Abstract

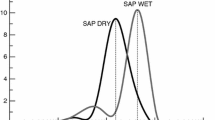

The four components of Portland cement; dicalcium silicate (Ca2SiO4), tricalcium silicate (Ca3SiO5), tricalcium aluminate (Ca3Al2O6), and tetracalcium aluminate iron oxide (Ca4Al2Fe3O10), were made by the PVA complexation process. Powders prepared by this new method can make relatively high yields of pure, synthetic, cement components of nano or sub-micron crystallite dimensions, high specific surface area, and extremely high reactivity at relatively low calcining temperatures in comparison with conventional methods. The above advantages can enhance setting speed, increase strength, and lead to other desirable characteristics of Portland cement. Optimum synthesis conditions, such as PVA content, degree of polymerization of the PVA, and calcination temperature, were determined for each component. Hydration speed and strength of the synthesized, mixed cement paste were also studied at room temperature (25°C). The powders and hydration behavior were characterized by microstructural examination (XRD, SEM) and specific surface areas were measured by nitrogen gas adsorption BET. DSC and Instron were used to study setting speed and compression strength.

Résumé

Les quatre élément constituant le ciment Portland: le silicate dicalcique (Ca2SiO4), le silicate tricalcique (Ca3SiO5), l'aluminate tricalcique (Ca3Al2O6), et l'aluminoferrite tétracalcique (Ca4Al2Fe3O10) ont été préparés par la méthode de complexation par piégeage par des molécules de PVA. Les poudres préparées par cette nouvelle méthode donnent des rendements relativement élèves de constituants purs, synthétiques avec une taille de grains nano ou submicronique, une surface spécifique élevée et une réactivité extrêmement forte à des températures de frittage relativement basses, en comparaison avec les méthodes conventionnelles. Les avantages ci-dessus peuvent permettre de réduire le coût de production du ciment Portland, d'augmenter la résistance, et de mener à d'autres caractéristiques dèsirables. Les conditions optimales de synthèse, telles que la quantité de PVA, le degré de polymérisation du PVA, et la température de frittage, ont été déterminées pour chaque constituant. La vitesse d'hydratation et la résistance de la pâte pure mélangée, ont aussi été étudiées à température ambiante (25°C). Les poudres, et le déroulement de l'hydratation ont été caractérisés par examen des microstructures (diffraction des RX, MEB) et les surfaces spécifiques ont été mesurées par absorption BET de diazote. La vitesse de prise et la résistance en compression ont été étudiées par DSC et dynamomètre Instron.

Similar content being viewed by others

References

Tai, L.W. and Lessing, P.A., ‘Modified resin-intermediate processing of perovskite powders’,J. Mater. Res. 7 (1992) 502–510.

Nettleship, I., Shull, J.L. and Kriven, W.M., ‘Chemical preparation and phase stability of Ca2SiO4 and Sr2SiO4 powders’,J. Euro. Ceram. Soc. 2 (1993) 291–298.

Gülgün, M.A., Popoola, O.O. and Kriven, W.M., ‘Chemical synthesis and characterization of calcium aluminate powders’,J. Am. Ceram. Soc. 77 (1994) 531–539.

Praminik, P. and Pathak, A., ‘A new chemical route for the preparation of fine particles of mixed oxide systems’,Mater. Sci. Bull. 17 (1994) 967–975.

Kingsley, J.J., Schilling, C.H. and Adair, J.H., ‘Ceramic Transactions’V. 62 (The American Ceramics Society, Ohio 1995).

Fumo, D.A., Morelli, M.R. and Segadaes, A.M., ‘Combustion synthesis of calcium aluminates’,Mater. Res. Bull. 31 (1996) 1243–1255.

Nguyen, M.H., ‘A new polymer route to the synthesis of mixed oxide ceramics’, M.S. Thesis; University of Illinois at Urbana-Champaign, 1997.

Lee, S.J. and Kriven, W.M., ‘Crystallization and densification of nano-size, amorphous cordierite powder prepared by PVA solution-polymerization route’,J. Am. Ceram. Soc. 81 (1998) 2605–2612.

Gülgün, M.A., Nguyen, M.H. and Kriven, W.M., ‘Polymerized organic-inorganic synthesis of mixed oxides’,J. Am. Ceram. Soc. 82 (1999) 556–560.

Nguyen, M.H., Lee, S.J. and Kriven, W.M., ‘Synthesis of oxide powders via a polymeric steric entrapment precursor route’,J. Mater. Res. 14 (1999) 3417–3426.

Lee, S.J., Benson, E.A. and Kriven, W.M., ‘Preparation of Portland cement components by poly (vinyl alcohol) solution polymerization’,J. Am. Ceram. Soc. 82 (1999) 2049–2055.

Lee, S.J., Biegalski, M.D. and Kriven, W.M., ‘Powder synthesis of barium titanate and barium orthotitanate via an ethylene glycol complexation polymerization route’,J. Mater. Res. 14 (1999) 3001–3006.

Kralj, D., Matkovic, B., Taylor, R., Young, J.F. and Chan, C.J., ‘Preparation of dicalcium silicate at 950°C’,J. Am. Ceram. Soc. 69 (1986) C170-C172.

Roy, D.M. and Oyfesobi, S.O., ‘Preparation of very reactive Ca2SiO4 powder’,J. Am. Ceram. Soc. 60 (1997) 178–180.

Odler, I. and Koster, H., ‘Investigation of the structure of fully hydrated Portland cement and tricalcium silicate pastes’,Cem. Concr. Res. 21 (1991) 975–982.

Portland Cement Association, ‘Portland cement: past and present characteristics’,Concr. Technol. Today 17 (1996) 1–4.

Munoz, M.V., Garcia, F.G., Rodriguez, M.G., Vilchez, M.C.G. and Hudson, S., ‘Influence of the mineralogical composition, specific surface area and strains’,Cem. Concr. Res. 25 (1995) 1103–1110.

Taylor, H.F.W., ‘Cement Chemistry’ (Academic, London, 1990).

Sasaki, K., Ishida, H., Okada, Y. and Mitsuda, T., ‘Highly reactive beta-dicalcium silicate’,J. Am. Ceram. Soc. 76 (1993) 870–874.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, S.J., Kriven, W.M. Synthesis and hydration study of Portland cement components prepared by the organic steric entrapment method. Mat. Struct. 38, 87–92 (2005). https://doi.org/10.1007/BF02480579

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02480579