Abstract

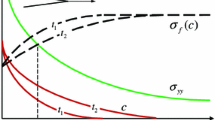

Hydrogen embrittlement is shown to occur very easily in notched-round bars under opening modeI (tension) but not under antiplane shear modeIII (torsion). The stress tensor invariants under modeI,II, andIII loadings and how these affect interstitial diffusion are discussed. It is suggested that long range diffusion of hydrogen down orthogonal trajectories to the vicinity of the crack tip, which can occur under modeI but not modeIII, is a key part of any hydrogen embrittlement mechanism. This premise was evaluated with AISI 4340 steel heat treated to ultrahigh strength levels. It was found that an initial modeI stress intensity level of 17,000 psi-in.1/2 produced failure in several minutes. ModeIII stress intensity levels three times this produced no crack initiation in 300 min. Further analysis of the time-dependent hydrogen concentrating effect utilized a stress wave emission technique. This produced plausible critical hydrogen concentrations even though the present elastic analysis is a first order approximation of the stress field.

Similar content being viewed by others

References

D. P. Williams and H. G. Nelson:Met. Trans., 1971, vol. 2, p. 1987.

C. F. Barth and E. A. Steigerwald:Met. Trans., 1971, vol. 2, p. 1988.

R. A. Oriani:Fundamental Aspects of Stress Corrosion Cracking, p. 32, Na-tional Association of Corrosion Engineers,Houston, 1969.

H. W. Liu:J. Basic Eng., ASME, 1970, vol. 92, p. 633.

D. McLean:Grain Boundaries in Metals, p. 118, Oxford at the Clarendon Press, 1957.

C. F. Barth and E. A. Steigerwald:Met. Trans., 1970, vol. 1, p. 3451.

C. E. Hartbower, W. W. Gerberich, and P. P. Crimmins:Welding J. Res. Supp., 1968, vol. 47, no. l,p. 1s.

A. J. Baker, F. J. Lauta, and R. P. Wei:Amer. Soc. Test. Mater. Special Tech. Publ. 370, 1965, p. 3.

W. F. Brown and J. E. Srawley:Amer. Soc. Test. Mater. Special Tech. Publ. 410, 1966.

W. K. Wilson, W. G. Clark, Jr., and E. T.Wessel: Fracture Mechanics Technology for Combined Loading and Low-To-Intermediate Strength Metals, Westinghouse Research Lab., Contract DAAE 07-67-C-4021, November 1968.

J. C. M. Li, R. A. Oriani, and L. S. Darken:Z. Physik. Chem., 1966, vol. 49, p. 271.

R. A. Oriani:Fundamental Aspects of Stress Corrosion Cracking, p. 49, Na-tional Assoc. of Corrosion Engineers, Houston, 1969; see also W. W. Gerberich and C. E. Hartbower, p. 426 ;M. Smialowski, p. 463.

P. C. Paris and G. C. Sih:Amer. Soc. Test. Mater. Special Tech. Publ. 381, 1965, p. 30.

Author information

Authors and Affiliations

Additional information

Formerly Graduate Student and Lecturer, respectively, University of California, Berkeley

Rights and permissions

About this article

Cite this article

John, C.S., Gerberich, W.W. The effect of loading mode on hydrogen embrittlement. Metall Trans 4, 589–594 (1973). https://doi.org/10.1007/BF02648714

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02648714