Abstract

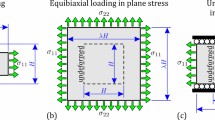

A new experimental technique for imposing controlled lateral confinement on specimens subjected to dynamic uniaxial compression has been developed. A description of the experimental technique and experimental results on a ceramic are presented. The axial compression is applied by a split Hopkinson pressure bar modified to subject the specimen to a single loading pulse during the experiment. The specimen is confined laterally by a shrink-fit metal sleeve. The results show that the failure occurs by fragmentation due to axial splitting under uniaxial stress condition, whereas failure occurs by localized deformation on faults under moderate lateral confinement. The compressive failure strength of the ceramic increases with increasing confinement pressure.

Similar content being viewed by others

References

Heard, H. C. andCline, C. F., “Mechanical Behavior of Polycrystalline BeO, Al 2 O 3 and AIN at high pressure,”J. Mat. Sci.,15 (8),1889–1897 (1980).

Horii, H. andNemat-Nasser, S., “Brittle Failure in Compression: Splitting, Faulting and Ductile-Brittle Transition,”Phil. Trans. Roy. Soc. London,319 (1549),337–374 (1986).

Ashby, M. F. andSammis, C. G., “The Damage Mechanics of Brittle Solids in Compression,”Pure Appl. Geophys.,133 (3),489–521 (1990).

Arrowood, R. andLankford, J., “Compressive Fracture Processes in an Alumina-Glass Composite,”J. Mat. Sci.,22 (10),3737–3744 (1987).

Lankford, J., “Compressive Strength and Microplasticity in Polycrystalline Alumina,”J. Mat. Sci.,12 (4),791–796 (1977).

Raiser, G. andClifton, R. J., “High-Strain Rate Deformation and Damage in Ceramic Materials,”J. Eng. Mat.,115 (3),292–299 (1993).

Lindholm, U. S., “Some Experiments with the Split Hopkinson Pressure Bar,”J. Mech. Phys. Solids,12 (3),317–335 (1964).

Follansbee, P., “The Hopkinson Bar,”Mechanical Testing, Metals Handbook, vol. 8, 9th ed., American Society for Metals, Metals Park, OH, 198–217 (1985).

Ravichandran, G., andChen, W., “Dynamic Failure of Brittle Material under Uniaxial Compression,”Experiments in Micromechanics of Failure Resistant Materials, AMD vol. 130 ed. K. S. Kim, ASME, New York, 85–90 (1991).

Chen, W. andRavichandran, G., “Static and Dynamic Compressive Behavior of Aluminum Nitride under Lateral Confinement,”J. Am. Ceram. Soc.,79 (3),579–584 (1996).

Chen, W., Subhash, G. andRavichandran, G., “Evaluation of Ceramic Specimen Geometries Used in the Split Hopkinson Pressure Bar,”DYMAT J.,1 (3),193–210 (1994).

Olsson, W. A. and Forrestal, M. J., work in progress.

Bhushan, B. andJahsman, W. E., “Measurement of Dynamic Material Behavior under Nearly Unaxial Strain Condition,”Int. J. Solids and Structures,14 (9),739–753 (1978).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chen, W., Ravichandran, G. An experimental technique for imposing dynamic multiaxial-compression with mechanical confinement. Experimental Mechanics 36, 155–158 (1996). https://doi.org/10.1007/BF02328712

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02328712