Abstract

A model is presented to predict the columnar to equiaxed transition (CET) in alloy castings. The model is based on a multiphase approach and accounts for heat and solute diffusion, as well as for grain nucleation, growth, and morphology. The model equations are applicable to both columnar and equiaxed dendritic solidification, thus offering an efficient single-domain formulation. A fixed grid, fully implicit finite-difference procedure is employed in the numerical solution, and a novel front tracking technique is incorporated that is also implicit in nature and readily applies to multidimensional situations. Calculations are performed for one-dimensional (1-D) and two-dimensional (2-D) castings of Al-Cu and Sn-Pb alloys. The calculated CET positions are compared with previous measurements in a (1-D) ingot cast under well-controlled conditions, and good agreement is found. The effects of various casting parameters on the CET are numerically explored.

Similar content being viewed by others

Abbreviations

- a :

-

constant in Eq. [11], m (K/s)1/3

- C :

-

concentration of a chemical species, wt Pct

- C P :

-

volumetric specific heat, J/m3 · K

- D :

-

mass diffusion coefficient, m2/s

- G :

-

temperature gradient, K/m

- h :

-

chill heat-transfer coefficient, W/m2 · K

- H :

-

enthalpy, J/m3

- Iv :

-

Ivantsov function

- k :

-

thermal conductivity, W/m · K

- l :

-

solute diffusion length, m

- L :

-

casting length, m

- m 1 :

-

liquidus line slope, K/wt Pct

- n :

-

equiaxed nuclei density, m-3

- Pe :

-

envelope Peclet number, wneRf/Dl

- Pe t :

-

tip Peclet number, VtRt/(2Dl)

- R :

-

radius, m

- S :

-

interfacial area concentration, m-1

- t :

-

time, s

- T :

-

temperature, K

- T :

-

cooling rate, dT/dt, K/s

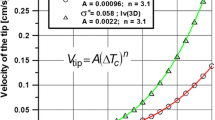

- V t :

-

dendrite tip velocity, m/s

- w ne :

-

envelope velocity, m/s

- x :

-

axial distance, m

- y :

-

coordinate, m

- α :

-

angle of columnar grains with respect to the axial direction

- Γ:

-

Gibbs-Thomson coefficient in the growth model for dendrite tips, kg/m3 · s

- δt:

-

smaller time step, s

- Δh:

-

latent heat of phase change, J/m3

- Δt:

-

larger time step, s

- ΔT0 :

-

pouring superheat, T0-TL(C0), K

- ΔTN :

-

nucleation undercooling, K

- ε:

-

volume fraction

- k :

-

partition coefficient, wt pct/wt Pct

- λ:

-

dendrite arm spacing, μm

- ϕe :

-

shape factor of the dendrite envelope, ϕe = 1 in this article

- Ω:

-

solutal supersaturation, (Ce - 〈C1〉1)/[Ce(1- k)

- a :

-

ambient

- cf :

-

columnar front

- d :

-

interdendritic liquid

- e :

-

dendrite envelope

- E :

-

eutectic point

- f :

-

final

- l :

-

extradendritic liquid

- L :

-

liquidus

- Id :

-

extradendritic/interdendritic liquid interface

- m :

-

melting point of pure metals

- nb :

-

neighboring coefficients in the discretized energy equation, see Patankar[25]

- O :

-

initial state

- P :

-

nodal point

- s :

-

solid

- sd :

-

solid-interdendritic liquid interface

- t :

-

dendrite tip

References

B. Chalmers:Principles of Solidification, John Wiley, New York, NY, 1964.

A. Ohno:Solidification: The Separation Theory and Its Practical Applications, Springer-Verlag, Berlin, 1987.

W. Kurz and D.J. Fisher:Fundamentals of Solidification, Trans. Tech. Publications, Switzerland, 1989.

S.G.R. Brown and J.A. Spittle:Mater. Sci. Technol, 1989, vol. 5, pp. 362–68.

J.D. Hunt:Mater. Sci. Eng., 1984, vol. 65, pp. 75–83.

S.C. Flood and J.D. Hunt:Appl. Sci. Res., 1987, vol. 44, pp. 27–42.

S.C. Flood and J.D. Hunt:J. Crystal Growth, 1987, vol. 82, pp. 552–60.

M. Rappaz:Int. Met. Rev., 1989, vol. 34, pp. 93–123.

B. Giovanola and W. Kurz:Metall. Trans. A, 1990, vol. 21A, pp. 260–63.

P. Zhu and R.W. Smith:Acta Metall. Mater., 1992, vol. 40, pp. 3369–79.

M. Rappaz and Ch.-A. Gandin:Acta Metall. Mater., 1993, vol. 41, pp. 345–60.

R.B. Mahapatra and F. Weinberg:Metall. Trans. B, 1987, vol. 18B, pp. 425–32.

I. Ziv and F. Weinberg:Metall. Trans. B, 1989, vol. 20B, pp. 731–34.

F. Weinberg: inProc. F. Weinberg Int. Symp. on Solidification Processing, J.E. Lait and I.V. Samarasekera, eds., Pergamon Press, New York, NY, 1990, pp. 3–11.

C.Y. Wang and C. Beckermann:Metall. Trans. A, 1993, vol. 24A, pp. 2787–2802.

C.Y. Wang and C. Beckermann:Mater. Sci. Eng. A, 1993, vol. A171,pp. 199–211.

W. Kurz, B. Giovanola, and R. Trivedi:Acta Metall., 1986, vol. 34, pp. 823–30.

J. Lipton, M.E. Glicksman, and W. Kurz:Mater. Sci. Eng., 1984, vol. 65, pp. 57–63.

D.M. Stefanescu, G. Upadhya, and D. Bandyopadhyay:Metall. Trans. A, 1990, vol. 21A, pp. 997–1005.

J.D. Hunt:Solidification and Casting of Metals, Metals Society, London, 1979.

W. Kurz and D.J. Fisher:Acta Metall., 1981, vol. 29, pp. 11–20.

H. Jones:Mater. Sci. Eng., 1984, vol. 65, pp. 145–56.

M. Rappaz and Ph. Thevoz:Acta Metall., 1987, vol. 35, pp. 1487–97.

Ph. Thevoz, J.L. Desbiolles, and M. Rappaz:Metall. Trans. A, 1989, vol. 20A, pp. 311–22.

S.V. Patankar:Numerical Heat Transfer and Fluid Flow, Hemisphere Publishing Corp., New York, NY, 1980.

A.A. Tseng, J. Zou, H.P. Wang, and S.R.H. Hoole:J. Comput. Phys., 1992, vol. 102, pp. 1–17.

V.R. Voller:Numer. Heat Transfer, Part B, 1990, vol. 17, pp. 155–69.

T.P. Battle and R.D. Pehlke:Metall. Trans. B, 1990, vol. 21B, pp. 357–75.

D.R. Poirier:Metall. Trans. A, 1988, vol. 19A, pp. 2349–54.

M. Gunduz and J.D. Hunt:Acta Metall., 1985, vol. 33, pp. 1651–72.

J. Lipton, W. Heinemann, and W. Kurz:Arch. Eisenhüttenwes., 1984, vol. 55, pp. 195–200.

S.G.R. Brown and J.A. Spittle: inModeling of Casting, Welding and Advanced Solidification Processes V, M. Rappaz, M.R. Ozgu, and K.W. Mahin, eds., TMS-AIME, Warrendale, PA, 1991, pp. 395–402.

V.K. Suri, N. El-Kaddah, and J.T. Berry:AFS Trans., 1991, vol. 99, pp. 187–91.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, C.Y., Beckermann, C. Prediction of Columnar to Equiaxed Transition during Diffusion-Controlled Dendritic Alloy Solidification. Metall Mater Trans A 25, 1081–1093 (1994). https://doi.org/10.1007/BF02652282

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02652282