Abstract

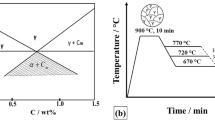

The effect of composition on the dynamic recrystallization behavior of plain carbon steels has been examined in the temperature range 850 to 1300 °C and the strain-rate range 6 × 10-6 to 2 × 10-2 s-1. With increasing solute content, the onset of dynamic recrystallization is delayed and the rate of recrystallization is decreased. At 1000 °C the elements can be ranked in order of increasing effectiveness as C, Ni, Mn, Si, P. At higher temperatures the effect of composition is complicated by its effect on grain coarsening, which itself postpones the onset and slows the rate of recrystallization. Similarly, for steels in which precipitation may occur, a fine-grain structure can promote the earlier onset and faster rate of recrystallization. Thus, out of an examination of the effect of composition comes an appreciation of the influence of initial grain size. Another factor which can complicate any explanation of the compositional dependence of dynamic recrystallization is grain-boundary segregation, which is probably responsible for the strong retarding influence of phosphorus.

Similar content being viewed by others

References

See, for example, several contributions toProc. Intern. Conf. Thermomechanical Processing of Microalloyed Austenite, A.J. DeArdo, G. A. Ratz, and P. J. Wray, eds., TMS-AIME, Warrendale, PA, 1982.

P.J. Wray:Metall. Trans. A, 1975, vol. 6A, pp. 1197–203.

P.J. Wray:The Hot Deformation of Austenite, J.B. Bailance, ed., TMS-AIME, New York, NY, 1977, pp. 86–112.

P.J. Wray:Metall. Trans. A, 1982, vol. 13A, pp. 125–34.

T. Sakai, M. G. Akben, and J. J. Jonas:Proc. Intern. Conf. Thermomechanical Processing of Microalloyed Austenite, A.J. DeArdo, G. A. Ratz, and P. J. Wray, eds., TMS-AIME, Warrendale, PA, 1982, pp. 237–52.

M.G. Burke: U.S. Steel Research Laboratory, private communication, Monroeville, PA, July 1982.

I. Kozasu, C. Ouchi, T. Sampei, and T. Okita:Microalloying '75, M. Korchynsky, ed., Union Carbide Corporation, New York, NY, 1977, pp. 120–35.

T. Maki, K. Akasaka, K. Okuna, and I. Tamura:Trans. Iron Steel Inst. Jpn., 1982, vol. 22, pp. 253–61.

C. Ouchi and T. Okita:Trans. Iron Steel Inst. Jpn., 1982, vol. 22, pp. 543–51.

P.J. Wray:Scripta Met., 1981, vol. 15, pp. 45–50.

J. P. Bailon and F. Weinberg:Canad. Metall. Quarter., 1980, vol. 19, pp. 251–57.

P. Héritier, A. Fourdeux, and A. Kobylanski:Scripla Met., 1981, vol. 15, pp. 753–55.

H.W. Mead and C.E. Birchenall:Trans. AIME, 1956, vol. 206, pp. 1336–39.

S. K. Roy, H. J. Grabke, and W. Wepner:Arch. Eisenhuttenw., 1980, vol. 81, pp. 91–96.

W. Charnock and J. Nutting:Met. Sci. J., 1967, vol. I, pp. 123–27.

T. Chandra, M.G. Akben, and J.J. Jonas:Proc. Sixth Intern. Conf. Strength of Metals and Alloys, R. C. Gifkins, ed., Melbourne, 1982, vol. 1, pp. 499–504.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wray, P.J. Effect of composition and initial grain size on the dynamic recrystallization of austenite in plain carbon steels. Metall Trans A 15, 2009–2019 (1984). https://doi.org/10.1007/BF02646835

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02646835