Abstract

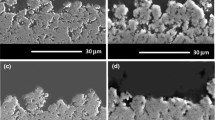

During like-on-like reciprocating sliding in air (amplitude 2.5 mm, load 1.5 kg, speed 500 double traversais per minute), the formation of oxides can have considerable influence on the friction and wear characteristics of high-temperature alloys, such as Jethete M152 and Rex 535. In particular, above a certain transition temperature, between 200 and 300°C for these alloys under these conditions, an adherent, smooth wear-protective oxide layer is developed on the load-bearing surfaces. At lower temperatures, oxide debris reduces the extent of metal-metal contact, thereby reducing the friction and wear rate, but does not eliminate it completely. The oxide debris is produced by two processes; one involves transient oxidation of the metal surfaces, removal of such oxide during each transversal, and reoxidation of the exposed metal; the other involves the formation, fracture, comminution, and oxidation of metal debris particles. At temperatures above the transition temperature, the oxide debris is compacted and comminuted between the sliding surfaces to develop the wear-protective oxide layer. This paper considers the reasons for the effectiveness of such oxides in terms of the influence of the hydrostatic pressures generated on plastic deformation of the very fine oxide particles or asperities in the surface. The resulting friction during sliding is less than during metal-metal contact because only limited asperity junction growth occurs before the asperities become sufficiently large and the hydrostatic pressures sufficiently reduced to allow fracture within the oxide-oxide junctions. The oxide-wear debris produced is recompacted into the surface, resulting in only very low wear rates. It has been shown that the number of asperity-asperity contacts during sliding of wear-protective oxide layers is relatively high, typically 5×103/mm2 of apparent contact area, while the mean surface flash temperature rise is low, typically 2°C. Consideration is given to some of the conditions that favor development of wear-protective oxide layers.

Similar content being viewed by others

References

M. P. Peterson, J. J. Florek, and R. E. Lee,ASLE Trans. 3, 101 (1960).

D. H. Buckley and R. L. Johnson,ASLE Trans. 3, 93 (1960).

D. S. Lin, F. H. Stott, and G. C. Wood,ASLE Trans. 17, 251 (1974).

F. H. Stott, D. S. Lin, and G. C. Wood,Corr. Sci. 13, 449 (1973).

T. F. J. Quinn,Wear 18, 413 (1971).

F. H. Stott and G. C. Wood,Tribology 11, 211 (1978).

D. J. Barnes, J. E. Wilson, F. H. Stott, and G. C. Wood,Wear 45, 161 (1977).

A. C. Jesper,Proc. Inst. Mech. Eng. 180Pt 3K, Paper 15 (1965).

F. H. Stott, D. S. Lin, G. C. Wood, and C. W. Stevenson,Wear 36, 147 (1976).

J. Glascott, F. H. Stott, and G. C. Wood,Wear 97, 155 (1984).

F. H. Stott, J. Glascott, and G. C. Wood,Wear 101, 311 (1985).

F. H. Stott, J. Glascott, and G. C. Wood,Wear 97, 93 (1984).

J. Glascott, G. C. Wood, and F. H. Stott,Proc. Inst. Mech. Eng. 119, 35 (1985).

F. H. Stott, J. Glascott, and G. C. Wood,J. Phys. D: Appl. Phys. 18, 541 (1985).

F. H. Stott, G. C. Wood, and J. Glascott, submitted for publication.

J. Glascott, Ph.D. Thesis, University of Manchester (1982).

P. W. Bridgeman,J. Appl. Phys. 18, 246 (1947).

D. Tabor,The Hardness of Metals (Clarendon Press, Oxford, 1951).

H. Hencky,Z. Angew. Math. Mech. 3, 241 (1923).

G. C. Wood and T. Hodgkiess,Werkst. Korr. 9, 766 (1972).

F. P. Bowden and C. A. Brookes,Proc. Roy. Soc. A295, 244 (1966).

R. F. King and D. Tabor,Proc. Roy. Soc. A223, 225 (1954).

J. P. A. Tillet,Proc. Phys. Soc. B69, 47 (1956).

F. C. Frank and B. R. Lawn,Proc. Roy. Soc. A299, 291 (1949).

R. M. Davies,Proc. Roy. Soc. A197, 416 (1949).

G. H. Hamilton and L. E. Goodman,J. Appl. Mech. 33, 371 (1966).

D. Tabor,Proc. Roy. Soc. A251, 378 (1959).

J. H. Westbrook,Rev. Hautes Tem. Refract. 3, 47 (1966).

J. F. Archard,Wear 2, 438 (1959).

M. F. Amateau and W. A. Glaeser,Wear 7, 385 (1964).

F. K. Orcutt, H. H. Krauss, and C. M. Allen,Wear 5, 345 (1962).

J. M. Palacios, A. Rincon, and I. Arijmendi,Wear 60, 393 (1980).

T. K. Gupta,J. Math. Sci. 9, 1585 (1974).

F. A. Golightly, F. H. Stott, and G. C. Wood, unpublished work.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Glascott, J., Stott, F.H. & Wood, G.C. The effectiveness of oxides in reducing sliding wear of alloys. Oxid Met 24, 99–114 (1985). https://doi.org/10.1007/BF00664227

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00664227