Abstract

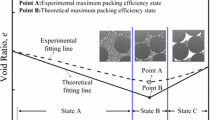

Bimodal mixtures improve the green density of powder systems and are used in processes such as slip casting and powder injection molding. The packing density can be predicted with reasonable accuracy, but there is great uncertainty in the sintered density of a bimodal mixture. The large/small composition effect on packing density and sintered density is treated using the specific volume. For a given composition, the packing density is accurately predicted when four parameters are known: particle size ratio, packing density of the small powder, packing density of the large powder, and mixture homogeneity. Prediction of the sintered density is possible from knowledge of the densification of the large and small powders and mixture homogeneity. The model is applied to bimodal mixtures of molybdenum, stainless steel, iron, and alumina. Certain criteria must be satisfied by the constituent powders for a bimodal mixture to exhibit the highest sintered density. In many situations, the highest sintered density occurs at the 100 pct small powder composition.

Similar content being viewed by others

References

C.C. Furnas:Ind. Eng. Chem., 1931, vol. 23, pp. 1052–58.

R.M. German:Particle Packing Characteristics, Metal Powder Industries Federation, Princeton, NJ, 1989, pp. 135–80.

R.L. Coble:J. Am. Ceram. Soc, 1973, vol. 56, pp. 461–66.

F.F. Lange:J. Am. Ceram. Soc, 1984, vol. 67, pp. 83–89.

G.Y. Onoda: inCeramic Microstructures ’76, R.M. Fulrath and J.A. Pask, eds., Westview Press, Boulder, CO, 1977, pp. 163–81.

A.E.R. Westman and H.R. Hugill:J. Am. Ceram. Soc, 1930, vol. 13, pp. 767–79.

K. Ridgway and K.J. Tarbuck:Chem. Process Eng., 1968, vol. 49, pp. 103–05.

N. Epstein and M.J. Young:Nature, 1962, vol. 196, pp. 885–86.

S. Yerazunis, S.W. Cornell, and B. Wintner:Nature, 1965, vol. 207, pp. 835–37.

R.K. McGeary:J. Am. Ceram. Soc, 1961, vol. 44, pp. 513–22.

J. Ayer and F.E. Soppet:J. Am. Ceram. Soc, 1965, vol. 48, pp. 180–83.

D.I. Lee:J. Paint Technol., 1970, vol. 42, pp. 579–87.

H.J. Fraser:J. Geol., 1935, vol. 43, pp. 910–1010.

J.V. Milewski: inHandbook of Reinforcements for Plastics, J.V. Milewski and H.S. Katz, eds., Van Nostrand Reinhold, New York, NY, 1987, pp. 14–33.

Y.V. Maksimov:Colloid J. USSR, 1986, vol. 48, pp. 693–94.

J. Eastwood, E.J.P. Matzen, M.J. Young, and N. Epstein:Br. Chem. Eng., 1969, vol. 14, pp. 1542–45.

A.B. Yu and N. Standish:Powder Technol., 1987, vol. 52, pp. 233–41.

W. Gray:The Packing of Solid Particles, Chapman and Hall, London, 1968.

G.Y. Onoda and G.L. Messing: inProcessing of Crystalline Ce- ramics, H. Palmour, R.F. Davis, and T.M. Hare, eds., Plenum Press, New York, NY, 1978, pp. 99–111.

G.L. Messing and G.Y. Onoda:J. Am. Ceram. Soc, 1978, vol. 61, pp. 1–5.

S.T. Lin: Ph. D. Thesis, Rensselaer Polytechnic Institute, Troy, NY, 1991.

M.J. O’Hara and I.B. Cutler:Proc Br. Ceram. Soc, 1969, no. 12, pp. 145–54.

J.P. Smith and G.L. Messing:J. Am. Ceram. Soc, 1984, vol. 67, pp. 238–42.

R. Raj and R.K. Bordia:Acta Metall., 1984, vol. 32, pp. 1003–19.

C.H. Hsueh:J. Am. Ceram. Soc, 1988, vol. 71, pp. C314-C315.

F.W. Dynys and J.W. Halloran:J. Am. Ceram. Soc, 1984, vol. 67, pp. 596–601.

C.H. Hsueh, A.G. Evans, R.M. Cannon, and R.J. Brook:Acta Metall., 1986, vol. 34, pp. 927–36.

B.R. Patterson, V.D. Parkhe, and J. A. Griffin: inSintering ’85, G.C. Kuczynski, D.P. Uskokovic, H. Palmour, and M.M. Ristic, eds., Plenum Press, New York, NY, 1987, pp. 43–51.

G.W. Scherer:J. Am. Ceram. Soc, 1987, vol. 70, pp. 766–74.

C.H. Hsueh:J. Am. Ceram. Soc, 1988, vol. 71, pp. C442-C444.

C.H. Hsueh, A.G. Evans, and R.M. McMeeking:J. Am. Ceram. Soc, 1986, vol. 69, pp. C64-C66.

B. Kellett and F.F. Lange:J. Am. Ceram. Soc, 1984, vol. 67, pp. 369–71.

L.C. DeJonghe, M.N. Rahaman, and C.H. Hsueh:Acta Metall., 1986, vol. 34, pp. 1467–71.

M.N. Rahaman and L.C. DeJonghe:J. Am. Ceram. Soc, 1987, vol. 70, pp. C348-C351.

F.F. Lange and M. Metcalf:J. Am. Ceram. Soc, 1983, vol. 66, pp. 398–406.

F.F. Lange, B.I. Davis, and I.A. Aksay:J. Am. Ceram. Soc, 1983, vol. 66, pp. 407–08.

R.M. German:Powder Metallurgy Science, Metal Powder Industries Federation, Princeton, NJ, 1984, p. 159.

A.R. Poster, C.T. Waldo, and H.H. Hausner:Prog. Powder Metall., 1960, vol. 16, pp. 56–70.

M. Bulger: M.S. Thesis, Rensselaer Polytechnic Institute, Troy, NY, 1990.

J. Takekawa:J. Jpn Soc. Powder Metall., 1988, vol. 35, pp. 641–45.

R.M. German:Powder Injection Molding, Metal Powder Industries Federation, Princeton, NJ, 1990.

P.F. Murley and R.M. German: inAdvances in Powder Metal- lurgy, T.G. Gasbarre and W.F. Jandeska, eds., Metal Powder Industries Federation, Princeton, NJ, 1989, vol. 3, pp. 103–20.

R.T. Fox, D. Lee, M.K. Bulger, and R.M. German: inAdvances in Powder Metallurgy, E.R. Andreotti and P.J. McGeehan, eds., Metal Powder Industries Federation, Princeton, NJ, 1990, vol. 3, pp. 359–73.

H.E. Amaya and J. St. Pierre: inModern Developments in Pow- der Metallurgy, P.U. Gummeson and D.A. Gustafson, eds., Metal Powder Industries Federation, Princeton, NJ, 1988, vol. 18, pp. 323–31.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

German, R.M. Prediction of sintered density for bimodal powder mixtures. Metall Trans A 23, 1455–1465 (1992). https://doi.org/10.1007/BF02647329

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02647329