Abstract

The direct tensile strength of silica fume cement paste and mortar were evaluated at various water-cementitious content ratios. Four different water-cementitious content ratios of 0.22, 0.25, 0.28, and 0.31 were used, and three contents of silica fume, 8%, 16%, and 25% by mass of cement. Superplasticizer content was adjusted for each mix to ensure that no segregation would occur.

Results show that partial replacement of cement by 8% of silica fume resulted in an increase in the tensile strength of mortar, but showed no effect on the tensile strength of cement paste. The replacement of cement by a higher dosage of silica fume (16 and 25%) resulted in a decrease in the tensile strength of both cement paste and mortar. However, this reduction was higher in cement paste than in mortar. It was also demonstrated that superplasticizer in combination with silica fume plays a more effective role in mortar than in paste mixes. This can be attributed to a more efficient utilization of superplasticizer in the mortar mixes due to better dispersion of the silica fume particles.

The direct tensile strength was evaluated using a new hydraulic tensile testing technique. The technique measures the intrinsic tensile strength of the cement-based composites by producing a uniform tensile stress along the length of the specimen, and thus minimizes misalignment and stress concentration at gripping. A brief description of this technique is presented in this paper.

Résumé

La résistance à la traction directe de la pâte de ciment-fumée de silice et de mortier a été évaluée pour différents rapports eau/ciment. Quatre rapports eau/ciment ont été utilisés, 0,22, 0,25, 0,28, 0,31, avec un dosage de fumée de silice en pourcentage de ciment de 8%, 16%, et 25%. Pour chaque formulation, le dosage du superplastifiant a été ajusté afin d'éviter la ségation.

Les résultats ont montré qu'un remplacement partiel de timent de 8% de fumée de silice engendre une augmentation de la résistance à la traction du mortier, mais aucun effet sur la résistance à la traction de la pâte de ciment. Le remplacement de ciment par un important dosage de fumée de silice (16% et 25%) résulte une diminution de la résistance à traction du mortier ainsi que la pâte du ciment. Cette diminution a été plus importante dans le cas de ciment que dans celui du mortier. Il est aussi démontré que l'utilisation du superplastifiant avec fumée de silice joue un rôle plus efficace dans le mortier que dans la pâte de ciment. Cela peut être attribué à une meilleure dispersion des particules de fumée de silice dans le mortier.

La résistance à la traction directe à été déterminée en utilisant un nouveau système hydraulique «hydraulique tensile testion technique». Cette technique permet de mesurer la contrainte intrinsèque de traction du composite en exerçant une contrainte de traction uniforme le long de l'éprouvette, qui permet de minimiser la concentration des contraintes à l'ancrage de l'éprouvette. Cette nouvelle technique est décrite dans cet article.

Similar content being viewed by others

References

Carette, G. G. and Malhotra, V. M., ‘Mechanical properties, durability, and drying shrinkage of Portland cement concrete incorporating silica fume’,Cement, Concrete, and Aggregates, CCAGDP 5 (3) (1983) 3–13.

Cohen, M. D. and Bentur, A., ‘Durability of Portland cementsilica fume pastes in magnesium sulfate attack and sodium sulfate solution’,ACI Materials Journal,85 (3) (1988) 148–157.

Nagataki, S., ‘Mineral Admixtures in Concrete: State of the Art and Trends’, Proceedings on Concrete Technology: Past, Present, and Future, SP-144, American Concrete Institute, Detroit, Mich., (1994) 447–464.

Xie, J., Elwi, A. E. and MacGregor, J. G., ‘Mechanical properties of three high-strength concretes containing silica fume’,ACI Materials Journal 92 (2), (1995) 135–145.

Yogendran, V., Langan, B. W., Haque, M. N. and Ward, M. A., ‘Silica fume in high strength concrete’,84 (2) (1987) 124–129.

Goldman, A. and Bentur, A., ‘The Influence of microfiller on enhancement of concrete strength’,Cement and Concrete Research Journal 23 (4) (1993) 962–972.

Scrivener, K. L.,et al., ‘Quantitative characterization of the transition zone in high strength concrete’,Advances in Cement Research 1 (4) (1988) 230–237.

Alexander, M. G.,et al., ‘The Influence of Rock and Cement Types on the Fracture Properties of the Interfacial Zone’, Interfaces in Cementitious Composites, Ed. J. C. Maso, E&F.N. Spon, London, (1992) 129–137.

Qu, L. and Mindess S., ‘Effect of Silica Fume Addition on the Fracture of Cement Paste, Paste/Rock Interfaces, and Mortar’, Proceedings 3rd Canadian Symposium in Cement and Concrete, Ottawa, (1993) 176–176.

Mindess, S., Qu, L. and Alexander, M. G., ‘The influence of silica fume on the fracture properties of paste and microconcrete’,Advances in Cement Research 6 (23) (1994), 103–107.

FIP, Condensed Silica Fume in Concrete Thomas Telford, London, 1988.

Muguruma, H. and Watanable, f., ‘Ductility Improvement of High Strength Concrete Columns with Lateral Confinement’, Proceedings 2nd International Symposium on High Strength Concrete, Ed. W. T. Hester, SP-121, American Concrete Institute, Detroit, (1990) 47–61.

Shin, S.-W.,et al., ‘Flexural Ductility, Strength Prediction, and Hysteretic Behavior of Ultra-High-Strength Concrete Members’, in Proceedings 2nd International Symposium on High-Strength concrete, Ed W. T. Hester, SP-121, American Concrete Institute, Detroit, (1990) 239–265.

Bentur, A. and Cohen, M. D., ‘Contribution of the Transition Zone to the Strength of High Quality Silica Fume Concretes’, Proceedings, Materials Research Society, 114 (1987) 97–103.

Detwiler, R. J. and Mehta, K., ‘Chemical and physical effects of silica fume on the mechanical behavior of concrete’,ACI Materials Journal 86 (6) (1989) 609–614.

Goldman, A. and Bentur, A., ‘Bond effects in high silica-fume concretes’, (5) (1989) 440–447.

Huang, Cheng-Yi and Feldman, R. F., ‘Influence of silica fume on the microstructural development in cement mortars’,Cement and Concrete Research Journal 15 (1985) 285–294.

Toutanji, H. A. and El-Korchi, T., ‘The influence of silica fume on the compressive strength of cement paste and mortar’,25 (7) (1995) 1591–1602.

Hooton, R. D., ‘Influence of silica fume replacement of cement on physical properties and resistance to sulfate attack, freezing and thawing, and alkali-silica reactivity’,ACI Materials Journal 90 (2) (1993) 143–151.

Khedr, S. A. and Abou-Zeid, M. N., ‘Characteristics of silica fume concrete’,ASCE Materials Journal 6 (3) (1994) 357–375.

John R. and Shah, S. P., ‘Fracture mechanics analysis of high-strength concrete’,1 (4) (1989) 185–197.

Toutanji, H. A., ‘The Development of a Cementitious Composites Axial Tensile Technique and Its Application to Carbon Fiber Reinforced Cementitious Composites’, Ph.D. Thesis, Worcester Polytechnic Institute, Worcester, MA, 1992.

Toutanji, H. A. and El-Korchi, T., ‘Uniaxial tensile strength of cementitious composites’,ASTM Journal of Testing and Evaluation, JTEVA 22 (3) (1994) 226–232.

Christ, B. W. and Swanson, S. R., ‘Alignment problems in the tensile test’,ASTM Journal of Testing and Evaluation, JTEVA 4 (6) (1976) 405–417.

Baratta, F. I. and Driscoll, G. W., ‘A New Axial Tension Tester for Brittle Materials’ Army Materials and Mechanics Research Center, AMMRC TR 69-02, Watertown, MA, 1968.

Driscoll, G. W. and Baratta, F. I., ‘Modification to an Axial Tension Tester for Brittle Materials’,, Watertown, MA, 1971.

El-Korchi, T., Toutanji, H. A., Katz, R. N.,et al., ‘Tensile testing of fiber reinforced cementitious composites’,Proceedings of the Materials Research Society 211 (1991) 221–228.

ASEA CERAMA AB, ‘Introduction and Operation Manual for ASCERA Hydraulic Tensile Testing’, Robertsfors, Sweden, 1988.

Lucas, H. P., ‘Direct Tensile Testing of Brittle Materials’, Masters Thesis, Worcester Polytechnic Institute, Worcester, MA, 1991.

Hermansson, L., Adlerborn, J. and Burstrom, M., ‘Tensile Testing of Ceramic Materials-A New Approach’ High Tech. Ceramics, Edited by P. Vincenzini, Elssevier Science Publishers B. V., Amsterdam (1987) 1161–1168.

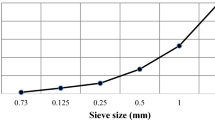

ASTM C33, ‘Standard Test Method for Grading Requirements of Aggregate’, Annual Book of ASTM Standards, Vol. 04.02, Concrete and Aggregate, 1988.

Feldman, R. F. and Cheng, Yi. H., ‘Properties of Portland cement silica fume pastes: Porosity and surface properties’,Journal of Cement and Concrete Research 15 (1985) 765–774.

de Larrard, F. and Roy, R. L., ‘The Influence of Mix Composition on Mechanical Properties of High Performance Silica Fume Concrete’ 4th International Conference on Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete, Istanbul, May 1992, 23 pp.

de Larrard, F., ‘Creep and Shrinkage of High Strength Field Concrete’, 2nd International Conference on Utilization of High Strength Concrete, ACI SP 121-28, May 1990, 577–598.

Amnon, K. and Bentur, A., ‘Effect of matrix composition on the aging of CFRC’,Journal of Cement and Concrete Composites 17 (2) (1995) 87–97.

Maher, A. and Darwin, D., ‘Microscopic Finite Element Model of Concrete’, Proceedings, First International Conference on Mathematical Modeling, University of Missouri-Rolla, St. Louis, Vol. III, (1977) 1705–1714.

ACI Committee 226, ‘Silica fume in concrete’,ACI Materials Journal 84 (2), 158–166.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Toutanji, H.A., Liu, L. & El-Korchi, T. The role of silica fume in the direct tensile strength of cement-based materials. Mat. Struct. 32, 203–209 (1999). https://doi.org/10.1007/BF02481516

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02481516