Abstract

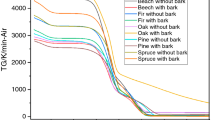

Analytical methods that predict the endurance of structural wood members in a fire are based on the reduction of the cross section of the member caused by wood being charred. To define the charring rate in terms of more fundamental properties, empirical models were established. Eight species were tested for charring rates and material properties. Regression analysis was used to develop the models. The predictor variables for the initial factorial design included density, moisture content, treatability, and hardwood-softwood classification. The addition of char contraction simplified the model and reduced the predictor variables to the char contraction factor, density, and moisture content. Our results show the importance of surface recession and moisture content to wood charring.

Similar content being viewed by others

Abbreviations

- a :

-

empirical parameter

- b :

-

empirical parameter

- c :

-

hardwood (−1)-sofwood (+1) classification

- d :

-

depth of penetration in treatability test, mm

- e :

-

error in estimate, min

- f c :

-

char contraction factor, dimensionless

- g :

-

empirical parameter

- m :

-

reciprocal of charring rate as defined by Equation (8), min/mm

- p :

-

density from oven-dry mass and volume, g/cm3

- R :

-

correlation coefficient, dimensionless

- t :

-

time, min

- u :

-

moisture content, percent

- x c :

-

char depth from original fire-exposed surface, mm

- Z 1 :

-

empirical parameter with coefficient of 1 in Equation (11)

References

“Standard Methods of Fire Tests of Building Construction and Materials.” Designation E 119-83, American Society for Testing and Materials, Philadelphia, PA, 1983.

White, Robert H., “Analytical Methods for Determining Fire Resistance of Timber Members.” In:SFPE Handbook of Fire Protection Engineering, National Fire Protection Association, Quincy, MA, 1988.

Atreya, Arvind, “Pyrolysis, Ignition and Flame Spread on Horizontal Surfaces of Wood.” Ph. D. diss., Harvard University, Cambridge, MA, 1983.

Fredlund, Bertil, “A Model for Heat and Mass Transfer in Timber Structures during Fires.” Institute of Science and Technology, Department of Fire Safety Engineering, Lund University, Lund, Sweden, Report LUTVDG/(TV BB. 1003), 1988.

Hadvig, Sven, “Charring of Wood in Building Fires.” Laboratory of Heating and Air-Conditioning, Technical University of Denmark, Lyngby, Denmark, 1981.

Parker, William J., “Prediction of the Heat Release Rate of Wood.” Ph. D. diss., George Washington University, Washington, DC, 1988.

White, Robert Hawthorne, “Charring Rates of Different Wood Species.” Ph. D. diss., University of Wisconsin, Madison, WI, 1988.

Kanury, Murty A. and Blackshear, Perry L. Jr., “Some Considerations Pertaining to the Problem of Wood-Burning.”Combustion Science and Technology, 1 (1970): 339–356.

Lee, Calvin K., Chaiken, Robert F., and Singer, Joseph M., “Charring in Pyrolysis of Wood in Fires by Laser Simulation.” In:Sixteenth Symposium (Int.) on Combustion, pp. 1459–1470, The Combustion Institute, Pittsburgh, PA, 1977.

Bryan, J., and Doman, J.S., “Fire Resistance — The Comparative Resistance to Fire of Various Species of Timber”.Wood, 5 (1940): 19–23.

McNaughton, G.C., “Comparative Performance of Different Species of Untreated Wood in Various Fire-Test Methods.” U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, WI, 1942.

Thomas, P.H., and Simms, D.L., and Law, Margaret, “The Rate of Burning of Wood.” Fire Research Note No. 657, Fire Research Station, Borehamwood, England, 1967.

Schaffer, E.L., “Charring Rate of Selected Woods—Transverse to Grain” Research Paper FPL 69, U.S. Department of Agriculture, Forest Products Laboratory, Madison, WI, 1967.

Rogowski, Barbara, “Charring of Timber in Fire Tests.” In:Fire and Structural Use of Timber in Buildings, Fire Research Station Symposium No. 3, London: HMSO, 1970.

Hall, G.S., Saunders, R.G., Allcorn, R. T., Jackman, P.E., Hickey, M.W., and Fitt, R., “Fire Performance of Timber—A Literature Survey.” Timber Research and Development Association, High Wycombe, England, 1972.

Williams, C.C., “Damage Initiation in Organic Materials Exposed to High Intensity Thermal Radiation.” Ph. D. diss., Massachusetts Institute of Technology, Cambridge, MA, 1953.

Dorn, H., and Egner, K., “Fire Tests on Glued Laminated Structural Timbers (Glulam Beams).” Translated by D.A. Sinclair. Technical TranslationNo. 1131, Ottawa: National Research Council of Canada. Trans. of “Brandversuche mit geleimten Holzbauteilen (Hetzer-Balken),”Holz-Zentralblatt, 28 (1964): 435–438.

White, Robert H., and Schaffer, E.L., “Transient Moisture Gradient in Fire-Exposed Wood Slab.”Wood and Fiber, 13 (1981): 17–38.

Tinney, E. Roy., “The Combustion of Wooden Dowels in Heated Air.” In:Tenth Symposium (Int.) on Combustion 925–930, The Combustion Institute, Pittsburgh, PA, 1965.

Roberts, A.F., “A Review of Kinetics Data for the Pyrolysis of Wood and Related Substances.”Combustion and Flame, 14 (1970): 261–272.

Tang, W.K., “Forest Products.” In:Differential Thermal Analysis, edited by R.C. Mackenzie, Vol. 2. Applications, 523–553. Academic Press, New York, NY, 1972.

Knudson, R.M., and Williamson, R.B., “Influence of Temperature and Time Upon Pyrolysis of Untreated and Fire Retardant Treated Wood.”Wood Science and Technology, 5 (1971): 176–189.

Hadvig, Sven, and Paulsen, O.R., “One-Dimensional Charring Rates in Wood.”J. Fire and Flammability, 7 (1976): 433–449.

White, Robert H., and Schaffer, E.L., “Application of CMA Program to Wood Charring.”Fire Technology, 14 (1978): 279–290, 296.

Roberts, A.F., “The Heat of Reaction During the Pyrolysis of Wood.”Combustion and Flame, 17 (1971): 79–86.

Snedecor, George W., and Cochran, William G.,Statistical Methods, 7th ed, The Iowa State University Press, Ames, IA, 1980.

Lawson, D.E., Webster, C.T., and Ashton, L.A., “The Fire Endurance of Timber Beams and Floors.”Structural Engineer, 30 (1952): 27–33.

Vorreiter, Leopold, “Combustion and Heat Insulating Losses of Wood and Fiber Boards.” Translated by Research Information Service, Translation No. 321, Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. Trans. of “Abbrandverlust und Temperaturdammung von Holz und Holzwerkstoffen,”Holzforschung, 10 (1956): 75–80.

Kanury, Murty A., and Holve, Donald J., “A Theoretical Analysis of the ASTM E 119 Standard Fire Test of Building Construction and Materials.” National Bureau of Standards, Washington, DC, NBS-GCR 76-50, 1975.

Draper, N.R. and Smith, H.,Applied Regression Analysis, 2nd ed. New York, NY, John Wiley & Sons, 1981.

Tenning, K., “Glued Laminated Timber Beams: Fire Tests and Experience in Practice.” In:Fire and Structural Use of Timber in Buildings, Symposium No. 3, Fire Research Station, London: HMSO, 1970.

Parker, William J., “Development of a Model for the Heat Release Rate of Wood—A Status Report.” National Bureau of Standards, Gaithersburg, MD, Report NBSIR 85-3163, 1985.

Beall, F.C., “Properties of Wood During Carbonization Under Fire Conditions.” In:Wood Technology: Chemical Aspects, edited by Irving S. Goldstein, Washington, DC: American Chemical Society, 1977.

Evans, D.D., “Density of Wood Charcoal.” Cambridge, MA: Harvard University, Home Fire Project Technical Report No. 14 1975.

Slocum, D.H., McGinnes, E.A., Jr., and Beall, F.C., “Charcoal Yield, Shrinkage, and Density Changes During Carbonization of Oak and Hickory Woods.” Wood Science, 11, (1978): 42–47.

Truax, T. R., “Fire Research and Results at the Forest Products Laboratory.” Report No. 1999, U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, WI, 1959.

Malhotra, H.L., “Design of Fire-Resisting Structures.” Chapman and Hall (Surrey University Press), New York, NY, 1982.

Jansen, A., Pizzi, A., and Conradie, W.E., “The Penetration Characteristics of CCA Preservatives in Wood-Radial/Tangential, Processes and Species Effects.”Holz als Roh- und Werkstoff, 43, (1985): 181–186.

Author information

Authors and Affiliations

Additional information

The Forest Products Laboratory is maintained in cooperation with the University of Wisconsin. This article was written and prepared by U.S. Government employees on official time, and it is therefore in the public domain and not subject to copyright.

Rights and permissions

About this article

Cite this article

White, R.H., Nordheim, E.V. Charring rate of wood for ASTM E 119 exposure. Fire Technol 28, 5–30 (1992). https://doi.org/10.1007/BF01858049

Issue Date:

DOI: https://doi.org/10.1007/BF01858049