element models of the system under test (rock bolt—resin—rock mass) indicate that the developed method and analytical application actually classifies sets of the measured natural frequencies and enables to identify cases of discontinuity (regions of lack of bonding).

The diagnosis is complete after the analytical phase performed in laboratory conditions. Its usage is restricted to steel rock bolts up to 2.5 m long (longer rock bolts were not investigated). It can be used both in mining as well as building engineering.

Using the method we may realize grouting discontinuity assessment at any time after its installation. A non-destructive character of the method is also of relevance. Moreover it is not necessary to install any additional equipment into a roof section.

References

Bačić M, Gavin K, Kovačević S (2019) Trends in non-destructive testing of rock bolts. J Croat Assoc Civil Eng GRAĐEVINAR 71(10):823–831. https://doi.org/10.14256/JCE.2727.20

Beard MD, Lowe MJS (2003) Non-destructive testing of rock bolts using ultrasonic waves. Int J Rock Mech Min Sci 40:527–536

Bergman SGA, Krauland N, Martna J, Paganus T (1983) Non-destructive field test of cement-grouted bolts with the boltometer, 5th ISRM Congress. Melbourne, Australia

Cała M, Flisiak J, Tajduś A (2001) The mechanism of interaction between rockbolt support system and rock strata of inconsistent layers positioning. Polish Academy of Science, Cracow

Dossing O (1988) Structural testing, part II: modal analysis and simulation. Bruel & Kjaer, Denmark

Emory BH, Zhu WD (2006) Experimental modal analysis of rectangular and circular beams. J STEM Educ 7(3):4

Ewins DJ (2000) Modal testing: theory, practice and application. Research Studies Press Ltd., England

Gangbing S, Weijie L, Bo W, Siu Chun MH (2017) A review of rock bolt monitoring using smart sensors. Sensors 17:776. https://doi.org/10.3390/s17040776

Godfrey DE, Kuchar NR (1977) Method of testing the integrity of installed rock bolts. United States Patent US4062229A

Haneol K, Hafeezur R, Wahid A, Abdul MN, Jung-Joo K, Jonguk K, Hankyu Y (2019) Classification of factors affecting the performance of fully grouted rock bolts with empirical classification systems. Appl Sci 9:4781

Hao Y, Wu Y, Li P, Tao J, Teng Y, Hao G (2018) Non-destructive inspection on anchorage defect of hollow grouted rock bolt using wavelet transform analysis. J Image Video Process 2018(1):1–2

Hartman W, Lecinq B, Higgs J, Tongue D (2010) Non destructive integrity testing of rock reinforcement elements in Australian mines. In: Proceedings of the 2010 Coal Operators' Conference, University of Wollongong, pp 161–170. https://ro.uow.edu.au/coal/304

Hebblewhite B, Fabjanczyk M, Gray P (2003) Investigations into premature rock bolt failures in the Australian Coal Mining Industry. In: Proceedings of the 2010 Coal Operators' Conference, University of Wollongong, pp 125–131. http://ro.uow.edu.au/coal/167

Hyett A, Mitri H, Spearing A (2012) Validation of two new technologies for monitoring the in situ performance of rock bolts. In: Proceedings of the 7th international symposium on rockbolting and rock mechanics in mining. AIMS, Aachen, pp 177–190

Kidybiński A, Nierobisz A, Masny W (2005) Maintenance of an opening affected by tremor enforced within nether roof strata. In: Proceedings of the rockbursts 2005 conference. Central Mining Institute, Poland, pp 41–52

Knape P (1988) Boltometer testing of reference bolt in the final repository for reactor waste (SFR), Forsmark. INIS:SV-UB–1988-15, Sweden

Labib A, Kennedy D, Featherston CA (2015) Crack localization in frames using natural frequency degradations. Comput Struct 157:51–59

Li CC (2017) Principles of rock bolting design. J Rock Mech Geotech Eng 9(3):396–414. https://doi.org/10.1016/j.jrmge.2017.04.002

Li Charlie C (2010) Principles of rock bolting in high stress rock masses, mining & environment, vol 2/1. Central Mining Institute, Poland, pp 133–143

Maia NMM, Silva JMM (1997) Theoretical and experimental modal analysis. Research Studies Press Ltd., England

Patil DP, Maiti SK (2005) Experimental verification of a method of detection of multiple cracks in beams based on frequency measurements. J Sound Vib 281(1–2):439–451

Randall RB (1982) Mechanical vibration and shock measurements. Bruel & Kjaer handbook, Naerum, pp 122–129

Remington PJ (1997) Experimental and theoretical studies of vibrating systems, encyclopedia of acoustics, vol 2. John Wiley & Sons, New York, pp 715–734

Sadettin O (2007) Analysis of free and forced vibration of a cracked cantilever beam. NDT&E Int 40(6):443–450

Salawu OS (1997) Detection of structural damage through changes in frequency: a review. Eng Struct 19(9):718–723

Sha G, Radzieński M, Cao M, Ostachowicz W (2019) A novel method for single and multiple damage detection in beams using relative natural frequency changes. Mech Syst Signal Process 132(1):335–352. https://doi.org/10.1016/j.ymssp.2019.06.027

Sinha JK, Friswell MI (2002) Simulation of the dynamic response of a cracked beam. Comput Struct 80(18–19):1473–1476

Staniek A (2011) Identification of discontinuities in resin layer of grouted rock bolts. Exp Tech Soc Exp Mech 36(2):12–23

Staniek A (2021) Quality assessment of installed rock bolts. In: Hammond A, Donnelly B, Ashwath N (eds) Mining Technology, ch. 4. IntechOpen, pp 55–79. https://doi.org/10.5772/intechopen.95642

Starkey A, Ivanovic A, Neilson RD, Rodger AA (2003) Using a lumped dynamic model of rock bolt to produce training data for neural network for diagnosis of real data. Meccanica 38:131–142 (Kluwer Academic Publishers)

Starkey A, Ivanovic A, Neilson RD, Rodger AA (2001) The integrity testing of ground anchorages using Granit. In: 20th international conference on ground control in mining. USA

Tadollini SC (2010) Current roof bolting applications, technologies and theories in US mines”, mining & environment, vol 2/1. Central Mining Institute, Poland, pp 305–314

Tryon RC (1939) Cluster analysis. Edwards Brothers, Ann Arbor, MI

Uhl T (1997) Computer aided identification of mechanical models. WNT, Poland

Ulusay R, Hudson JA (2007) The complete ISRM suggested methods for rock characterization. Testing and Monitoring. Ankara, Turkey, pp 1974–2006

Wang X, Hopkins C (2016) Bending, longitudinal and torsional wave transmission on Euler-Bernoulli and Timoshenko beams with high propagation losses. J Acoust Soc Am 140:2312. https://doi.org/10.1121/1.4963900

Acknowledgements

The realized research was financed by Polish Ministry of Science and High Education (11132079-171).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declare that they have no conflict of interest.

Ethical approval

The author declare that the experiments comply with the current laws of Poland (the country in which they were performed).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Staniek, A. Technical problems and non destructive testing of rock bolt support systems in mines. Int J Coal Sci Technol 10, 6 (2023). https://doi.org/10.1007/s40789-023-00566-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-023-00566-9