Abstract

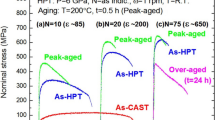

The development of intergranular oxides in dilute Ni-Al alloys containing 0.55–4.10% Al in Ni-NiO packs and in 1 atm oxygen at 800–1100°C has been examined. In the Ni-NiO packs, preferential intergranular oxide penetration as well as internal oxidation occurs in every case, except in the higher aluminum-containing alloys at 1100°C. Several different types of intergranular oxide morphology were observed, depending on alloy aluminum concentration and on temperature. The oxides in the more dilute alloys are thin and relatively continuous and are accompanied by preferential penetration of internal oxide particles in the adjacent grains. Thicker intergranular oxides are precipitated in the more concentrated alloys while, in some situations, numerous fine oxide particles are formed well ahead of the main intergranular oxide. The intergranular oxidation is facilitated by high stress development in the specimens due to increases in volume as internal and intergranular oxides are formed. These stresses create microvoids in the grain boundaries immediately ahead of the advancing internal and intergranular oxides, resulting in preferential nucleation and growth of further intergranular oxides. This is the case particularly at the lower temperatures where other stress-relief processes cannot operate. The resulting relatively continuous, incoherent intergranular oxide-metal interface allows a high flux of oxygen to the advancing intergranular oxide front. Preferential intergranular oxidation is much less extensive in the presence of a thickening external NiO scale, due to accommodation of the volume increases on internal oxide formation by vacancies injected into the alloy from the growing cationdeficient scale.

Similar content being viewed by others

References

J. S. Wolf, J. W. Weeton, and J. C. Freche, NASA Tech. Note TN-D-2813 (1965).

J. S. Wolf and E. B. Evans,Corrosion 18, 129t (1962).

S. Goto and S. Koda,J. Jpn. Inst. Metals 32, 334 (1968).

S. Goto, K. Nomaki, and S. Koda,J. Jpn. Inst. Metals 31, 600 (1967).

Y. Miyoshi and S. Kado,J. Jpn. Inst. Metals 31, 481 (1967).

F. N. Rhines and A. H. Grobe,Trans. AIME 147, 318 (1942).

F. N. Rhines,Trans. AIME 137, 246 (1940).

F. H. Stott, Y. Shida, D. P. Whittle, G. C. Wood, and B. D. Bastow,Oxid. Met. 18, 127 (1982).

D. P. Whittle, Y. Shida, G. C. Wood, F. H. Stott, and B. D. Bastow, to be published.

Y. Shida, D. P. Whittle, G. C. Wood, F. H. Stott, and B. D. Bastow, to be published.

D. McLean,Mechanical Properties of Metals (John Wiley & Sons Inc., New York, 1972).

D. P. Whittle and H. Hindam, to be published.

G. C. Wood, F. H. Stott, D. P. Whittle, Y. Shida, and B. D. Bastow, to be published.

Author information

Authors and Affiliations

Additional information

British Nuclear Fuels, Windscale Works, Seascale, Cumbria, U.K.

Rights and permissions

About this article

Cite this article

Shida, Y., Stott, F.H., Bastow, B.D. et al. Development of preferential intergranular oxides in nickel-aluminum alloys at high temperatures. Oxid Met 18, 93–113 (1982). https://doi.org/10.1007/BF00662032

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00662032