Abstract

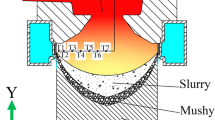

A water-cooling centrifugal casting method was applied to cast the 7075 Al alloy to generate a much finer cast structure than that produced by conventional ingot casting methods. The effects of casting parameters, i.e., rotation speed, pouring temperature, water flow, and grain refiner, on casting structure were systematically studied so that the optimum casting condition and the solidification mechanism could be established. The typical cast structure along the thickness direction of a cast ring could be divided into four equiaxed zones, including the chill zone which is in contact with the mold wall. All zones have their characteristic grain size, morphology, and relative thickness, which are all dependent on the casting condition. The optimum casting condition yielding the finest structure available was found to be 3000 rpm, 650 °C, and sufficient water cooling. A uniform portion occupying 90 pct of the whole thickness and having a grain size of 17 μm could be achieved under such a casting condition. When a grain refiner was added, the whole ring became further concentrated with grains of fine structure. A mechanism concerning the overall effects of rapid solidification, turbulent flow, and centrifugal force has been proposed for the present casting method and might explain the zone-structure formation and the effects of the casting parameters on microstructural features.

Similar content being viewed by others

References

N. Church, P. Wieser, and J.F. Wallace:Mod. Castings, 1966, vol. 49, p. 129.

Ultrafine-Grain Metals, J.J. Burke and V. Weiss, eds., Syracuse University Press, New York, NY, 1970.

M.C. Flemings:Solidification Processing, McGraw-Hill, New York, NY, 1974, pp. 341–44.

G.S. Cole and G.F. Boiling: inUltrafine-Grain Metals, J.J. Burke and V. Weiss, eds., Syracuse University Press, New York, NY, 1970, pp. 31–69.

G.S. Cole, K.W. Casey, and G.F. Boiling:Metall. Trans., 1970, vol. 1, pp. 1413–16.

L. Backerud:Light Met. Age, 1983, vol. 10, p. 6.

W.C. Johnston, G.R. Kotler, and W.A. Tiller:Trans. TMS-AIME, 1963, vol. 227, pp. 890–96.

S. O’Hara and W.A. Tiller:Trans. TMS-AIME, 1967, vol. 239, pp. 497–501.

G.S. Cole and G.F. Boiling:Trans. TMS-AIME, 1967, vol. 239, pp. 1824–35.

J.D. Hunt and K.A. Jackson:J. Appl. Phys., 1966, vol. 37, pp. 254–57.

J.R. Picken:J. Mater. Sci., 1981, vol. 16, pp. 1437–57.

W.E. Quist and R.E. Lewis:Rapidly Solidified Powder Aluminum Alloys, ASTM, Philadelphia, PA, 1984, pp. 7–30.

R.E. Maringer and C.E. Mobley:Rapid Solidification Process Principle and Technologies, Proc. Int. Conf. on Rapid Solidification Processing, Claitor’s Publishing Division, Baton Rouge, LA, 1977, pp. 208–21.

R.M. German:Powder Metallurgy Science, Metal Powder Industries Federation, Princeton, NJ, 1984.

P.K. Domalavage, N.J. Grant, and Y. Gefen:Metall. Trans. A, 1983, vol. 14A, pp. 1599–1606.

ASM Metals Handbook, 9th ed., 1979, vol. 2, pp. 63–139.

N.J. Grant:Rapid Solidification Processing, Claitor’s Publishing Division, Baton Rouge, LA, 1977, pp. 230–45.

ASM Metals Handbook, 9th ed. 1988, vol. 15, pp. 297–307.

F.F.Y. Wang:Ceramic Fabrication Processes, Academic Press, New York, NY, 1976, pp. 42–47.

J.E. Hatch:Aluminum Properties and Physical Metallurgy, ASM INTERNATIONAL, Metals Park, OH, 1984, pp. 1–19.

M.C. Flemings:Solidification Processing, McGraw-Hill, New York, NY, 1974, pp. 154–57.

Author information

Authors and Affiliations

Additional information

SHANG-HAW JONG is in the military service, Hsinchu, Taiwan, Republic of China

Rights and permissions

About this article

Cite this article

Yeh, JW., Jong, SH. The cast structure of a 7075 alloy produced by a water-cooling centrifugal casting method. Metall Mater Trans A 25, 643–650 (1994). https://doi.org/10.1007/BF02651606

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02651606