Conclusions

-

1.

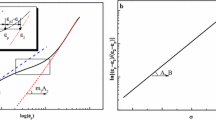

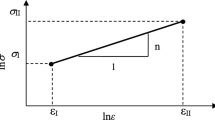

Mathematical treatment of experimental data on establishing relationships between σs and ɛ with the use of the “Nairi” computer confirmed the usefulness of the equation σs = mɛn for describing experimental hardening curves and indicates the very close relationship between σs and; the correlation coefficient is 0.935–0.993, However, for many of the investigated materials the exponential hardening rule has a somewhat approximate character, which is the result of a change in n with an increase in ɛ. This rule is best fulfilled with the use of the coefficient m and the strain-hardening exponent n determined with ɛ ≥ 1.0.

-

2.

For many metals and alloys the value of n is not a constant but changes with an increase in the degree of strain. For alloys the deformation of which is not complicated by structure and phase transformations the value of n decreases with an increase in ɛ basically up to ɛ ≈ 0.6–0.8 or remains unchanged. Of the investigated materials the value of n is constant over the whole range of considered values of ɛ for technical grade iron and 40Kh and 45Kh steels while for 35 and 18KhGT steels there is an insignificant decrease in n with an increase in ɛ. For alloys having structure and phase transformations during plastic deformation the value of n first increases with an increase in ɛ and then starts to drop.

Similar content being viewed by others

Ltteeature cited

V. A. Krokha, “The strain-hardening exponent of metals and alloys in cold plastic deformation,” in: Investigations in the Area of Plasticity and Workability of Metals by Pressure [in Russian], No. 1 (1973), pp. 74–86.

W. Panknin and S. A. Galal, “Zusammenhang zwischen Flieβkurve und Werkstoffkennwerten bildsamer metallischer Werkstoffe,” Z. Metallkunde,52, No. 7, 455 (1961).

Tavaarvek, Sauerby, and Plamitry, “Hot and cold upsetting of stainless steels,” Tr. Am. Obshch. Inzh.-Mekh., Ser. D,97, No. 2, 42–50 (1975).

Gottfried Pysz, “Zum Informationsgehalt von Flieβkurvenkenngröβen,” Neue Hütte, No. 4, 240–247 (1968).

Hein Peter Stuwe, “Die Flieβspannung bei der Kaltumformung,” Z. Metallkunde, No. 3, 180–186 (1970).

S. Schwandt. “Flieβkurven von unlegierten und legierten Stählen,” Industrie-Anzeiger,90, No. 19, 14–17 (1968).

O. B. Nizhnik and N. I. Chernyak, “Strain and structure curves of transition class stainless steels,” Probl. Prochn., No. 4, 70–73 (1974).

D. C. Ludwigson, “A modified stress-strain relationship for fcc metals and alloys,” Metalloved. Termoobrab.: Ekspress-Inf., No. 23, Ref. 58 (1972).

V. A. Krokha, “The value of hardening curves for the theory and practice of working metals by pressure,” in: Investigations in the Area of the Strength and Plasticity of Materials [in Russian], Voronezh (1978), pp. 6–12.

H. Plehn, “Von der Flieβkurve zum stichplan,“ Bergund Hüttenmänn. Monatsh., No. 3, 48–60 (1970).

V. A. Krokha, “Fundamental rules of the strengthening of metals and alloys in compression of them in the cold condition,” Kuznech.-Shtampovoch. Proiz., No. 10, 28–32 (1977).

V. A. Krokha, “A method of determining the flow stress in compression before large plastic deformations,” Zavod. Lab., No. 5, 598–601 (1974).

L. D. Sokolov and N. P. Dmitriev, “The influence of defect packing energy on the hardening exponent of metals with different crystalline lattices,” in: Some Questions of the Theory of Plastic Deformation, Proceedings of the A. A, Zhdanov Gorki Polytechnic Institute [in Russian], No. 8, Gorki (1970), pp. 4–7.

L. D. Sokolov, The Resistance of Metals to Plastic Deformation [in Russian], Metallurgizdat, Moscow (1963).

N. P. Dmitriev, “Some rules of hardening of metals with a cph structure,” in: Some Questions of the Theory of Plastic Deformation, Proceedings of the A. A. Zhdanov Gorki Polytechnic Institute [in Russian], No. 8, Gorki (1970), pp. 13–16.

G. N. Mekhed, “The rate relationship of austenitic steel flow curves,” in: Plastic Deformation of Non-standard Metallic Materials [in Russian], Moscow (1978), pp. 143–153.

M. L. Bernshtein, L. M. Kaputkina, A. M. Glushets, and E. D. Panov, “The structure of the crystalline lattice of martensite obtained by deformation of metastable 70Kh5G4 austenitic steel,” Fiz. Met. Metalloved.,46, No. 1, 121–131 (1978).

I. I. Novikov, The Theory of Heat Treatment of Metals [in Russian], Metallurgiya, Moscow (1978).

N. A. Grekov, E. P., Silina, and A. P. Surkov, “The structure and properties of explosively strengthened austenitic steels,” Izv. Akad. Nauk SSSR, Met., No. 1, 112–114 (1974).

W. Panknin, H. Fritz, and D. Materna, “Bestimmung der Formänderungsfestigkeit austeniticher Werkstoffe,” Blech Rohre. Profile, No. 11, 32–37 (1970).

A. P. Smiryagin, Industrial Nonferrous Metals and Alloys [in Russian], Metallurgizdat, Moscow (1956).

V. M. Panovko, “Determining the possibility of decomposition in deformation of metastable metals and alloys with the use of the hardening exponent,” in: Plastic Deformation of Nonstandard Metallic Materials [in Russian], Moscow (1976), pp. 122–130.

V. M. Panovko, A. M., Drits, and É. M. Semenova, “Features of the hardening of D1 alloy in deformation,” Metalloved. Term. Obrab. Met., No. 10, 46–49 (1975).

I. M. Pavlov, V. M. Panovko, and Yu. F., Tarasevich, “The use of the exponential rule of hardening of titanium alloys of different stability,” Probl. Prochn., No. 2, 83–86 (1978).

Author information

Authors and Affiliations

Additional information

Translated from Problemy Prochnosti, No. 8, pp. 72–77, August, 1981.

Rights and permissions

About this article

Cite this article

Krokha, V.A. Relationship of the strain-hardening exponent to the degree of strain and fulfillment of the exponential rule of hardening. Strength Mater 13, 1022–1027 (1981). https://doi.org/10.1007/BF00762176

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00762176