Abstract

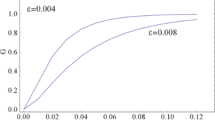

Uniaxial torsion and biaxial torsion-tension experiments on thin-walled tubes were carried out to investigate the viscoplastic behavior of stainless steel XCrNi18.9. A series of monotonic tests under strain and stress control shows nonlinear rate dependence and suggests the existence of equilibrium states, which are asymptotically approached during relaxation and creep processes. Strain controlled cyclic experiments display various hardening and softening phenomena that depend on strain amplitude and mean strain. All experiments indicate that the equilibrium states within the material depend on the history of the input process, whereas the history-dependence of the relaxation and creep behavior appears less significant. From the experiments the design of a constitutive model of viscoplasticity is motivated: The basic assumption is a decomposition of the total stress into an equilibrium stress and a non-equilibrium overstress: At constant strain, the overstress relaxes to zero, where the relaxation time depends on the overstress in order to account for the nonlinear rate-dependence. The equilibrium stress is assumed to be a rate independent functional of the total strain history. Classical plasticity is utilized with a kinematic hardening rule of the Armstrong-Frederick type. In order to incorporate the amplitude-dependent hardening and softening behavior, a generalized arc length representation is applied [14]. The introduction of an additional kinematic hardening variable facilitates consideration of additional hardening effects resulting from the non-radiality of the input process. Apart from the common yield and loading criterion of classical plasticity, the proposed constitutive model does not contain any further distinction of different cases.

The experimental data are sufficient to identify the material parameters of the constitutive model. The results of the identification procedure demonstrate the ability of the model to represent the observed phenomena with satisfactory approximation.

Similar content being viewed by others

References

Rott, U.: Ein neues Konzept zur Berechnung viskoplastischer Strukturen, Dissertation Bochum, Mitteilungen aus dem Institut für Mechanik 76 (1991)

Chaboche, J. L.: Constitutive Equations for Cyclic Plasticity and Cyclic Viscoplasticity, International Journal of Plasticity, 5 (1989), 247–302

Hart, E.: Constitutive Equations for Non-Elastic Deformation, Nuclear Engineering and Design 46 (1978) 179–185

Krempl, E., McMahon, J., Yao, D.: Viscoplasticity Based on Overstress with a Differential Growth Law for the Equilibrium Stress, Mechanics of Materials 5 (1986), 35–48

Walker, K. P.: Research and Developement Program for Nonlinear Modeling with Advanced Time-Temperature Constitutive Relationships, United Technologies Research Center, East Hartford, Connecticut, USA, Report NASA CR-165533 (1983)

Korzen, M.: Materialgleichungen der Viskoplastizität-Vergleichende Darstellung und Diskussion, Deutsche Forschungsgemeinschaft - Abschlussbericht (1991)

Sütcü, M., Krempl, E.: A Stability Analysis of the Uniaxial Viscoplasticity Theory Based on Overstress, Computational Mechanics 4 (1989), 401–408

Ohno, N., Kachi, Y.: A Constitutive Model of Cyclic Plasticity for Nonlinear Hardening Materials, Journal of Applied Mechhanics 53 (1986), 395–403

Haupt, P., Korzen, M.: On the Mathematical Modeling of Material Behavior in Continuum Mechanics, Advances in Constitutive Laws for Engineering Materials (1989), F. Jinghong, S. Marakami, Chongqing, China, Pergamon Press Kronberg, 456–459

Krempl, E.: Models of Viscoplasticity – Some Comments on Equilibrium (Back) Stress and Drag Stress, Acta Mechanica 69 (1987), 25–42

Tsou, J. C., Quesnel, D. J.: Internal Stress Measurements during the Saturation Fatigue of Polycrystalline Aluminium, Materials Science and Engineering 56 (1982), 289–299

Armstrong, P .J., Frederick, C. O.: A Mathematical Representation of the Multiaxial Bauschinger Effect, G.E.G.D. Report RD/D/N 731 (1966)

Chaboche, J. L.: Time-Independent Constitutive Theories for Cyclic Plasticity, International Journal of Plasticity 2 (1986), 149–188

Haupt, P., Kamlah, M., Tsakmakis, Ch.: Continuous Representation of Hardening Properties in Cyclic Plasticity, International Journal of Plasticity 8 (1992), 803–817

Benallal, A., Marquis, D.: Constitutive Equations for Nonproportional Cyclic ElastoViscoplasticity, Journal of Engineering Materials and Technology 109 (1987), 326–336

Haupt, P., Schreiber, L., Lion, A.: Experimentelle Untersuchung des geschwindigkeitsabhängigen Materialverhaltens bei nichtradialen Belastungen, ZAMM 73 (1993) 4–5, T325–T325

Schreiber, L.: Parameteridentifikation bei Stoffmodellen mit der Evolutionsstrategie, ZAMM 73 (1993) 4–5, T343–T345

Schreiber, L.: Ein Stoffgesetz für nichtradiale Prozesse, ZAMM 68 (1988) 4, T255–T257

Krempl, E., Lu, H.: The Hardening and Rate-Dependent Behavior of Fully Annealed AISI 304 Stainless Steel under Biaxial Cycling at Room Temperature. Journal of Engineering Materials and Technology (1984), Vol. 106, 376–382

Chaboche, J. L., Dang Van, K., Cordier, G.: Modelization of the Strain Memory Effect on the Cyclic Hardening of 316 Stainless Steel. Transactions of the 5th International Conference on Structural Mechanics in Reactor Technology, Berlin 1979, North - Holland Publishing Company for the Comission of the European Communities

Valanis, K. C.: A Theory of Viscoplasticity Without a Yield Surface, Part 2. Archives of Mechanic (1971), 23, 4, 535–551

Tanaka, E., Murakami, S., Oaka, M.: Effects of Plastic Strain Amplitudes on Non — proportional Cyclic Plasticity. Acta Mechanica 57, (1985), 167–182

Krempl, E., Choi, S. H.: Viscoplasticity Based on Overstress: The Modeling of Ratchetting and Cyclic Hardening of AISI Type 304 Stainless Steel. Mechanics of Materials Laboratory, Rensselaer Polytechnic Institute, Troy, NY 12180–3590, RPI Report MML 90–4, 1990

Bruhns, O. T., Lehmann, Th., Pape, A.: On the Description of Transient Cyclic Hardening Behaviour of Mild Steel Ck 15, International Journal of Plasicity 8 (1992), 331–359

Kikillus, U.: Ein Beitrag zum zyklischen Kriechverhalten von Ck 15, Dissertation Bochum, Mitteilungen aus dem Institut für Mechanik 84, 1993

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Haupt, P., Lion, A. Experimental identification and mathematical modeling of viscoplastic material behavior. Continuum Mech. Thermodyn 7, 73–96 (1995). https://doi.org/10.1007/BF01175770

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01175770