Abstract

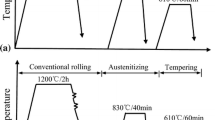

In commercial practice 5.5Ni steel is toughened for cryogenic service by a three-step heat treatment designated the “QLT” treatment. To determine why this treatment is necessary and successful, a series of two-step heat treatments was applied to 5.5Ni steel and the resulting microstructural states were characterized and compared with that obtained through the QLT treatment. It was concluded from this analysis that the QLT treatment lowers the ductile-brittle transition temperature by precipitating a dense distribution of thermally stable austenite along the boundaries of martensite laths, which interrupts the crystallographic alignment of laths within martensite packets and prevents cooperative trans-packet cleavage. Essentially, it reduces the mean free fracture path for cleavage. The multistep heat treatment is necessary because of the low nickel content; a single step heat treatment leads to an austenite precipitate which is either too lean in solute to be retained or too coarse in its distribution to be effective. The problem is avoided in the QLT treatment since the intercritical anneal (L) serves to create regions of high solute content along the prior martensite lath boundaries. The intercritical temper (T) then precipitates a dense distribution of high solute, stable austenite within these enriched regions.

Similar content being viewed by others

References

J.W. Morris, Jr., C.K. Syn, J.I. Kim, and B. Fultz:Proceedings of the International Conference on Martensitic Transformation, W. Owen, ed., M.I.T. Press, Cambridge, MA, 1979, p. 572.

S. Nagashima, T. Ooka, S. Sekino, H. Mimura, T. Fujishima, S. Yano, and Sakurai:Trans. ISIJ, 1971, vol. 11, p. 402.

S. Nagashima, T. Ooka, S. Sekino, H. Mimura, T. Fujishima, S. Yano, and H. Sakurai:Tetsu-to-Hagane, 1972, vol. 58, p. 128.

M. Niikura and J.W. Morris, Jr.:Metall. Trans. A, 1980, vol. 11A, p. 1531.

S.K. Hwang and J.W. Morris, Jr.:Metall. Trans. A, 1980, vol. 11A, p. 1197.

J.I. Kim and J.W. Morris, Jr.:Metall. Trans. A, 1981, vol. 12A, p. 1597.

R. L. Miller:Trans. ASM, 1964, vol. 57, p. 892.

B. Fultz: M. S. Thesis, University of California, Berkeley, CA, 1978.

ASTM Standard E 23,Annual Book of ASTM Standards, 1979, p. 237.

J.I. Kim and J.W. Morris, Jr.:Metall. Trans. A, 1980, vol. 11A, p. 1401.

B. Fultz: Dept. Materials Science and Mineral Engineering, Univ. of California, Berkeley, CA, unpublished research (presented at AIME Annual Meeting, Las Vegas, NV, February 1980).

M. Niikura, T. Yamada, and J. Tanaka: Central Research Laboratories, Nippon Kokan K. K., Kawasaki, Japan, private communication, 1980.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, J.I., Syn, C.K. & Morris, J.W. Microstructural sources of toughness in QLT-Treated 5.5Ni cryogenic steel. Metall Trans A 14, 93–103 (1983). https://doi.org/10.1007/BF02643742

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02643742