Abstract

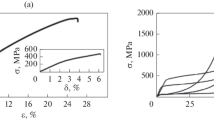

When uranium-niobium alloys containing between 13.9 and 17.9 at. pct Nb are quenched to room temperature from the BCC (γ) phase at elevated temperatures, diffusion-controlled precipitation of the equilibrium phases is prevented and martensitic transformations to transition phases occur instead. Dilatometry was used to detect transformation temperatures and with the help of X-ray diffraction analysis, a metastable phase diagram was established. At room temperature after quenching, alloys containing < 15.2 at. pct Nb were monoclinic (α″) and those with < 16.6 at. pct Nb were tetragonal (γ°). The deformation behavior and shape memory effects (SME) accompanying the reverse martensitic phase transformations in polycristalline specimens were surveyed and characterized phenomelogically. From uniaxial tensile tests at room temperature, macroscopic stress-strain parameters, associated with the reversible deformation modes in the α″ and γ° martensites, were defined and their composition and structural state dependencies delineated. A diffuse maximum manifested in the stress-strain diagrams was identified with the reversible strain limit, which varied inversely and continuously with composition. A concentration-independent value of 693 MPa was found for the plastic yield strength of the alloys. All the alloys exhibited heat-activated shape recovery but the degree depended on structural state and composition. The α″ alloys showed a much larger effect than γ° alloys. Shape recovery occurred in two stages in all alloys. The first stage of recovery accompanied martensite reversion but final reversion to the equilibrium y phase was not accomplished until much higher temperatures were reached. Rapid, low temperature aging reactions were thought to affect the finish of shape recovery and delay it to higher temperatures.

Similar content being viewed by others

References

P. Duwez:J. of Nucl. Mat., 1953, vol. 24, p. 152.

B. A. Rogers, D. F. Atkins, E. J. Manthos, and M. E. Kilpatrick: TRANS TMS-AIME, 1958, vol. 212, p. 387.

M. Anagnostides, M. Columbie, and H. Monti:J. of Nucl. Mat., 1964, vol. 11, p. 67.

K. Tangri and D. K. Chandhuri:J. of Nucl. Mat., 1965, vol. 15, p. 278.

R. J. Jackson: The Dow Chemical Co., Rocky Flats Div., Golden, Colo., Rept. No. RFP-1535, 1970.

A. Goldberg and T. B. Massalski: “Phase Transformations in the Actinides,”Plutonium 1970 and Other Actinides, Nuclear Metallurgy, vol. 17, Part II, ed., W. N. Miner, TMS-AIME, New York, 1970, p. 875.

J. J. Rechtien and R. D. Nelson:Met. Trans., 1973, vol. 4, p. 2755.

D. Stewart and G. I. Williams:J. of Nucl. Mat., 1966, vol. 20, p. 262.

B. W. Howlett:J. of Nucl. Mat., 1970, vol. 35, p. 278.

K. Tangri and G. I. Williams:J. of Nucl. Mat., 1961, vol. 4, p. 226.

D. Blake and R. F. Hehemann:Physical Metallurgy of Uranium Alloys, ed. J. Burkeet. al., Brookhill Publishing, Chestnut Hill, Mass., 1976, p. 189.

R. A. Vandermeer:Acta Met., 1980, vol. 28, p. 383.

R. J. Jackson and W. L. Johns: The Dow Chemical Co., Rocky Flats Div., Golden, Colo., Rept. No. RFP-996, 1970.

R. A. Vandermeer, J. C. Ogle, and W. B. Snyder, Jr.:Scripta Met., 1978, vol. 12, p. 243.

J. L. Cadden, N. C. Jessen, Jr., and P.S. Lewis, Jr.:Physical Metallurgy of Uranium Alloys, ed. J. Burkeet. al., Brookhill Publishing, Chestnut Hill, Mass., 1976, p. 3.

A. S. Sastri and M. J. Marcinkowski: Trans. TMS-AIME, 1968, vol. 242, p. 2393.

R. V. Krishnan and L. C. Brown:Met. Trans., 1973, vol. 4, p. 423.

T. A. Schroeder, I. Cornelis, and C. M. Wayman:Met. Trans, A., 1976, vol. 7A, p. 535.

L. Delaey, R. V. Krishnan, H. Tas and H. Warlimont:J. Mater. Sci., 1974, vol. 9, p. 1521.

W. S. Owen:Shape Memory Effects in Alloys, ed. J. Perkins, Plenum Press, New York, 1975, p. 305.

J. Perkins, G. R. Edwards, C. R. Such, J. M. Johnson, and R. R. Allen:Shape Memory Effects in Alloys, ed. J. Perkins, Plenum Press, New York, 1975, p. 273.

D. S. Lieberman, M. A. Schmerling, and R. W,. Karz:Shape Memory Effects in Alloys, ed. J. Perkins, Plenum Press, New York, 1975, p. 203.

J. D. Eisenwasser and L. C. Brown:Met. Trans., 1972, vol. 3, p. 1359.

R. J. Jackson and D. V. Miley: Trans ASM, 1968, vol. 61, p. 336.

H. A. Mohamed and J. Washburn:J. Mater. Sci., 1977, vol. 12, p. 469.

A. G. Rozner and R. J. Wasilewski:J. Inst. Met., 1966, vol. 94, p. 169.

N. Nakanishi:Shape Memory Effects in Alloys, ed. J. Perkings, Plenum Press, New York, 1975, p. 147.

Author information

Authors and Affiliations

Additional information

Formerly with Metals and Ceramics Division, Oak Ridge National Laboratory

Rights and permissions

About this article

Cite this article

Vandermeer, R.A., Ogle, J.C. & Northcutt, W.G. A phenomenological study of the shape memory effect in polycrystalline uranium-niobium alloys. Metall Trans A 12, 733–741 (1981). https://doi.org/10.1007/BF02648337

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02648337