Abstract

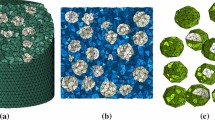

An experimental investigation of interface fracture in high strength concrete is reported. An attempt has been made to study the influence of strength of mortar, type of aggregate and its roughness on interface fracture properties. The parameters include load-CMOD variations, tensile strength, and fracture energy of the interface. Stiffness, compliance and ductility factors of the composite specimens have been evaluated in Mode-I loading. The fracture energy increases as the roughness of the aggregate surface increases. The stiffness of the composite specimen increases as the roughness of the aggregate surface increases. The ductility factor (i.e. the fracture energy per unit of peak load) decreases as the surface area of the interface increases in sandwiched composite specimens in Mode-I failure, whereas it increases with the interface area in composite specimens with mortar cast against rough concrete aggregates. The interface exhibits brittle behavior with catastrophic failure indicating the application of LEFM to the interface.

Résumé

L'article présente une recherche expérimentale sur la rupture de l'interface du béton à haute résistance. Cet article tente d'étudier l'influence de la résistance du mortier, du type de granulat et de sa rugosité sur les propriétés de la rupture d'interface. Les paramètres incluent les variations charge-CMOD, la résistance à la traction, l'énergie de rupture de l'interface. Les facteurs de raideur, de conformité et de ductilité des échantillons en matériaux composites ont été évalués au moyen du type de chargement Mode I. L'énergie de rupture augmente à mesure que la rugosité de la surface du granulat augmente. La raideur du matériau composite augmente à mesure que la rugosité de la surface du granulat augmente. Le facteur de ductilité, à savoir l'énergie de rupture par unité de charge maximale, baisse lorsque la surface de l'interface augmente dans des échantillons composites moisés en rupture en Mode I, tandis qu'il augmente avec la zone d'interface des échantillons en matériaux composites avec le mortier projeté contre le béton à gros granulats. L'interface démontre un comportement fragile, témoin d'une rupture catastrophique indiquant l'application de LEFM à l'interface.

Similar content being viewed by others

Abbreviations

- a0 :

-

Notch depth in the specimen, mm

- Alig :

-

Total area of the ligament, mm2

- b:

-

Thickness of the specimen, mm

- C:

-

Compliance, mm/N

- CMOD:

-

Crack mouth opening displacement, mm

- CMODc :

-

Critical crack mouth opening displacement, mm

- CS:

-

Casting surface

- d:

-

Depth of the specimen, mm

- GF :

-

Fracture energy, J/m2 (J=N-m)

- Gi :

-

Interface fracture energy, J/m2

- ITZ:

-

Interfacial Transition Zone

- k:

-

Stiffness of the specimen, kN/m

- Mode-I:

-

Loading, which opens the crack

- P:

-

Ultimate load, kN

- WF :

-

Work of fracture, J (=N-m)

References

Cheng-yi, H. and Feldman, R.F., ‘Influence of silica fume on the micro-structural development in cement mortars’,Cement and Concrete Research 15 (1985) 285–294.

Feldman, R.F., ‘The effect of sand/cement ratio and silica fume on the microstructure of mortars’,Cement and Concrete Research 16 (1986) 31–39.

Zimbelmann, R., ‘A method for strengthening the bond between cement paste and aggregates’,Cement and Concrete Research 17 (1987) 651–660.

Larbi, J.A. and Bijen, J.M.J.M., ‘Orientation of calcium hydroxide at the Portland cement paste-aggregate interface in mortars in the presence of silica fume: A contribution’,Cement and Concrete Research 20 (1990) 461–470.

Cohen, M.D., Goldman, A. and Chen, W.F., ‘The role of silica fume in mortar: Transition zone versus bulk paste modification’,Cement and Concrete Research 24 (1994) 95–98.

Ping, X. and Beaudoin, J.J., ‘Modification of transition zone microstructure-silica fume coating of aggregate surfaces’,Cement and Concrete Research 22 (1992) 597–604.

Pye, G.B. and Beaudoin, J.J., ‘An energy approach to bond strength determinations in cement systems’,Cement and Concrete Research 22 (1992) 551–558.

Tschegg, E.K., Rotter, H.M., Roelfstra, P.E., Bourgund, U. and Jussel, P., ‘Fracture mechanical behavior of aggregatecement matrix interfaces’,Journal of Materials in Civil Engineering 7 (4) (1996) 199–203.

Zhang, M.H. and Gjørv, O.E., ‘Microstructure of the interfacial zone between lightweight aggregate and cement paste’, Cement and Concrete Research20 (1990) 610–618.

Saito, M. and Kawamura, M., ‘Resistance of the cement-aggregate interfacial zone to propagation of cracks’,Cement and Concrete Research 16 (1986) 653–661.

Alexander, M.G., Two experimental techniques for studying the effects of the interfacial zone between cement paste and rock’,Cement and Concrete Research 23 (1993), 567–575.

Wong, Y.L., Lam, L., Poon, C.S. and Zhou, F.P., ‘Properties of fly ash-modified cement mortar-aggregate interfaces’,Cement and Concrete Research 29 (1999) 1905–1913.

Vervurt, A.H.J.M., ‘Interface Fracture in Concrete’, Doctoral Thesis, Delft University of Technology, Netherlands, 1997.

Lee, K.M. and Buyukozturk, O., ‘Fracture toughness of mortar-aggregate interfaces in high-strength concrete’,ACI Structural Journal 92 (1995) 734–642.

Trende, U. and Buyukozturk, O., ‘Size effect and influence of aggregate roughness in interface fracture of concrete composites’,ACI Materials Journal 95(4) (1998) 331–338.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Rao, G.A., Raghu Prasad, B.K. Influence of type of aggregate and surface roughness on the interface fracture properties. Mat. Struct. 37, 328–334 (2004). https://doi.org/10.1007/BF02481679

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02481679