Abstract

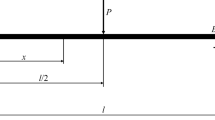

A special strain gage called the ‘shear gage’ was developed for composite materials testing with notched shear specimens. The shear-gage records the average shear strain across the entire test section between the notches of the losipescu and compact shear specimens rather than just sampling the shear strain over a small region in the center of the test section. Hence, the shear stress/strain response is obtained by dividing the average shear stress (load divided by the cross-sectional area between the notches) by the average shear strain. By placing gages on both faces of the specimen, accurate and repeatable shear-modulus measurements can be made without prior knowledge of the shear strain or stress distributions. This scheme essentially integrates the shear strain through the entire test section. Knowledge of other material properties is not required to accurately determine shear modulus values. The shear gage was tested on a variety of composite and isotropic materials resulting in more reliable shear modulus determination and less scatter than previously possible.

Similar content being viewed by others

References

Iosipescu, N., “New Accurate Method for Single Shear Testing of Metals,”J. Mat.,2, (3),537–566 (Sept.1967).

Adams, D.F. andWalrath, D.E., “The Iosipescu Test as Applied to Composite Materials,”Experimental Mechanics,23 (1),105–110 (March1983).

Adams, D.F. andWalrath, D.E., “Current Status of the Iosipescu Shear Test Method,”J. Comp. Mat.,21,494–507 (1987).

Lee, S. andMunro, M., “Evaluation of In-Plane Shear Testing for Composite Materials by the Decision Analysis Technique,”Comp.,17 (1),13 (Jan.1986).

Wilson, D.W., “Evaluation of the V-Notched Beam Shear Test Through an Interlaboratory Study,” ASTM Subcommittee D30.03 Report (1990).

Herakovich, C.T., and Bergner, H.W., “Finite Element Stress Analysis of a Notched Coupon Specimen for In-Plane Shear Behavior of Composites,” Comp., 149–154 (July 1980).

Walrath, D.E., and Adams, D.F., “Analysis of the Stress State in an Iosipescu Shear Test Specimen,” Rep. UWME-DR-301-102-1, Dept. of Mech. Engi., Univ. of Wyoming, NASA Grant NAG-1-272 (June 1983).

Ho, H., Tsai, J. Morton, J. andFarley, G.L., “Experimental Investigation of the Iosipescu Specimen for Composite Materials,Experimental Mechanics,31 (4),328–336 (Dec.1991).

Pindera, M.-J., Ifju, P.G. andPost, D., “Iosipescu Shear Characterization of Polymeric and Metal Matrix Composites,”Experimental Mechanics,30, (1),101–108 (1990).

Sullivan, J.L. and Blais, E.J., “Composite Shear Properties from Iosipescu Specimens”, to be published in J. Comp. Mat.

Wang, S.S. and Dasgupta, A., “Development of Iosipescu-Type Test for Determining In-Plane Shear Properties of Fiber Composite Materials: Critical Analysis and Experiment,” Rep. No. UILU-ENG-86-5021, Dept. TAM and Aeronautical and Astronautical Eng., Univ. of Illinois (1986).

Pindera, M.J., Choksi, G.N., Hidde, J.S., and Herakovich, C.T., “A methodology for Accurate Shear Characterization of Unidirectional Composites,” ASTM STP 734, Amer. Soc. for Test. and Mat., 129–151 (1981).

Ifju, P.G. and Post, D., “A Compact Double Notched Specimen for In-Plane Shear Testing”, Proc. 1989 SEM Spring Conf. on Exp. Mech. (May 1989).

Abdallah, M.G., Gardiner, D.S. and Gascoigne, H.E., “Evaluation of Graphite/Epoxy Iosipescu Shear Specimen Testing Methods with Optical Techniques,” 1985 Proc. SEM Spring Conf. on Exp. Mech. (June 1985).

Abdallah, M.G., andGascoigne, H.E., “Influence of Test Fixture Design on the Iosipescu Shear Test for Fiber Composite Materials,”Test Methods and Design Allowables for Fibrous Composites: 2nd Volume, STP 1003, ed. C.C. Chamis Amer. Soc. for Test. and Mat., Philadelphia 231–260 (1989).

Ifju P.G., and Post, D., “A Special Strain Gage for Shear Testing of Composite Materials,” Proc. 1991 SEM Spring Conf. on Exp. Mech. (June 1991).

Ifju, P.G., “Evaluation of a New Electrical Resistance Shear Strain Gage Using Moire Interferometry,” Proc. SPIE Conf. on Photomechanics (Aug. 1991).

“Strain Gages for Shear Modulus Testing of Composite Materials,” Micro-Measurements Division, Measurements Group, Inc., Supplimental Data Sheet for Strain Gage Catalogue (1992).

Perry, C.C. andLissner, H.R., The Strain Gage Primer, McGraw-Hill, New York (1955).

Ifju, P.G. and Post, D., “The Shear Gage and Compact Shear Specimen for Shear Property Measurements of Composite Materials,” Virginia Polytechnic Instit. and State Univ., Center for Composite Materials and Structures Report Series, CCMS-92-19 (1992).

Post, D., Han, B., Ifju, P.G., High Sensitivity Moire: Experimental Analysis for Mechanics and Materials, Springer-Verlag, New York (1994).

Guo, Y. andIfju, P.G., “A Practical Moiré Interferometry System for Testing Machine Applications,”Exp. Tech.,15, (1),29–31 (1991).

Boyer, H.E. and Gall, T.L., Metals Handbook Desk Edition, Amer. Soc. for Metals, section 2.16 (1985).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ifju, P.G. The shear gage: For reliable shear modulus measurements of composite materials. Experimental Mechanics 34, 369–378 (1994). https://doi.org/10.1007/BF02325152

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02325152