Abstract

Scale-up of stirred tank bioreactors from 0.02 m3 to 0.3 m3 commercial plant is discussed for hybridoma suspension culture. Schemes for dissolved oxygen control with sparged air in serum containing media are described as well as mechanical breakage of foam in small and large bioreactors. Porous metal spargers (180−200×10−6 m) are found to produce foams which are hard to control. Aeration with larger (> 0.001 m) multihole spargers is recommended.

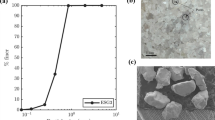

Combined cell damage due to foam formation and control, and possible damage at mechanical seals or submerged bearings, are found to have no measurable effect on cell growth relative to roller bottle production. Hybridomas are shown to withstand significant impeller tip speed (> 1 ms−1) and fluid turbulence as evidenced by impeller Reynolds numbers in excess of 105. The size of the energy dissipating terminal eddies is calculated to be > 10-fold that of the hybridoma cells. Specific fluid turnover rate is employed as the scale-up criterion.

Similar content being viewed by others

Abbreviations

- C m:

-

Clearance of impeller from bottom of tank

- D m:

-

Diameter of tank

- DO kg/m3 :

-

Dissolved oxygen

- d i m:

-

Diameter of impeller

- k L a L 1/s:

-

Overall gas-liquid volumetric mass transfer coefficient

- L m:

-

Static liquid height

- l m:

-

Length of terminal eddies

- N 1/s:

-

Rotational speed of impeller

- P W:

-

Power

- Po :

-

Power number

- Q m3/s:

-

Volume flow of impeller

- Re i :

-

Impeller Reynolds number given by Eq. (1)

- RO:

-

Reverse osmosis

- T m/s:

-

Tip speed of impeller

- V m3 :

-

Volume of bioreactor

- ɛ W/kg:

-

Specific energy dissipation rate

- μ Pa · s:

-

Viscosity of liquid

- ρ kg/m3 :

-

Density of liquid

- 1:

-

0.02 m2 bioreactor

- 2:

-

0.3 m3 bioreactor

References

Macmillan, J. D.; Velez, D.; Miller, L.; Reuveny, S.: Monoclonal antibody production in stirred reactors. In: Lydersen. B. K. (Editor) Large scale cell culture technology, pp. 21–58, Hanser Publishers, New York, 1987.

Tolbert, W. R.: Large-scale cell culture technology. Annual Reports on Fermentation Processes 6 (1983) 35–74

Arathoon, W. R.; Birch, J. R.: Large-scale cell culture in biotechnology. Science 232 (1986) 1390–1395

Birch, J. R.; Lambert, K.; Thompson, P. W.; Kenney, A. C.; Wood, L. A.: Antibody production with airlift fermentors. In: Lydersen, B. K. (Editor) Large scale cell culture technology, pp. 1–20, Hanser Publishers, New York, 1987

Rhodes, M., Birch, J.: Large-scale production of proteins from mammalian cells. Biotechnology 6 (1988) 518–523

Wilkinson, P. J.: The development of a large scale production process. In: Moody, G. W.; Baker, P. B. (Editors) Bioreactors and biotransformations, pp. 111–120, Elsevier, London, 1987

Lubiniecke, A. S. (Editor) Large-scale Mammalian cell culture technology, p. 624, Marcel Dekker, New York, 1990

Bailey, J. E.; Ollis, D. F.: Biochemical engineering fundamentals, pp. 444–451; 458–464, McGraw-Hill, New York, 1977

Chisti, Y.; Moo-Young, M.: Fermentation technology, bioprocessing, scale-up and manufacture. In: Moses, V.; Cape, R. E. (Editors) Biotechnology: The science and the business, pp. 167–209. Harwood Academic Publishers, New York, 1991.

Chisti, Y.: Assure bioreactor sterility. Chem. Eng. Progress 88 (1992) 9, 80–85

Chisti, M. Y.: Airlift bioreactors, p. 345. Elsevier, New York, 1989

Yabannavar, V. M.; Singh, V.; Connelly, N. V.: Mammalian cell retention in a spinfilter perfusion bioreactor. Biotechnol. Bioeng. 40 (1992) 925–933

Lee, E. K.; Huang, L.; Lee, Y. H.: Effect of liquid properties and flow on liquid film mass transfer coefficient in silicone membrane oxygenation. Biotechnol. Bioeng. 36 (1990) 530–533

Chisti, Y.: Build better industrial bioreactors. Chem. Eng. Progress 88 (1992) 1, 55–58

Goldblum, S.; Yong-Kook, B.; Hink, F. W.; Chalmers, J.; Protective effect of methylcellulose and other polymers on insect cells subjected to laminar shear stress. Biotechnol. Progress 6 (1990) 383–390

Chisti, Y.; Moo-Young, M.: On the calculation of shear rate and apparent viscosity in airlift and bubble column bioreactors. Biotechnol. Bioeng. 34 (1989) 1391–1392

Moo-Young, M.; Blanch, H. W.: Design of biochemical reactors: Mass transfer criteria for simple and complex systems. Adv. Biochemical Engineering 19 (1981) 1–69

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chisti, Y. Animal cell culture in stirred bioreactors: Observations on scale-up. Bioprocess Engineering 9, 191–196 (1993). https://doi.org/10.1007/BF00369402

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00369402