Abstract

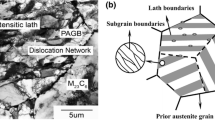

The influence of a modified heat treatment (MHT) and the standard heat treatment (SHT) on the damage tolerance of alloy 718 turbine disk material has been studied over a range of temperatures— from room temperature to 650 °. The influence of these heat treatments on creep, low-cycle fatigue (LCF), notch sensitivity, cyclic stability, and fatigue crack growth rate (FCGR) properties has been studied. The microstructure developed through the MHT sequence is shown to be damage tolerant over the temperature range studied. Shot peening leads to a marked improvement in the LCF crack initiation life of the MHT material relative to the SHT material at 650 °. Serrated grain boundaries formed through controlled precipitation of grain-boundary 5 phase are beneficial to elevated- temperature FCGRs. The S-phase precipitates formed at an angle to the grain boundaries do not make the material notch sensitive.

Similar content being viewed by others

References

A.K. Koul, P. Au, N. Bellinger, R. Thamburaj, W. Wallace, and J.-P. Immarigeon, Development of a Damage Tolerant Microstructure for Inconel 718 Turbine Disc Material,Superalloys 1988, D.N. Duhl, G. Maurer, S. Antolovich, C. Lund, and S. Reichman, Ed., TMS, 1988, p 3-12

D.D. Krueger, R.D. Kissinger, and R.G. Menzies, Development and Introduction of a Damage Tolerant High Temperature Nickel-Base Disk Alloy, René88DT,Superalloys 1992, S.D. An- tolovich, R.W. Stusrud, R.A. MacKay, D.L. Anton, T. Khan, R.D. Kissinger, and D.L. Klarstrom, Ed., TMS, 1992, p 277-286

J.Y. Guedou, J.C. Lautridou, and Y. Honnorat, N18, PM Superal- loy for Disks: Development and Applications,Superalloys 1992, S.D. Antolovich, R.W. Stusrud, R.A. MacKay, D.L.Anton, T. Khan, R.D. Kissinger, and D.L. Klarstrom, Ed., TMS, 1992, p 267-276

S.D. Antolovich, The Effect of Metallurgical Instabilities on the Behaviour of IN718,Superalloy 718—Metallurgy and Applica- tions, E.A. Loria, Ed., TMS, 1989, p 647-653

H. Bande, Y. Xiao, P. Au, A.K. Koul, and W. Wallace, Low Cycle Fatigue Fracture Behaviour of Conventional and Damage Toler- ant Microstructures of Inconel 718 at 650 °,Surface Engineer- ing, S.A. Meguid, Ed., Elsevier Applied Science, 1990, p 238- 251

M. Chang, A. Au, T. Terada, and A.K. Koul, Damage Tolerance of Alloy 718 Turbine Disc Material,Superalloys 1992, S.D. An- tolovich, R.W. Stusrud, R.A. MacKay, D.L. Anton, T. Khan, R.D. Kissinger, and D.L. Klarstrom, Ed., TMS, 1992, p 447-456

G. Sjoberg, N.-G. Ingesten, and R.G. Carlson, Grain Boundary δ- phase Morphologies, Carbides and Notch Rupture Sensitivity of Cast Alloy 718,Superalloys 718, 625 and Various Derivatives, E.A. Loria, Ed., TMS, 1991, p 603-621

J.M. Poole, K.R. Stultz, and J.M. Manning, The Effect of Ingot Homogenization Practice on the Structure and Properties of Wrought Alloy 718,Superalloy 718—Metallurgy and Applica- tions, E.A. Loria, Ed., TMS, 1989, p 219-228

J.P. Pédron and A. Pineau, The Effect of Microstructure and En- vironment on the Crack Growth Behaviour of Inconel 718 Alloy at 650 ° under Fatigue, Creep and Combined Loading,Mater. Sci. Eng., Vol 56, 1982, p 143–156

L.A. James and W.J. Mills, Effect of Heat-Treatment and Heat- to-Heat Variations in the Fatigue Crack Growth Response of Al- loy 718,Eng. Fract. Mech., Vol 22(No. 5). 1985, p 797–817

J.Z. Xie, Low Cycle Fatigue and Fatigue Crack Growth Behav- iours of Alloy 718,Superalloys 718, 625 and Various Deriva- tives, E.A. Loria, Ed., TMS, 1991, p 491-500

M. Gell and G.R. Leverant, Mechanisms of High Temperature Fatigue,Fatigue at Elevated Temperatures, STP 520, A.E. Car- den, A.J. McEvily, and C.H. Wells, Ed., ASTM, 1973, p 37-67

J. Benson, R. Hunziker, and C. Williams, Rejuvenation of Wrought IN-718 Diffuser Cases,Superalloys 1992, S.D. An- tolovich, R.W. Stusrud, R.A. MacKay, D.L. Anton, T. Khan, R.D. Kissinger, and D.L. Klarstrom, Ed., TMS, 1992, p 877-883

R.G. Andrews, A.K. Koul, and P. Au, Fatigue Crack Initiation in Alloy 718 at 650 °,Superalloys 718, 625 and Various Deriva- tives, E.A. Loria, Ed., TMS, 1991 ,p943-954

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chang, M., Koul, A.K., Au, P. et al. Damage tolerance of wrought alloy 718 Ni- Fe-base superalloy. JMEP 3, 356–366 (1994). https://doi.org/10.1007/BF02645332

Issue Date:

DOI: https://doi.org/10.1007/BF02645332