Abstract

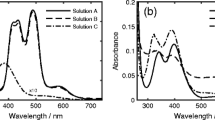

The electrocrystallization of Ni is known to be a highly inhibited process. This work gives some conclusions about the nature of the major inhibiting species. All of these species are formed in the catholyte because of the hydrogen codeposition. Depending on plating conditions, mainly pH and current density of metallic deposition, we observe a predominancy of a definite inhibitor which selectively promotes one mode of growth and leads to a deposit exhibiting definite structural properties. A careful structural investigation of Ni deposits obtained from a Watts solution, thanks to both X-ray diffractometry and electron-microscope techniques, leads us to distinguish a free mode of growth, which is characterized by [100] oriented deposits, from several inhibited modes such as 〈110〉, [210], 〈211〉 and 〈111〉. The two latter are stabilized by Ni(OH)2 while the two former are respectively due to atomic and molecular forms of adsorbed hydrogen.

Similar content being viewed by others

References

H. Fischer, ‘Elektrolytische Abscheidung und Elektrokristallisation von Metallen’, Springer, Berlin (1954).

Idem, Electrodep. Surf. Treat. 1 (1973) 239.

Idem, ibid, Electrodep. Surf. Treat.,1 (1973) 319.

R. Piontelli and G. Serravalle.Tram. Inst. Metal Finishing 34 (1957) 293.

M. Froment and A. Ostrowiecki,Métaux Corrosion Ind. 487 (1966) 83.

M. Froment, G. Maurin and J. Thevenin,Comptes Rendus Acad. Sci. Paris 264C (1967) 1520.

J. Amblard, thesis, Paris (1976).

J. Amblard, M. Froment and G. Maurin,Electrodep. Surf. Treat. 2 (1974) 205.

J. Amblard, M. Froment and N. Spyrellis,Surf. Technol. 5 (1977) 205.

G. Maurin and M. Froment,Métaux Corrosion Ind. 487 (1966) 103.

M. Froment and G. Maurin,J. Microscopie 7 (1968) 39.

G. Maurin,Oberfläche-Surface 11 (1970) 297 309.

Idem, ibid,12 (1971) 8, 24, 47, 54.

I. Epelboin, M. Froment and G. Maurin,Plating 56 (1969) 1356.

J. Amblard, M. Froment and S. Vitkova, Communication at the28th ISE Meeting Druzhba near Varna (1977) p. 427.

I. Epelboin, M. Froment and G. Maurin,ibid p. 371.

J. Amblard, Th. Costavaras, A. Hugot-Le Goff and N. Spyrellis,Oberfläche-Surface 18 (1977) 1.

R. Wiart,ibid,9 (1968) 213, 241, 273.

H. Brown,Plating 55 (1968) 1047.

I. Dubsky and P. Kozak,Metalloberfläche 24 (1970) 423.

R. J. Kendrick,Trans. Inst. Met. Finishing 40 (1963) 19.

H. Brown, Comm. atInterfinish Bâle (1972) p. 114.

M. Froment, G. Maurin and J. Thevenin,J. Microscopie 8 (1969) 521.

A. Knödler,Metalloberfläche 20 (1966) 52.

M. Froment,J. Microscopie 3 (1964) 61.

J. Amblard and M. Froment, Communication at the12th Faraday Symposium Southampton (1977) p. 136.

N. A. Pangarov,J. Electroanalyt. Chem. 9 (1965) 70.

J. Thevenin,J. Microsc. Spectr. Electron 1 (1976) 7.

A. K. N. Reddy and S. R. Ragagopalan,J. Electroanalyt. Chem. 6 (1963) 141, 153, 159.

R. K. Dorsch,ibid,21 (1969) 495.

I. Epelboin, P. Morel and H. Takenouti,J. Electrochem. Soc. 118 (1971) 1282.

A. G. Ives, J. W. Edington and G. B. Rothwell,Electrochim. Acta 15 (1970) 1797.

S. I. Berezina, L. V. Burnasheva, A. N. Gil'manov, I. Kh. Muzeev and R. M. Sageeva,Elektrokhimiya 10 (1974) 948.

M. Pourbaix, MAtlas d'équilibres électrochimiques à 25° C', Gauthier Villars, Paris (1963) p. 333.

F. Denise and H. Leidheiser Jr.,J. Electrochem. Soc. 100 (1953) 490.

D. J. Evans,Trans. Faraday Soc. 54 (1958) 1086.

B. Rivolta, L. Peraldo Bicelli and G. Razzini,J. Phys. D: Appl. Phys. 8 (1975) 2025.

M. Froment, G. Maurin and J. Thevenin,Comptes Rendus Acad. Sci. Paris 269C (1969) 1367.

J. Matulis and R. Slizys,Electrochim. Acta 9 (1964) 1177.

I. Epelboin and R. Wiart,J. Electrochem. Soc. 118 (1971) 1577.

H. Leidheiser Jr. and A. T. Gwathmey,ibid,98 (1951) 225.

K. R. Lawless,Phys. Thin Films 4 (1967) 191.

S. K. Verma and H. Wilman,J. Phys. D: Appl. Phys. 4 (1971) 1167.

J. Thevenin, thesis, Paris (1974).

B. Le Gorrec and J. Guitton,Comptes Rendus Acad. Sci. Paris 272C (1971) 1784, 2031.

J. Bressan, I. Epelboin, R. Wiart, Communication of the Department of Chemistry, Acad. Sci. Bulgaria, Special Issue in honour of Professor Kaischew (in press).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Amblard, J., Epelboin, I., Froment, M. et al. Inhibition and nickel electrocrystallization. J Appl Electrochem 9, 233–242 (1979). https://doi.org/10.1007/BF00616093

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00616093