Abstract

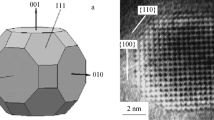

The application of the Osprey process to the fabrication of newly developed Al-20Si-X alloys is at present a subject of considerable interest. This paper reports the results of a study on the as-spray deposited structural characteristics of an Al-20Si-5Fe alloy preform and their development during subsequent hot extrusion and high-temperature exposure, by means of X-ray diffraction, differential scanning calorimetry and electron microscopy. It is shown that in the as-spray-deposited preform of the alloy an unusual increase in the lattice parameter of the aluminium matrix was detected, which persisted throughout the processing. No evidence of supersaturation in the preform aluminium matrix could be found, which is considered to be associated with the characteristics of solidification and subsequent decomposition of the hypereutectic alloy during spray deposition, this allows the extensive formation of second phases and thus a substantial decrease in the solute enrichment of the solution. A metastable intermetallic phase, identified as δ-Al4FeSi2, together with silicon phase, was present as the predominant dispersed phase in the preform, and its transformation into the equilibrium phase, β-Al5FeSi, through a peritectic reaction under the equilibrium conditions, must have been effectively suppressed during the Osprey process. The δ-phase initially with a platelet shape was fragmented into short rods during the extrusion subsequent to spray deposition, while a part of this phase was transformed into the equilibrium β-phase under the combined influence of heat and deformation. The refinement of the δ-phase, on the other hand, was found to decrease its metastability and thus to promote its decomposition during subsequent annealing at 400 °C. The coexistence of the high volume fractions of the intermetallic and silicon phases in the extruded material greatly modified its restoration kinetics, resulting in a partially recrystallized microstructure, after prolonged soaking at 400 °C for 100 H. Also shown is a peculiar microstructure of the as-spray-deposited material with numerous spherical colonies of 10–20 μm, characterized by the finer silicon particles and δ-phase platelets in their interior and occasionally decorated with micropores at their peripheries. These colonies are considered to originate from the remains of very fine droplets and particles in the larger droplets, which are presolidified in flight and then partially remelted at the deposition surface. The colonies were mixed up with the rest of the microstructure and the micropores closed by applying an extrusion operation.

Similar content being viewed by others

References

A. G. Leatham, R. G. Brooks andM. Yaman, in “Modern Developments in Powder Metallurgy”, Vol. 15 (MPIF, New Jersey, 1985) p. 157.

Osprey Metals Ltd, UK Pat. 147 239.

G. J. Marshall, in “Proceedings of the International Conference on Aluminium Technology '86”, London, March 1986, edited by T. Sheppard (The Institute of Metals, London, 1986) p. 679.

J. L. Estrada andJ. Duszczyk,J. Mater. Sci. 25 (1990) 1381.

P. Mathur, S. Annavarapu, D. Apelian andA. Lawley,J. Metals 41 (1989) 23.

E. J. Lavernia,Int. J. Rapid Solid. 5 (1989) 47.

E. J. Lavernia, E. M. Gutierrez, J. Szekely andN. J. Grant,ibid. 4 (1988) 89.

E. Gutierrez-Miravete, E. J. Lavernia, G. M. Trapaga andJ. Szekely,ibid. 4 (1988) 125.

E. Gutierrez-Miravete, E. J. Lavernia, G. M. Trapaga, J. Szekely andN. J. Grant,Metall. Trans. 20A (1989) 71.

R. W. Evans, A. G. Leatham andR. G. Brooks,Powder Metall. 28 (1985) 13.

R. H. Bricknell,Metal. Trans. 17A (1986) 583.

N. Amano, Y. Odani, Y. Takeda andK. Akechi,Metal Powder Rep. 44 (1989) 186.

J. Zhou andJ. Duszczyk, in “Hot Deformation of Aluminium Alloys”, Proceedings of the 1990 TMS Fall Meeting, “A Symposium on Hot Deformation of Aluminium Alloys”, Detroit, Michigan, USA, October 1990, edited by T. G. Langdon, H. D. Merchant, J. G. Morris and M. A. Zaidi (TMS, Warrendale, PA, 1991) p. 473.

P. Van Mourik, Th. H. De Keijser, N. M. van derPers andE. J. Mittemeijer,Scripta Metall. 22 (1988) 1547.

L. F. Monldofo, “Aluminium Alloys, Structure and Properties” (Butterworths, London, 1976) pp. 282, 759.

E. J. Mittemeijer, P. Van Mourik andTh. H. De Keijser,Phil. Mag. A 43 (1981) 1157.

S. Paidassi andJ. Chevrier, in “Rapidly Quenched Metals”, Vol. 1, Proceedings of the Fifth International Conference on Rapidly Quenched Metals, Würzburg, Germany, September 1984, edited by S. Steeb and H. Warlimont (North-Holland, Amsterdam, 1985) p. 957.

J. Zhou, J. Duszczyk andB. M. Korevaar,J. Mater. Sci. 25 (1991) 824.

H. W. L. Phillips andM. P. C. Varley,J. Inst. Metals 69 (1943) 317.

M. Van Rooyen, PhD thesis, Delft University of Technology, The Netherlands (1988).

I. Yamaunchi, I. Ohnaka, S. Kawamoto andT. Fukusako,Trans. Jpn. Inst. Metals 27 (1986) 187.

B. Badan, M. Magrini andE. Ramous,Scripta Metall. 23 (1989) 2121.

V. G. Rivlin andG. V. Raynor,Int. Metals Rev. 26 (1981) 133.

A. G. Leatham, A. J. W. Ogilvy andP. F. Chesney, in “Modern Developments in Powder Metallurgy”, Vol. 19, edited by P. U. Gummerson and D. A. Gustafson (MPIF, New Jersey, 1988) p. 475.

W. Kurz andD. J. Fisher,Int. Metals Rev. 24 (1979) 177.

B. A. Mueller, J. J. Richmond andJ. H. Perepezko, in “Rapidly Quenched Metals”, Vol. 1, Proceedings of the Fifth International Conference on Rapidly Quenched Metals, Würzburg, Germany, September 1984, edited by S. Steeb and H. Warlimont (North-Holland, Amsterdam, 1985) p. 47.

Y. Takeda, T. Hayashi, Y. Dani, N. Amono andN. Kuroishi, personal communication, Sumitomo Electric Industries Ltd, Hyogo, Japan.

K. Kobayashi, P. H. Shingu, H. Kanbara andR. Ozaki,Trans. Jpn. Inst. Metals 17 (1976) 545.

J. Zhou andJ. Duszczyk,J. Mater. Shaping Technol. 6 (1989) 241.

J. Zhou, J. Duszczyk andB. M. Korevaar,J. Mater. Sci., in press.

M. P. Anderson, in “Annealing Process — Recovery, Recrystallization and Grain Growth”, Proceedings of the 7th Risø International Symposium on Metallurgy and Materials Science, Roskilde, Denmark, September 1986, edited by N. Hansen, D. Juul Jensen, T. Leffers and B. Ralph (Risø National Laboratory, Roskilde, Denmark, 1986) p. 15.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhou, J., Duszczyk, J. & Korevaar, B.M. As-spray-deposited structure of an Al-20Si-5Fe Osprey preform and its development during subsequent processing. J Mater Sci 26, 5275–5291 (1991). https://doi.org/10.1007/BF01143222

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01143222