Abstract

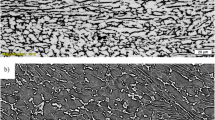

A ring-cutting test and an elastic theory were applied to evaluate the macroscopic residual stress in a thick-walled ring made of Al-SiC functionally graded material (FGM). The FGM ring specimens, with outer diameter 90 mm, radial thickness approximately 8.4 to 10 mm, and width 30 mm, were fabricated by the centrifugal casting method from an ingot of Duralcan F3D.20S of Al-20 vol pct SiC master composite. Because of a difference in centrifugal forces of SiC particles and of molten aluminum alloy, the rings had a graded composition of SiC particles in the radial direction. The volume fractions of SiC particles in each ring specimen varied in the range of 0 to 43 vol pct from the inner to the outer surface of the ring, depending on the applied mold spin speed. A ring diametral compression test was performed to validate an analytical formula based on the curved beam theory that can account for the graded properties of the material. Excellent agreement between the theory and the experiment was found. The residual stress was found to be generated by a cooling of Δt=140 K, which was from half the melting point corresponding stress-free condition to the ambient temperature. The hoop residual stresses in the FGM ring varied in the range of −50 to +35 MPa and from tension at the inner surface to compression at the outer surface because of the graded composition. With an increase in wall thickness and/or composition gradation, the residual stresses were found to increase.

Similar content being viewed by others

References

M. Koizumu and Y. Tada:Kinzoku, 1988, vol. 58, pp. 2–8.

Y. Fukui:JSME Int. J., 1991, Ser. III, vol. 34, pp. 144–48.

Y. Fukui, Y. Oya-Seimiya, and K. Nakanishi:JSME. J., 1991, Ser. A, vol. 57, pp. 1790–93.

G. Sacks:Z. Metallkd., 1927, vol. 19, pp. 352–57.

H.M. Ledbetter and M.W. Austin:Mater. Sci. Eng., 1987, vol. 89, pp. 53–61.

C.T. Kim, J.K. Lee, and M.R. Plichta:Metall. Trans. A, 1990, vol. 21A, pp. 673–82.

G.L. Povirk, M.G. Stout, M. Bourke, J.A. Goldstone, A.C. Lawson, A.C. Lawson, M. Lovato, S.R. Nutt, and A. Needleman:Acta Metall. Mater., 1992, vol. 40, pp. 2391–2412.

S. Timoshenko and J.M. Lessells:Applied Elasticity, Westinghouse Technical Night School Press, New York, NY, 1925.

S. Timoshenko:Strength of Materials, D. Van Nostrand Company Inc., New York, NY, 1955.

T. Ohta:Strength of Materials, Sankaido, Tokyo, Japan, 1966 (in Japanese).

W.A. Nash:Theory and Problems of Strength of Materials, McGraw-Hill Book Company, New York, NY, 1972, pp. 230–246.

K. Wakashima:Trans. Jpn. Soc. Comp. Mater., 1976, vol. 2, pp. 161–67.

Y. Fukui, H. Kinoshita, and K. Nakanishi:JSME Int. J., 1992, Ser. I, vol. 35, pp. 95–101.

Y. Fukui and N. Yamanaka:JSME Int. J., 1992, Ser. I, vol. 35, pp. 379–85.

Y. Fukui, N. Yamanaka, and K. Wakashima:JSME Int. J., 1993, Ser. A, vol. 36A, pp. 156–62.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Fukui, Y., Watanabe, Y. Analysis of thermal residual stress in a thick-walled ring of duralcan-base Al-SiC functionally graded material. Metall Mater Trans A 27, 4145–4151 (1996). https://doi.org/10.1007/BF02595662

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02595662