Conclusions

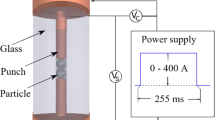

The dynamic characteristics of the process of interparticle neck formation depend not only on current density (raising the current density by 1.7 times increases interaction rates by an order) but also on the positions of the particles relative to the direction of passage of current (particles lying in a plane parallel to the direction of passage of current interact 3.4–5 times more rapidly than particles lying in a plane perpendicular to this direction). The kinetics of powder particle sintering by an electric current is due to the most intense sintering mechanisms, such as viscous flow, transport through the gaseous phase, and spreading of liquid metal over the solid surfaces of particles. The strongest influence on the kinetics of mutual particle sintering is exerted by a transport mechanism with n< 0.5. Such a mechanism may be provided by electroerosion transport in the interparticle gap.

Similar content being viewed by others

Literature cited

R. Holm and E. Holm, Electric Contacts Handbook, Springer (1958).

G. L. Burenkov and A. M. Pikuza, “Conduction channels in the sintering of metal powder particles by an electric current,” Kiev (1986), Manuscript No. 3623-V86 deposited at the All-Union Institute of Scientific and Technical Information, May 20, 1986.

D. J. Williams and W. Johnson, “Neck formation and growth in high-voltage discharge forming of metal powders,” Powder Metall.,25, No. 2, 85–90 (1982).

M. Z. Kol'chinskii and A. I. Raichenko, “A model investigation of the sintering of metal powders with intense energy release at interparticle contacts,” Poroshk. Metall., No. 8, 15–18 (1977).

Yu. V. Naidich, I. A. Lavrinenko, and V. Ya. Petrishchev, “Study on the capillary adhesive forces between solid particles with a liquid layer at the points of contact. I. Spherical particles,” Poroshk. Metall., No. 2, 50–56 (1965).

Ya. E. Geguzin, The Physics of Sintering [in Russian], Nauka, Moscow (1967).

V. V. Skorokhod and S. M. Solonin, Physicometallurgical Principles of Powder Sintering [in Russian], Metallurgiya, Moscow (1984).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 9(297), pp. 25–29, September, 1987.

Rights and permissions

About this article

Cite this article

Burenkov, G.L., Raichenko, A.I. & Suraeva, A.M. Dynamics of interparticle reactions in spherical metal powders during electric sintering. Powder Metall Met Ceram 26, 709–712 (1987). https://doi.org/10.1007/BF00797175

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00797175