Abstract

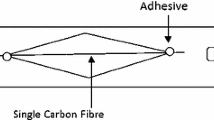

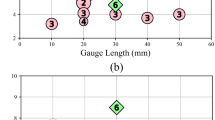

The effect of cross-sectional shape on tensile strength of pitch-based carbon fibres was investigated by extensive single-filament testing. For this study, round and trilobal pitch-based carbon fibres were produced at similar processing conditions. The application of a variety of distributions, including the simple Weibull distribution, to the strength data indicated two sources of failure, one source being the accentuation of end effects at short gauge lengths. A new mixed distribution, the end-effect distribution, was proposed to account for these effects and applied to the experimental data. The end-effect model provided an excellent description of the strength distributions of all fibres studied. The end-effect distribution is not complex and is based on sound physical assumptions. It quantifies a recognized inadequacy of the test method which has not previously been accounted for, and it allows separation of end effects from the true fibre strength distribution. The results indicate that end effects can be an important concern for gauge lengths as long as 40 mm. Use of this model revealed that, in the absence of end effects, all fibres failed due to macroscopic flaws; thus, varying the fibre geometry does not result in an unusual failure mechanism. However, the tensile strengths of the non-circular fibre were found to be less dependent on fibre size. Thus, non-circular fibres can be produced at higher mass flow rates, decreasing filament breakage and increasing process conversions.

Similar content being viewed by others

References

J. B. Jones, J. B. Barr and R. E. Smith, J. Mater. Sci. 15 (1980) 2465.

D. D. Edie, N. K. Fox, B. C. Barnett and C. C. Fain, Carbon 24 (1986) 477.

H. E. Gainey, D. D. Edie, J. M. Kennedy and C. C. Fain, “Carbon 88”, Proceedings of the Seventh International Carbon Conference, Newcastle, UK edited by B. McEnaney and T. J. Mays (IOP, Bristol, 1988) p. 494.

E. G. Stoner, PhD dissertation, Clemson University, Clemson, SC (1991).

ASTM Standard, D3379-75, Reapproved 1989 (American Society for Testing and Materials, Philadelphia, PA).

J. W. Hitchons and D. C. Phillips, Fibre Sci. Technol. 12 (1979) 217.

C. P. Beetz, Jr. ibid. 16 (1982) 45.

H. D. Wagner and S. L. Phoenix, J. Compos. Mater. 18 (1984) 312.

W. Nelson, “Applied Life Data Analysis” (Wiley, New York, 1982).

K. K. Phani, J. Mater. Sci. 6 (1987) 1176.

Idem, ibid. K. K. Phani, J. Mater. Sci. 23 (1988) 1189.

C. A. Johnson, in “Fracture Mechanics of Ceramics 5” edited by R. C. Bradt, A. G. Evans, D. P. H. Hasselman and F. F. Lange (Plenum Press, New York, 1985) pp. 365–86.

C. P. Beetz, Jr, Fibre Sci. Technol. 16 (1982) 81.

L. S. Singer, US Pat. 4005 183 (1977).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Stoner, E.G., Edie, D.D. & Durham, S.D. An end-effect model for the single-filament tensile test. JOURNAL OF MATERIALS SCIENCE 29, 6561–6574 (1994). https://doi.org/10.1007/BF00354022

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00354022