Abstract

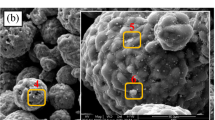

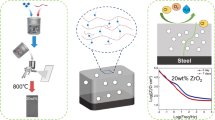

This paper describes the corrosion fatigue behavior and fracture mechanisms of a steel with different sprayed coatings. Rotating bending fatigue tests were conducted in 3% NaCl solution using specimens of a medium carbon steel with sprayed coatings of a ceramic (Cr2O3), a cermet (WC-12%Co) and two metals (Ni-11 % P and Al-2% Zn). The corrosion fatigue process was basically the same for ceramic, cermet, and Ni-11 % P sprayed specimens. That is, the corrosive media could be supplied from the specimen surface to the substrate through cracks initiated during fatigue cycling and/or pores in the coatings, and thus corrosion pits were generated followed by subsequent crack initiation and growth in the substrate. The corrosion fatigue strength of ceramic sprayed specimens was slightly improved compared to that of the substrate steel because the under-coating (Ni-5%A1) could impede the penetration of the corrosive media although the ceramic coating had a poor resistance to cracking under cyclic loading. Cermet sprayed specimens also exhibited improved corrosion fatigue strength because of the high resistance to cracking and the low volume fraction of pores of the coating. In Ni-11 % Psprayed specimens, cracks were initiated in the coating even at low stress levels; thus the corrosion fatigue strength was the same as that of the substrate. Anodic dissolution took place in Al-2 % Zn coating because the coating was electrochemically poor, and thus the substrate was cathodically protected. Therefore, the corrosion fatigue strength of Al-2 % Zn sprayed specimens was enhanced to as high as the fatigue strength of the substrate in room air. Based on the experimental results, a dual-layer coating consisting of WC-12%Co and Al-2%Zn was fatigue tested. The coating was effective at low stress levels and exhibited long life under conditions where corrosion fatigue strength was critical.

Similar content being viewed by others

References

S.L. Evans and P.J. Gregson, The Effect of a Plasma-Sprayed Hy- droxyapatite Coating on the Fatigue Properties of Ti-6A1-4V,Mater. Lett.. Vol 16 (No. 5), 1993, p 270–274

H. Nakahira, Y. Harada, K. Tani, R. Ebara, and Y. Yamada, Improve- ment of Corrosion Fatigue Strength of High Strength Steel by Thermal- Sprayed (WC-Cr-Ni) Cermet Coating,J. Soc. Mater. Sci., Jpn., Vol 43 (No. 490), 1994, p 888–894 (in Japanese)

M. Sugano, H. Masaki, J. Kishimoto, Y. Nasu, and T. Satake, A Micro- structural Study of Fatigue Damage in Stainless Steel Coated with Plasma-Sprayed Alumina,Thermal Spraying: Current Status and Future Trends, A. Ohmori, Ed., High Temperature Society of Japan, 1995, p 145–150

T. Shiraishi, H. Ogiyama, and H. Tsukuda, Effect of Thermal Sprayed Ceramic Coatings on Fatigue Behavior of Metals,Thermal Spraying: Current Status and Future Trends, A. Ohmori, Ed., High Temperature Society of Japan, 1995, p 845-850

The Japan Society of Precision Engineering, Plasma Spraying,Hyomenkaishitsugijutsu, The Nikkan Kogyo Shimbun, 1988, p 182 (in Japanese)

J.U. Hwang, T. Ogawa, and K. Tokaji, Fatigue Strength and Fracture Mechanisms of Ceramic-Sprayed Steel in Air and a Corrosive Environ- ment,Fatigue Fract. Eng. Mater. Struct., Vol 17 (No. 7), 1994, p 839- 848

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tokaji, K., Ogawa, T., Hwang, J.U. et al. Corrosion fatigue behavior of a steel with sprayed coatings. JTST 5, 269–276 (1996). https://doi.org/10.1007/BF02645877

Issue Date:

DOI: https://doi.org/10.1007/BF02645877