Abstract

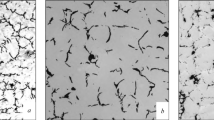

Measurements have been made on the ultimate strength, yield stress, endurance limit with and without stress concentrators, and oscillation decrement for cast iron containing spheroidal graphite and alloyed (in mass %) with 0.30–1.08 Mn, 0–0.81 Cu, 0.45–0.62 Ni, and 0–0.32 Mo and having structures of ferrite, pearlite, bainite, and bainite-ferrite types (with 25–30% ferrite) and also martensite structure. Concentrations of those elements have been determined that provide the best combination of static and dynamic characteristics. The effects of the alloying elements on the properties of the cast iron have been related to the structure of the metal substrate. In particular, in pearlitic cast iron alloyed with 0.7–0.8% Cu, 0.4–0.5% Ni, 0.3% Mn, the addition of Mo is ineffective, while in cast iron having the bainite structure, that element raises the yield stress and the fatigue strength even in the absence of Cu, while the sensitivity to stress concentration is reduced.

Similar content being viewed by others

References

I.A. Oding, Permissible Stresses in Engineering and the Cyclic Strengths of Materials [in Russian], Mashgiz, Moscow (1962), 260 pp.

V. T. Troshchenko, Fatigue and Inelasticity in Metals [in Russian], Naukova Dumka, Kiev (1971), 268 pp.

V. I. Litovka, A. A. Snezhko, A. P. Yakovlev, et al., The Cyclic Viscosity of Cast Iron [in Russian], Naukova Dumka, Kiev (1973), 168 pp.

V. I. Litovka, Improving the Quality of High-Strength Cast Iron in Castings [in Russian], Naukova Dumka, Kiev (1987), 208 pp.

N. I. Bekh, “Developing the technology and installing the production of high-strength cast iron at the KamAZ casting plant,” Liteinoe Proiz., No. 4, 12–13 (1983).

N. N. Afabas'ev, The Statistical Theory of Alloy Fatigue Strength [in Russian], Izd. AN Ukr. SSR, Kiev (1953), 128 pp.

M. E. Garf (ed.), Machines and Instruments for Programmed Fatigue Testing [in Russian], Naukova Dumka, Kiev (1970), 195 pp.

L. A. Bocharova and G. S. Pisarenko, “The D-7 apparatus for researching imperfect elasticity in materials,” in: Thermal Strength in Materials and Constructional Components [in Russian], Naukova Dumka, Kiev (1965), pp. 176–181.

V. I. Litovka, N. I. Bekh, and G. A. Kosnikov, “Fatigue strength and failure in cast iron containing spheroidal graphite,” Liteinoe Proiz., No. 6, 3–5 (1994).

V. I. Litovka, N. I. Bekh, V. Ya. Bikerniek, et al., “Dynamic strength in high-strength cast iron for automobile components,” Avtomob. Prom., No. 9, 27–28 (1981).

Author information

Authors and Affiliations

Additional information

Translated from Problemy Prochnosti, No. 8, pp. 30–37, August, 1995.

Rights and permissions

About this article

Cite this article

Litovka, V.I., Bekh, N.I., Shinskii, O.I. et al. Effects of composition and structure on the state, fatigue, and damping properties of high-strength cast iron. Strength Mater 27, 448–453 (1995). https://doi.org/10.1007/BF02209340

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02209340