Abstract

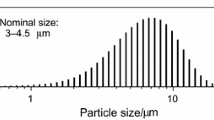

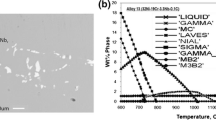

A study has been performed of the oxidation and degassing processes of aluminium-based alloy powders. Oxidation and hydration of gas-atomized metal powders take place during inflight solidification and cooling to room temperature, during collection and keeping in the powder collection box and during transport and storage before consolidation. Under the atomizing conditions, oxidation cannot be prevented. In contact with humid gases (air) the oxide layer on the powder surface takes up water vapour which is physically or chemically bound. A literature study shows that the oxide layer on atomized aluminium powder is amorphous and has a thickness of 2–10 nm depending on the atomizing conditions. The amount of water in the powder is sufficient to form a completely closed hydroxide layer on the outer surface of the powder. The thickness growth of the oxide layer is governed by cation diffusion. Degassing experiments were carried out by heating canned powders in vacuum. The partial pressures of evolved water vapour and hydrogen were registered as a function of temperature at a constant heating rate. Two different alloy powders were used: the first air atomized and containing 1% magnesium (Al-20Si-3Cu-1Mg-5Fe), and the second (Al-9Fe-2Mo-1Zr) magnesium-free powder, atomized by nitrogen. Much work has been done on degassing, but most of it is directed towards industrial applications. The quantitative theoretical description of the degassing phenomenon is still lacking. A new approach aiming at narrowing this gap is presented by employing Wagner's theory of high temperature oxidation of metals. The diffusion coefficient of aluminium cations through the amorphous aluminium oxide layer has been determined in the degassing temperature range by using the experimental data of Hayden et al. The diffusion coefficient of aluminium cations through the Al2O3 layer has also been evaluated from the degassing experiments. The values obtained directly from the degassing experiments are in reasonable agreement with those derived from the oxidation results. It has been concluded that extrapolation of the results obtained from diffusion experiments at high temperatures in aluminium oxides towards the temperature range of degassing cannot explain the formation of hydrogen during this process, even if the surface diffusion coefficient (much higher than lattice diffusion coefficient) is taken into account.

Similar content being viewed by others

References

J. L. Estrada, J. Duszczyk and B. M. Korevaar, J. Mater. Sci. 26 (1991) 1431.

S. D. Kirchoff, J. Y. Adkins, W. M. Griffith and I. A. Martorell, in “Rapidly Solidified Powder Aluminium Alloys”, ASTM STP 890, edited by M. E. Fine and E. A. Starke (American Society for Testing and Materials, Philadelphia, PA, 1986) p. 354.

T. J. Carney, P. Tsakiropoulos, J. F. Watts and J. E. Castle, Int. J. Rapid Solid. 5 (1990) 189.

B. E. Hayden, W. Wyrobisch, W. Oppermann, S. Hachicha, P. Hofmann and A. M. Bradshaw, Surface Sci. 109 (1981) 221.

N. Cabrera and N. F. Mott, Rep. Progr. Phys. 12 (1948/49) 163.

A. L. Litvintsev and L. A. Arbuzova, Poroskhovaya Metallurgiya 49 (1967) 1.

L. Ackermann, I. Guillemin, R. Lalauze and C. Pijolat, in “High Strength Powder Metallurgy Aluminium Alloys II”, edited by G. J. Hildeman and M. J. Koczak (The Metallurgical Society of AIME Warrendale, PA, 1986) p. 175

J. Zhou, J. Duszczyk and B. M. Korevaar, J. Mater. Sci. 26 (1991) 3292.

K. Shimizu, R. C. Furneaux, G. E. Thompson, G. C. Wood, A. Gotoh and K. Kobayashi, Oxid. Metals 35 (1991) 427.

J. L. Estrada and J. Duszczyk, J. Mater. Sci. 25 (1990) 886.

C. Wagner, in “Atom Movements” (American Society for Metals, Cleveland, OH, 1951) p. 153.

A. E. Paladino and W. D. Kingery, J. Chem. Phys. 37 (1962) 957.

A. F. Beck, M. A. Heine, E. J. Canle and M. J. Pryor, Corros. Sci. 7 (1967) 1.

W. W. Schmeltzer, J. Etectrochem. Soc. 103 (1956) 209.

E. A. Gulbransen and W. S. Wysong, J. Phys. Colloid Chem. 57 (1947) 10187.

R. K. Hart and J. K. Maurin, Surface Sci. 20 (1970) 285.

Y. Ikuma and W. Komatsu, Mater. Sci. Forum 29 (1988) 199.

J. Barin and O. Knacke, in “Thermochemical Properties of Inorganic Substances” (Springer Verlag, Berlin, 1973).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kowalski, L., Korevaar, B.M. & Duszczyk, J. Some new aspects of the theory of oxidation and degassing of aluminium-based alloy powders. J Mater Sci 27, 2770–2780 (1992). https://doi.org/10.1007/BF00540704

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00540704