Abstract

Purpose

This paper proposes a Low-Frequency Adaptation-Deep Neural Network (LFA-DNN) architecture for the classification of shaft imbalance in rotatory machinery. Additionally, a Low-Frequency Adaptation-Convolution Autoencoder (LFA-CA) is proposed to address the issue of industrial noise in the signals. The paper also proposes a deep neural network-based domain adaptation approach to tackle the problem of domain shift in the feature spaces of different datasets due to fluctuating operating conditions.

Methods

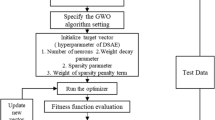

The LFA-DNN architecture is designed to extract low-frequency features from vibrational data and diagnose the presence of imbalance. The LFA-CA is specifically designed to extract signal features and reconstruct them. Domain adaptation is proposed to adapt the feature spaces of classes of one dataset to another dataset with different operating conditions. The proposed methodology is evaluated on a dataset collected experimentally with varying amounts of mass unbalance.

Results

The proposed LFA-DNN and LFA-CA architectures are effective in classifying shaft imbalance faults and denoising the signals, respectively. The proposed domain adaptation approach successfully reduces the Maximum Mean Discrepancy (MMD) between feature space distributions, thereby improving the accuracy of the model in real-world industrial settings.

Conclusions

The proposed methodology is effective in detecting and diagnosing shaft imbalance faults in industrial rotating machinery, despite the challenges of fluctuating operating conditions and industrial noise in the signals. The domain adaptation approach is effective in reducing the domain shift problem and improving the accuracy of the model. This paper provides a comprehensive approach to tackle the problem of shaft imbalance faults, which can enhance the overall product quality and the safety of workers in industrial settings.

Similar content being viewed by others

Data availability

Not applicable.

References

Oztemel E, Gursev S (2020) Literature review of industry 4.0 and related technologies. J Intell Manuf 31(1):127–182. https://doi.org/10.1007/s10845-018-1433-8

Lee J, Azamfar M, Singh J, Siahpour S (2020) Integration of digital twin and deep learning in cyber-physical systems: towards smart manufacturing. IET Collaborative Intelligent Manufacturing 2(1):34–36

Stock T, Seliger G (2016) Opportunities of sustainable manufacturing in industry 4.0. Procedia CIRP 40(Icc):536–541. https://doi.org/10.1016/j.procir.2016.01.129

Qin J, Liu Y, Grosvenor R (2016) A categorical framework of manufacturing for industry 4.0 and beyond. Procedia CIRP 52:173–178. https://doi.org/10.1016/j.procir.2016.08.005

Lee J, Davari H, Singh J, Pandhare V (2018) Industrial Artificial Intelligence for industry 4.0-based manufacturing systems. Manufacturing letters 18:20–23

Antao L, Reis J, Goncalves G (2018) Continuous maintenance system for optimal scheduling based on real-time machine monitoring. In: IEEE international conference on emerging technologies and factory automation, ETFA, vol 2018-September, pp 410–417. https://doi.org/10.1109/ETFA.2018.8502612

Azamfar M, Jia X, Pandhare V, Singh J, Davari H, Lee J (2019) Detection and diagnosis of bottle capping failures based on motor current signature analysis. Procedia Manufacturing 34:840–846

De Leon RT (2012) Vibration measurement for rotatory machines: importance of maintenance practices

Zhang C, Mousavi AA, Masri SF, Gholipour G, Yan K, Li X (2022) Vibration feature extraction using signal processing techniques for structural health monitoring: a review. Mech Syst Signal Process 177(May):109175. https://doi.org/10.1016/j.ymssp.2022.109175

Yamamoto GK, da Costa C, da Silva Sousa JS (2016) A smart experimental setup for vibration measurement and imbalance fault detection in rotating machinery. Case Stud Mech Syst Signal Process 4:8–18. https://doi.org/10.1016/j.csmssp.2016.07.001

Shahzad K, Onils M (2018) Condition monitoring in industry 4.0-design challenges and possibilities: a case study. In: 2018 Workshop on metrology for industry 4.0 and IoT, MetroInd 4.0 and IoT 2018—proceedings, pp 101–106, https://doi.org/10.1109/METROI4.2018.8428306

Morales-Perez C, Rangel-Magdaleno J, Peregrina-Barreto H, Ramirez-Cortes J (2020) Bearing fault detection on IM using MCSA and sparse representation. In: I2MTC 2020—international instrumentation and measurement technology conference, proceedings, pp 1–6. https://doi.org/10.1109/I2MTC43012.2020.9129496

Behera DP, Behera R, Naikan VNA (2014) Virtual fault simulation for diagnosis of shaft misalignment of rotating machine. In: Proceedings of the 2014 international conference on advances in computing, communications and informatics, ICACCI 2014, pp 2476–2480. https://doi.org/10.1109/ICACCI.2014.6968225

Morales-Perez C, Rangel-Magdaleno J, Peregrina-Barreto H, Ramirez-Cortes J, Vazquez-Pacheco E (2019) Bearing fault detection technique by using thermal images: a case of study. In: I2MTC 2019—2019 IEEE international instrumentation and measurement technology conference, proceedings, vol 2019-May, pp 1–6. https://doi.org/10.1109/I2MTC.2019.8826953

Tandon N, Yadava GS, Ramakrishna KM (2007) A comparison of some condition monitoring techniques for the detection of defect in induction motor ball bearings. Mech Syst Signal Process 21(1):244–256. https://doi.org/10.1016/j.ymssp.2005.08.005

Al-Badour F, Sunar M, Cheded L (2011) Vibration analysis of rotating machinery using time-frequency analysis and wavelet techniques. Mech Syst Signal Process 25(6):2083–2101. https://doi.org/10.1016/j.ymssp.2011.01.017

Amezquita-Sanchez JP, Adeli H (2016) Signal processing techniques for vibration-based health monitoring of smart structures. Arch Comput Methods Eng 23(1):1–15. https://doi.org/10.1007/s11831-014-9135-7

Yadav A, Rajagopalan S, Purohit A, Singh J (2022) Variable Dropout One-Dimensional CNN for Vibration-Based Shaft Unbalance Detection in Industrial Machinery. Journal of Vibration Engineering & Technologies 1–18

Liu Y, Wang L, Gu K, Li M (2022) Artificial neural network (ANN)—Bayesian probability framework (BPF) based method of dynamic force reconstruction under multi-source uncertainties. Knowl Based Syst 237:107796. https://doi.org/10.1016/J.KNOSYS.2021.107796

Meng Q, Lai X, Yan Z, Su CY, Wu M (2021) Motion planning and adaptive neural tracking control of an uncertain two-link rigid-flexible manipulator with vibration amplitude constraint. IEEE Trans Neural Netw Lear Syst 1:1–15. https://doi.org/10.1109/TNNLS.2021.3054611

Jablon LS, Avila SL, Borba B, Mourão GL, Freitas FL, Penz CA (2021) Diagnosis of rotating machine unbalance using machine learning algorithms on vibration orbital features. JVC J Vib Control 27(3–4):468–476. https://doi.org/10.1177/1077546320929830

Saimurugan M, Ramachandran KI, Sugumaran V, Sakthivel NR (2011) Multi component fault diagnosis of rotational mechanical system based on decision tree and support vector machine. Expert Syst Appl 38(4):3819–3826. https://doi.org/10.1016/J.ESWA.2010.09.042

Martins DHCDSS et al (2019) Application of machine learning to evaluate unbalance severity in rotating machines. Mech Mach Sci 61:144–160. https://doi.org/10.1007/978-3-319-99268-6_11

Hübner GR, Pinheiro H, de Souza CE, Franchi CM, da Rosa LD, Dias JP (2021) Detection of mass imbalance in the rotor of wind turbines using support vector machine. Renew Energy 170:49–59. https://doi.org/10.1016/J.RENENE.2021.01.080

Kornaev N, Kornaeva E, Savin L (2020) Application of artificial neural networks to fault diagnostics of rotor-bearing systems. IOP Conf Ser Mater Sci Eng 862(3):032112. https://doi.org/10.1088/1757-899X/862/3/032112

Azamfar M, Singh J, Bravo-Imaz I, Lee J (2020) Multisensor data fusion for gearbox fault diagnosis using 2-D convolutional neural network and motor current signature analysis. Mechanical Systems and Signal Processing 144:106861

Chen J et al (2019) An imbalance fault detection algorithm for variable-speed wind turbines: a deep learning approach. Energies 12(14):2764. https://doi.org/10.3390/en12142764

Tajik M, Movasagh S, Shoorehdeli MA, Yousefi I (2015) Gas turbine shaft unbalance fault detection by using vibration data and neural networks. In: International conference on robotics and mechatronics, ICROM 2015, pp 308–313. https://doi.org/10.1109/ICRoM.2015.7367802

Xue Y, Dou D, Yang J (2020) Multi-fault diagnosis of rotating machinery based on deep convolution neural network and support vector machine. Meas J Int Meas Confed 156:107571. https://doi.org/10.1016/j.measurement.2020.107571

He Q, Wang J, Liu Y, Dai D, Kong F (2012) Multiscale noise tuning of stochastic resonance for enhanced fault diagnosis in rotating machines. Mech Syst Signal Process 28:443–457. https://doi.org/10.1016/J.YMSSP.2011.11.021

Hu C, Wang Y (2019) Multidimensional denoising of rotating machine based on tensor factorization. Mech Syst Signal Process 122:273–289. https://doi.org/10.1016/J.YMSSP.2018.12.012

He W, Zi Y, Chen B, Wang S, He Z (2013) Tunable Q-factor wavelet transform denoising with neighboring coefficients and its application to rotating machinery fault diagnosis. Sci China Technol Sci 56(8):1956–1965. https://doi.org/10.1007/s11431-013-5271-9

Guo X, Shen C, Chen L (2017) Deep fault recognizer: an integrated model to denoise and extract features for fault diagnosis in rotating machinery. Appl Sci (Switzerland) 7(1):41. https://doi.org/10.3390/app7010041

Yu S, Ma J, Wang W (2019) Deep learning for denoising. Geophysics 84(6):V333–V350. https://doi.org/10.1190/geo2018-0668.1

Shao H, Jiang H, Zhao H, Wang F (2017) A novel deep autoencoder feature learning method for rotating machinery fault diagnosis. Mech Syst Signal Process 95:187–204. https://doi.org/10.1016/J.YMSSP.2017.03.034

Shao H, Jiang H, Zhang H, Liang T (2018) Electric locomotive bearing fault diagnosis using a novel convolutional deep belief network. IEEE Trans Ind Electron 65(3):2727–2736. https://doi.org/10.1109/TIE.2017.2745473

Weiss K, Khoshgoftaar TM, Wang DD (2016) A survey of transfer learning. J Big Data. https://doi.org/10.1186/s40537-016-0043-6

Science PS, Fusion C (2021) ce pte d M us

Pan SJ, Tsang IW, Kwok JT, Yang Q (2011) Domain adaptation via transfer component analysis. IEEE Trans Neural Netw 22(2):199–210. https://doi.org/10.1109/TNN.2010.2091281

Sun S, Shi H, Wu Y (2015) A survey of multi-source domain adaptation. Inf Fusion 24:84–92. https://doi.org/10.1016/j.inffus.2014.12.003

Ma S, Chu F (2019) Ensemble deep learning-based fault diagnosis of rotor bearing systems. Comput Ind 105:143–152. https://doi.org/10.1016/j.compind.2018.12.012

Shao H, Jiang H, Lin Y, Li X (2018) A novel method for intelligent fault diagnosis of rolling bearings using ensemble deep auto-encoders. Mech Syst Signal Process 102:278–297. https://doi.org/10.1016/j.ymssp.2017.09.026

Neupane D, Seok J (2020) Bearing fault detection and diagnosis using case western reserve university dataset with deep learning approaches: a review. IEEE Access 8:93155–93178. https://doi.org/10.1109/ACCESS.2020.2990528

Jian Y, Qing X, He L, Zhao Y, Qi X, Du M (2019) Fault diagnosis of motor bearing based on deep learning. Adv Mech Eng 11(9):1–9. https://doi.org/10.1177/1687814019875620

Shao SY, Sun WJ, Yan RQ, Wang P, Gao RX (2017) A deep learning approach for fault diagnosis of induction motors in manufacturing. Chin J Mech Eng (English Ed.) 30(6):1347–1356. https://doi.org/10.1007/s10033-017-0189-y

Gecgel O, Ekwaro-Osire S, Dias JP, Serwadda A, Alemayehu FM, Nispel A (2019) Gearbox fault diagnostics using deep learning with simulated data. In: 2019 IEEE international conference on prognostics and health management, ICPHM 2019. https://doi.org/10.1109/ICPHM.2019.8819423

Liu L, Chen L, Wang Z, Liu D (2021) Early fault detection of planetary gearbox based on acoustic emission and improved variational mode decomposition. IEEE Sens J 21(2):1735–1745. https://doi.org/10.1109/JSEN.2020.3015884

Lei Y, He Z, Zi Y (2009) Application of the EEMD method to rotor fault diagnosis of rotating machinery. Mech Syst Signal Process 23(4):1327–1338. https://doi.org/10.1016/j.ymssp.2008.11.005

Lee J, Park B, Lee C (2020) Fault diagnosis based on the quantification of the fault features in a rotary machine. Appl Soft Comput 97:106726. https://doi.org/10.1016/j.asoc.2020.106726

Yu HT, Kim HJ, Park SH, Kim MH, Jeon IS, Choi BK (2022) Classification of rotary machine fault considering signal differences. J Mech Sci Technol 36(2):517–525. https://doi.org/10.1007/s12206-022-0101-2

Saha DK, Hoque ME, Badihi H (2022) Development of intelligent fault diagnosis technique of rotary machine element bearing: a machine learning approach. Sensors 22(3):1073. https://doi.org/10.3390/s22031073

Chen Z, Gryllias K, Li W (2020) Intelligent fault diagnosis for rotary machinery using transferable convolutional neural network. IEEE Trans Ind Inf 16(1):339–349. https://doi.org/10.1109/TII.2019.2917233

Zhang C, Xu L, Li X, Wang H (2019) A method of fault diagnosis for rotary equipment based on deep learning. In: Proceedings—2018 prognostics and system health management conference, PHM-Chongqing 2018, pp 958–962. https://doi.org/10.1109/PHM-Chongqing.2018.00171

Grasso M, Chatterton S, Pennacchi P, Colosimo BM (2016) A data-driven method to enhance vibration signal decomposition for rolling bearing fault analysis. Mech Syst Signal Process 81:126–147. https://doi.org/10.1016/j.ymssp.2016.02.067

Natu M (2012) Bearing fault analysis using frequency and wavelet techniques. Int J Innov Manag Technol 15(6):72–74. https://doi.org/10.7763/IJIMT.2013.V4.365

Malik H, Mishra S (2016) Proximal support vector machine (PSVM) based imbalance fault diagnosis of wind turbine using generator current signals. Energy Procedia 90(December 2014):593–603. https://doi.org/10.1016/j.egypro.2016.11.228

. Kerezsi B, Howard I (1995) Vibration fault detection of large turbogenerators using neural networks. In: IEEE international conference on neural networks—conference proceedings, vol 1, pp 121–126. https://doi.org/10.1109/icnn.1995.488078

Grais EM, Plumbley MD (2017) Single channel audio source separation using convolutional denoising autoencoders. pp 1265–1269

Chiang HT, Hsieh YY, Fu SW, Hung KH, Tsao Y, Chien SY (2019) Noise reduction in ECG signals using fully convolutional denoising autoencoders. IEEE Access 7:60806–60813. https://doi.org/10.1109/ACCESS.2019.2912036

Gao S, Zhang Y, Jia K, Lu J, Zhang Y (2015) Single sample face recognition via learning deep supervised autoencoders. IEEE Trans Inf Forensics Secur 10(10):2108–2118. https://doi.org/10.1109/TIFS.2015.2446438

Guo Y, Jiao L, Wang S, Wang S, Liu F (2018) Fuzzy sparse autoencoder framework for single image per person face recognition. IEEE Trans Cybern 48(8):2402–2415. https://doi.org/10.1109/TCYB.2017.2739338

Sun W, Shao S, Zhao R, Yan R, Zhang X, Chen X (2016) A sparse auto-encoder-based deep neural network approach for induction motor faults classification. Meas J Int Meas Confed 89:171–178. https://doi.org/10.1016/j.measurement.2016.04.007

Zhou P, Han J, Cheng G, Zhang B (2019) Learning compact and discriminative stacked autoencoder for hyperspectral image classification. IEEE Trans Geosci Remote Sens 57(7):4823–4833. https://doi.org/10.1109/TGRS.2019.2893180

Xing C, Ma L, Yang X (2016) Stacked denoise autoencoder based feature extraction and classification for hyperspectral images. J Sens. https://doi.org/10.1155/2016/3632943

Yu J, Hong C, Rui Y, Tao D (2018) Multitask autoencoder model for recovering human poses. IEEE Trans Ind Electron 65(6):5060–5068. https://doi.org/10.1109/TIE.2017.2739691

Ribeiro M, Lazzaretti AE, Lopes HS (2018) A study of deep convolutional auto-encoders for anomaly detection in videos. Pattern Recogn Lett 105:13–22. https://doi.org/10.1016/j.patrec.2017.07.016

Jogin M, Mohana, Madhulika MS, Divya GD, Meghana RK, Apoorva S (2018) Feature extraction using convolution neural networks (CNN) and deep learning. In: 2018 3rd IEEE international conference on recent trends in electronics, information and communication technology, RTEICT 2018—proceedings, no. November, pp 2319–2323. https://doi.org/10.1109/RTEICT42901.2018.9012507

Doll P, Girshick R, Ai F. Mask R-CNN ar

Ali Chishti SO, Riaz S, Bilal Zaib M, Nauman M (2018) Self-driving cars using CNN and Q-learning. In: Proceedings of the 21st international multi topic conference, INMIC 2018. https://doi.org/10.1109/INMIC.2018.8595684

Bojarski M et al (2016) End to end learning for self-driving cars. pp 1–9

Parkhi OM, Vedaldi A, Zisserman A (2015) Deep face recognition. no. section 3, pp 41.1–41.12. https://doi.org/10.5244/c.29.41

Yang YX, Wen C, Xie K, Wen FQ, Sheng GQ, Tang XG (2018) Face recognition using the SR-CNN model. Sensors (Switzerland) 18(12):4237. https://doi.org/10.3390/s18124237

Tomashenko N, Khokhlov Y (2014) Speaker adaptation of context dependent deep neural networks based on MAP-adaptation and GMM-derived feature processing. In: Proceedings of the Annual Conference of the International Speech Communication Association, INTERSPEECH, no. September, pp 2997–3001

Jia F, Lei Y, Lin J, Zhou X, Lu N (2016) Deep neural networks: a promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech Syst Signal Process 72–73:303–315. https://doi.org/10.1016/j.ymssp.2015.10.025

Ballinger CB (1977) Psychiatric morbidity and the menopause: survey of a gynaecological out patient clinic. Br J Psychiatry 131(7):83–89. https://doi.org/10.1192/bjp.131.1.83

Chen LC, Papandreou G, Kokkinos I, Murphy K, Yuille AL (2018) DeepLab: semantic image segmentation with deep convolutional nets, atrous convolution, and fully connected CRFs. IEEE Trans Pattern Anal Mach Intell 40(4):834–848. https://doi.org/10.1109/TPAMI.2017.2699184

Mekhazni D, Bhuiyan A, Ekladious G, Granger E (2020) Unsupervised domain adaptation in the dissimilarity space for person re-identification, vol. 12372. Lecture Notes in Computer Science (including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics), LNCS. pp 159–174. https://doi.org/10.1007/978-3-030-58583-9_10

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arora, J.K., Rajagopalan, S., Singh, J. et al. Low-Frequency Adaptation-Deep Neural Network-Based Domain Adaptation Approach for Shaft Imbalance Fault Diagnosis. J. Vib. Eng. Technol. 12, 375–394 (2024). https://doi.org/10.1007/s42417-022-00848-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-022-00848-7